Defining Connector Stops

In the physical construction of most connectors, the admissible position of one body relative to the other is limited by a certain range. In Abaqus these limits are modeled as built-in inequality constraints. You specify the available components of relative motion for which the connector stops are to be defined and the lower and upper limit values of the connector's admissible range of positions in the directions of the components of relative motion.

Input File Usage

Use the following options to define a connector stop:

CONNECTOR BEHAVIOR, NAME=name CONNECTOR STOP, COMPONENT=component number lower limit, upper limit

Abaqus/CAE Usage

Interaction module: connector section editor: : Components: component or components, Lower bound: lower limit, Upper bound: upper limit

Example

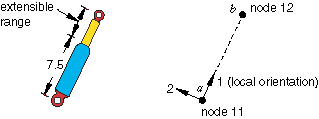

Since the shock in Figure 1 has finite length, contact with the ends of the shock determines the upper and lower limit values of the distance that node b can be from node a.

Assume that the maximum length of the shock is 15.0 units and that the minimum length is 7.5 units. Modify the input file presented in About Connectors that is associated with the example in Figure 1 to include the following lines:

CONNECTOR BEHAVIOR, NAME=sbehavior ... CONNECTOR STOP, COMPONENT=1 7.5, 15.0