Two

Abaqus

methods that are particularly useful for analyzing threaded connectors are the

specification of an allowable contact interference and of pressure penetration

loads.

The automatic “shrink” fit method can be used to automatically resolve

the overclosure of two contacting surfaces. This method is applicable only

during the first step of an analysis, and it cannot be used with self-contact.

See

Modeling Contact Interference Fits in Abaqus/Standard

for details.

The surface-based pressure penetration capability described in Fluid Pressure Penetration Loads is used to simulate pressure penetration between

contacting surfaces. This capability is provided for simulating cases where a joint

between two deforming bodies (for example, between two components threaded onto each

other) or between a deforming body and a rigid surface (such as a soft gasket used in a

joint) is exposed at one or multiple ends to a fluid pressure. This pressure will

penetrate into the joint and load the surfaces forming the joint until some area of the

surfaces is reached where the contact pressure between the abutting surfaces exceeds the

critical value specified in the pressure penetration load, cutting off further

penetration.

The contact output variables in

Abaqus

can provide the designer a wealth of information about the performance of a

connector during all steps of an analysis. When modeling surface-based contact

with axisymmetric elements (CAX- and CGAX-type elements) an output quantity of particular use is the

maximum torque that can be transmitted about the z-axis by

a specified contact pair. The maximum torque, T, is a

scalar value defined as

where p is the pressure transmitted across the interface,

r is the radius to a point on the interface, and s

is the current distance along the interface in the

r–z plane. T is not a real

torque; it is a computed limit of torque that a contact pair may transmit about the

z-axis assuming that all the secondary nodes on the contact surface are

slipping and that the friction coefficient is set to 1. The actual maximum torque that can be

transmitted about the z-axis by a specified contact pair can be estimated

by scaling T by the friction coefficient specified for the contact pair.

The value of T can be output by requesting the contact output variable

CTRQ.

This example demonstrates the usefulness of the specification of allowable

contact interference and of pressure penetration loads as well as the

Abaqus

contact output variables in an axisymmetric analysis of a particular threaded

connector.

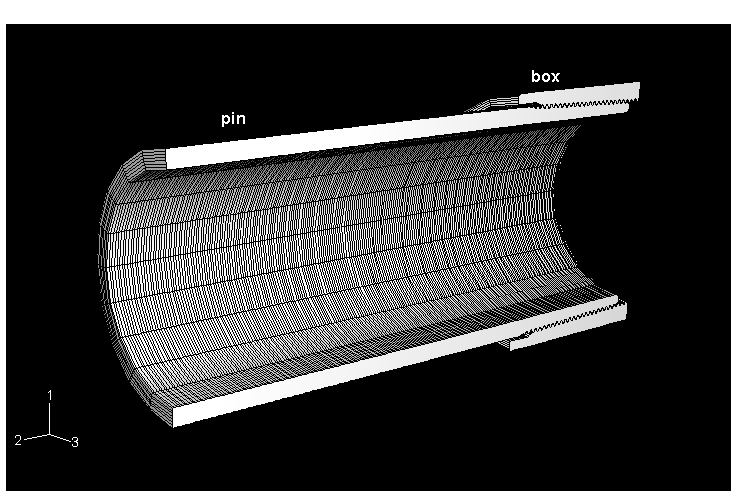

Geometry and model

A three-dimensional cut-away view of the threaded connection assembly

analyzed in this example is shown in

Figure 1.

Although the actual threads are helical, they are represented with an

axisymmetric geometry. Previous experience has shown this simplification to be

appropriate for these types of problems. Both the “pin” and the “box” are made

from steel with a Young's modulus of 207 GPa (30 × 106 psi) and a

Poisson's ratio of 0.3, which is characterized by a von Mises plasticity model.

The unthreaded section of the pin has inner and outer radii of 48.6 mm (1.913

in) and 57.2 mm (2.25 in), respectively. The major diameter of the threads on

the pin (diameter measured at the crest of the threads) is slightly larger than

the major diameter of the threads on the box (diameter measured at the roots of

the threads); thus, there is an initial interference between the threads on the

pin and on the box.

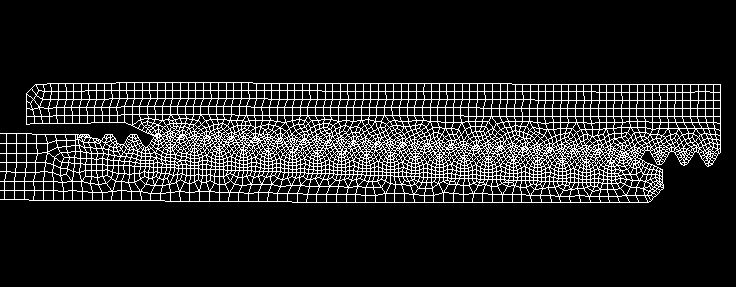

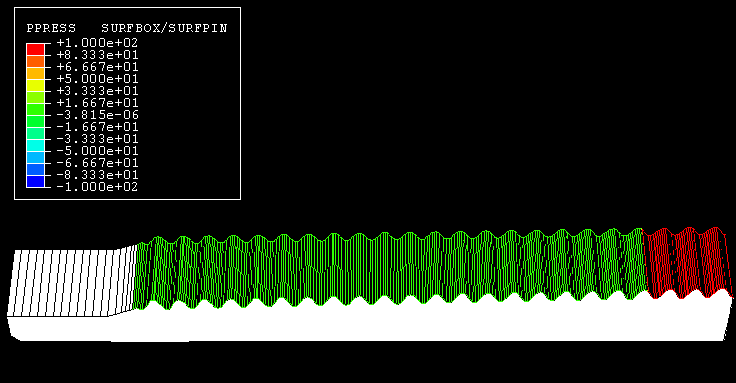

The deformed axisymmetric mesh (after the initial interference has been

resolved) in the vicinity of the threads is illustrated in

Figure 2.

Contact is modeled by the interaction of contact surfaces defined by grouping

specific faces of the elements in the contacting regions.

Loading and boundary conditions

Two analyses of the threaded connection are performed: an axisymmetric

analysis using CAX4 elements and an axisymmetric analysis with twist using CGAX4 elements. The first four steps for the two analyses are

identical. The CGAX4 model has an additional fifth step.

The initial interference fit of the threads on the pin and box is resolved

in the first step using the automatic “shrink” fit method with a friction

coefficient of 0. In the second step the assembly is held fixed while the

friction coefficient is changed from 0 to 0.1 using changes to friction

properties. An internal gauge pressure of 0.689 MPa (100 psi) is applied to the

connector in the third step. The pressure on the contact surfaces is applied

using pressure penetration loading. In the first three steps the displacements

in the 2-direction are constrained to be zero at both ends of the assembly. To

simulate an axial load in the fourth step, a displacement boundary condition of

−0.254 cm (−0.1 in) is applied to the end of the box in the 2-direction. In the

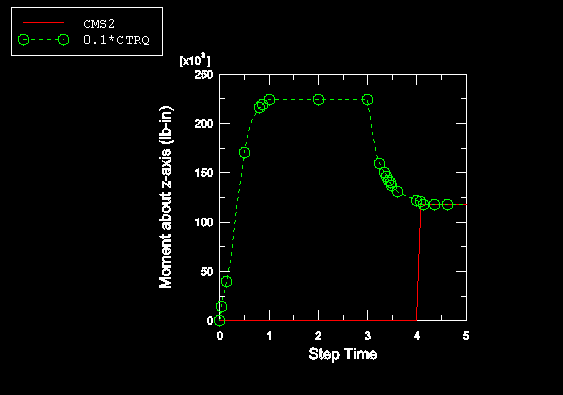

fifth step for the CGAX4 model the end of the pin is held fixed while the end of the box

is rotated 0.1 radians about the 2-axis, simulating a torque being applied to

the connector. The actual torques generated about the 2-axis by the frictional

stresses in the fifth step are given by the output variable CMS2. This value is compared to the estimated value given by CTRQ for the fourth step.

Results and discussion

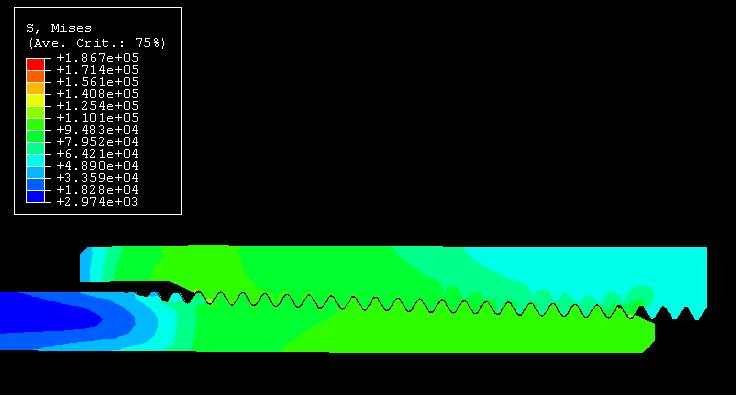

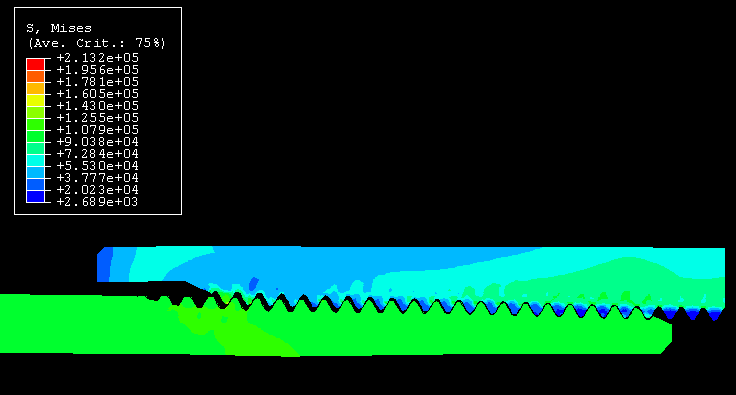

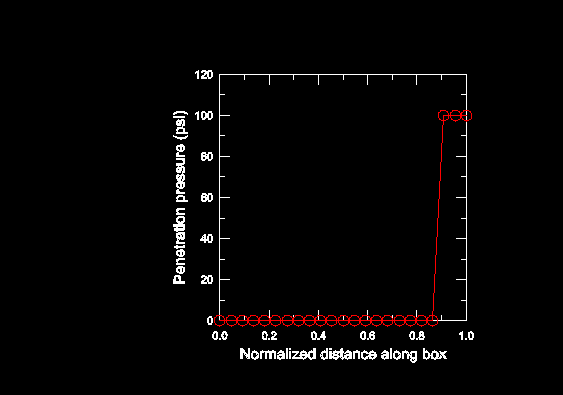

All analyses are performed as large-displacement analyses. The results from the first four steps

for both models are identical. Figure 3 and Figure 4, respectively, show the von Mises stress distributions in the threaded assembly after the

overclosure has been resolved in Step 1 and after the displacement boundary condition has

been applied in Step 4. As is illustrated in Figure 4, some of the threads on the pin are beginning to pull out at the end of Step 4. However,

plots of the pressure penetration on the contact surface of the box in Figure 5 and Figure 6 show that the seal of the threads is maintained; thus, no leakage is indicated. If the

seal had failed, the penetration pressure on the box surface in contact with the pin would

be 0.689 MPa (100 psi) instead of 0. Other contact output variables such as

CPRESS and

COPEN provide additional information about

the contact state throughout the analysis.

The scaled values of CTRQ (scaled by the friction coefficient of 0.1) and the values of CMS2 for all five steps in the CGAX4 analysis are illustrated in

Figure 7.

The value of CTRQ at the end of Step 4 is 1.22 × 106 lb-in, which

translates into an estimated maximum torque of 1.22 × 105 lb-in for

a friction coefficient of 0.1. The value of CMS2 computed during Step 5 for the CGAX4 model is 1.18 × 105 lb-in. The 3.7% difference in this

example between the predicted and actual torque values can be attributed to a

slight change in the normal pressure distribution between the contact surfaces

that occurs when the box is rotated. The value of CMS2 is zero for the first four steps since no frictional stresses

are generated between the contact surfaces until the fifth step. The value of CTRQ increases in the first step as the overclosure is resolved and

dips in the fourth step due to the change in the contact pressure as the box is

pulled away from the pin (see

Figure 7).