Defining Contact Pairs

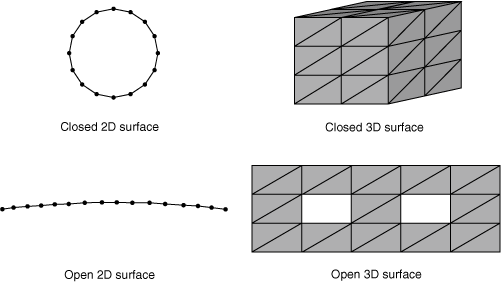

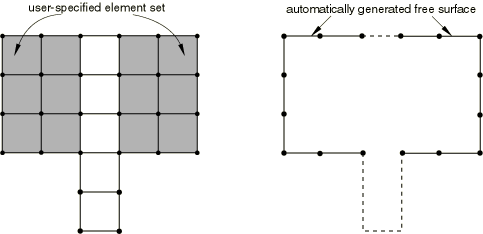

To define a contact pair, you must indicate which pairs of surfaces may interact with one another or which surfaces may interact with themselves. Contact surfaces should extend far enough to include all regions that may come into contact during an analysis; however, including additional surface nodes and faces that never experience contact may result in significant extra computational cost (for example, extending a secondary surface such that it includes many nodes that remain separated from the main surface throughout an analysis can significantly increase memory usage unless penalty contact enforcement is used).

Every contact pair is assigned a contact formulation (either explicitly or by default) and must refer to an interaction property. Discussion of the various available contact formulations (based on whether the tracking approach assumes finite- or small-sliding—and whether the contact discretization is based on a node-to-surface or surface-to-surface approach) is provided in Contact Formulations in Abaqus/Standard. Interaction property definitions are discussed in Assigning Contact Properties for Contact Pairs in Abaqus/Standard.

Defining Contact between Two Separate Surfaces

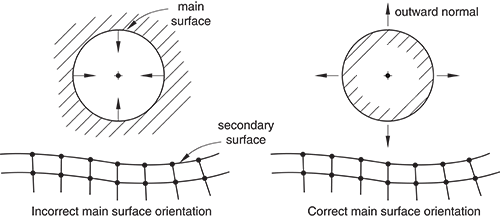

When a contact pair contains two surfaces, the two surfaces are not allowed to include any of the same nodes and you must choose which surface will be the secondary and which will be the main. The selection of main and secondary surfaces is discussed in detail in Choosing the Main and Secondary Surface Roles in a Two-Surface Contact Pair. For simple contact pairs consisting of two deformable surfaces, the following basic guidelines can be used:

-

The larger of the two surfaces should act as the main surface.

-

If the surfaces are of comparable size, the surface on the stiffer body should act as the main surface.

-

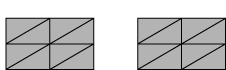

If the surfaces are of comparable size and stiffness, the surface with the coarser mesh should act as the main surface.

The finite-sliding, node-to-surface formulation is used by default (except in Abaqus/CAE, where the default is the finite-sliding, surface-to-surface formulation).

Defining Contact Pairs Using the Finite-Sliding, Node-to-Surface Formulation

A finite-sliding, node-to-surface formulation is available.

Input File Usage

CONTACT PAIR, INTERACTION=interaction_property_name secondary_surface_name, main_surface_name

You can also specify the contact discretization directly:

CONTACT PAIR, INTERACTION=interaction_property_name, TYPE=NODE TO SURFACE secondary_surface_name, main_surface_name

Abaqus/CAE Usage

Interaction module: Create Interaction: Surface-to-surface contact (Standard): select the main surface, click Surface or Node Region, select the secondary surface, Interaction editor, Sliding formulation: Finite sliding, Discretization method: Node to surface, Contact interaction property: interaction_property_name

Defining Contact Pairs Using the Finite-Sliding, Surface-to-Surface Formulation

A node-based secondary surface precludes the use of surface-to-surface discretization. Some contact capabilities are not available with the finite-sliding, surface-to-surface formulation, including crack propagation (see Crack Propagation Analysis).

Input File Usage

Use the following option to define contact constraints using the finite-sliding, surface-to-surface formulation:

CONTACT PAIR, INTERACTION=interaction_property_name, TYPE=SURFACE TO SURFACE secondary_surface_name, main_surface_name

Abaqus/CAE Usage

Interaction module: Create Interaction: Surface-to-surface contact (Standard): select the main surface, click Surface, select the secondary surface, Interaction editor, Sliding formulation: Finite sliding, Discretization method: Surface to surface, Contact interaction property: interaction_property_name

Defining Contact Pairs Using the Small-Sliding, Node-to-Surface Formulation

The small-sliding tracking approach uses node-to-surface discretization by default. For an explanation of when the small-sliding tracking approach is appropriate in an analysis, see Using the Small-Sliding Tracking Approach.

Input File Usage

CONTACT PAIR, INTERACTION=interaction_property_name, SMALL SLIDING secondary_surface_name, main_surface_name

You can also specify the contact discretization directly:

CONTACT PAIR, INTERACTION=interaction_property_name, SMALL SLIDING, TYPE=NODE TO SURFACE secondary_surface_name, main_surface_name

Abaqus/CAE Usage

Interaction module: Create Interaction: Surface-to-surface contact (Standard): select the main surface, click Surface or Node Region, select the secondary surface, Interaction editor, Sliding formulation: Small sliding, Discretization method: Node to surface, Contact interaction property: interaction_property_name

Defining Contact Pairs Using the Small-Sliding, Surface-to-Surface Formulation

A node-based secondary surface precludes the use of surface-to-surface discretization.

Input File Usage

CONTACT PAIR, INTERACTION=interaction_property_name, SMALL SLIDING, TYPE=SURFACE TO SURFACE secondary_surface_name, main_surface_name

Abaqus/CAE Usage

Interaction module: Create Interaction: Surface-to-surface contact (Standard): select the main surface, click Surface, select the secondary surface, Interaction editor, Sliding formulation: Small sliding, Discretization method: Surface to surface, Contact interaction property: interaction_property_name

Using Symmetric Main-Secondary Contact Pairs to Improve Contact Modeling

For node-to-surface contact it is possible for main surface nodes to penetrate the secondary surface without resistance with the strict main-secondary algorithm used by Abaqus/Standard. This penetration tends to occur if the main surface is more refined than the secondary surface or a large contact pressure develops between soft bodies. Refining the secondary surface mesh often minimizes the penetration of the main surface nodes. If the refinement technique does not work or is not practical, a symmetric main-secondary method can be used if both surfaces are element-based surfaces with deformable or deformable-made-rigid parent elements. To use this method, define two contact pairs using the same two surfaces, but switch the roles of main and secondary surface for the two contact pairs. This method causes Abaqus/Standard to treat each surface as a main surface and, thus, involves additional computational expense because contact searches must be conducted twice for the same contact pair. The increased accuracy provided by this method must be compared to the additional computational cost.

All of the contact formulations are available for symmetric main-secondary contact pairs, and can be applied using the same options discussed above.

Input File Usage

CONTACT PAIR, INTERACTION=interaction_property_name surface_1, surface_2 surface_2, surface_1

Abaqus/CAE Usage

Interaction module: Create Interaction: Surface-to-surface contact (Standard): select the main surface, click Surface, select the secondary surface Copy this interaction to a new interaction, and edit the new interaction. In the interaction editor, click Switch to reverse the main and secondary surfaces.

Limitations of Symmetric Main-Secondary Contact Pairs

Using symmetric main-secondary contact pairs can lead to overconstraint problems when very stiff or hard contact conditions are enforced. See Contact Constraint Enforcement Methods in Abaqus/Standard for a discussion of overconstraints and alternate constraint enforcement methods.

For softened contact conditions, use of symmetric main-secondary contact pairs will cause deviations from the specified pressure-versus-overclosure behavior, because both contact pairs contribute to the overall interface stress without accounting for one another. For example, symmetric main-secondary contact pairs effectively double the overall contact stiffness if a linear pressure-overclosure relationship is specified.

Likewise, use of symmetric main-secondary contact pairs will cause deviations from the friction model if an optional shear stress limit is specified (see Using the Optional Shear Stress Limit), because the contact stresses observed by each contact pair will be approximately one-half of the total interface stress.

Similarly, it can be difficult to interpret the results at the interface for symmetric main-secondary contact pairs. In this case both surfaces at the interface act as secondary surfaces, so each has contact constraint values associated with it. The constraint values that represent contact pressures are not independent of each other. Therefore, the constraint values reported in the data (.dat) and results (.fil) files represent only a part of the total interface pressure and have to be summed to obtain the total.

In the output database, mechanical contact variables are reported at the nodes on both the main and secondary surfaces per contact pair and not just the secondary surface where constraints are formed. Consequently, two result sets are available per surface of a symmetric main-secondary contact pair; once when a surface acts as a secondary and once as a main. For nodal contact pressures the Visualization module of Abaqus/CAE only reports the maximum of the two pressure values associated with a node when the surface containing the node acts either as a main or as a secondary surface. Even in this case, the contact pressures do not represent the true interface pressure.

Apart from contact pressures, some contact output may be confusing with symmetric main-secondary contact pairs. For example, Abaqus/Standard may report a positive opening distance on one side of a contact interface but zero opening distance (i.e., touching) on the opposite side of the interface. Typically this is caused by the shape or relative mesh refinement of the two surfaces.

Defining Self-Contact

Define contact between a single surface and itself by specifying only a single surface or by specifying the same surface twice. The small-sliding tracking approach cannot be used with self-contact.

Defining Self-Contact Using Node-to-Surface Discretization

Abaqus/Standard uses node-to-surface contact discretization by default for self-contact.

Input File Usage

Use either of the following options:

CONTACT PAIR, INTERACTION=interaction_property_name surface_1,

CONTACT PAIR, INTERACTION=interaction_property_name surface_1, surface_1

Abaqus/CAE Usage

Interaction module: Create Interaction: Self-contact (Standard): select the surface Interaction editor, Discretization method: Node to surface, Contact interaction property: interaction_property_name

or

Interaction module: Create Interaction: Surface-to-surface contact (Standard): select the surface, click Surface, select the surface again Interaction editor, Sliding formulation: Finite sliding, Discretization method: Node to surface, Contact interaction property: interaction_property_name

Defining Self-Contact Using Surface-to-Surface Discretization

Surface-to-surface discretization often leads to more accurate modeling of self-contact simulations. However, because the self-contact surface is acting as both a main and a secondary, surface-to-surface discretization can sometimes significantly increase the solution cost.

Input File Usage

Use either of the following options:

CONTACT PAIR, INTERACTION=interaction_property_name, TYPE=SURFACE TO SURFACE surface_1,

CONTACT PAIR, INTERACTION=interaction_property_name, TYPE=SURFACE TO SURFACE surface_1, surface_1

Abaqus/CAE Usage

Interaction module: Create Interaction: Self-contact (Standard): select the surface Interaction editor, Discretization method: Surface to surface, Contact interaction property: interaction_property_name

or

Interaction module: Create Interaction: Surface-to-surface contact (Standard): select the surface, click Surface, select the surface again Interaction editor, Sliding formulation: Finite sliding, Discretization method: Surface to surface, Contact interaction property: interaction_property_name

Limitations of Self-Contact

Self-contact is valid only for mechanical surface interactions and is limited to finite sliding with element-based surfaces.

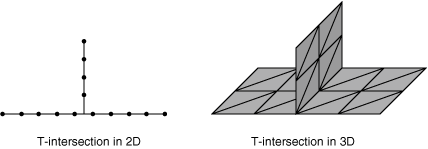

A node of a self-contact surface can be both a secondary node and a member of the main surface for two-dimensional self-contact using the surface-to-surface formulation and for all three-dimensional self-contact. In these cases the contact behavior is similar to symmetric main-secondary contact pairs, and the issues discussed in Using Symmetric Main-Secondary Contact Pairs to Improve Contact Modeling apply. Abaqus/Standard automatically applies some numerical softening to contact conditions in these cases, as discussed in Contact Constraint Enforcement Methods in Abaqus/Standard.

Direct enforcement of hard contact conditions is the default constraint enforcement method for two-dimensional self-contact using the node-to-surface formulation. In this case, each node adjacent to a vertex where a two-dimensional surface folds onto itself is automatically assigned a secondary or main role during the analysis. Since contact constraints directly resist penetrations at nodes that act as secondary nodes, there is some possibility of unresolved penetrations at nodes that only act as main nodes for two-dimensional self-contact using the node-to-surface formulation.