Defining Viscous Contact Damping for Relative Motions of Surfaces

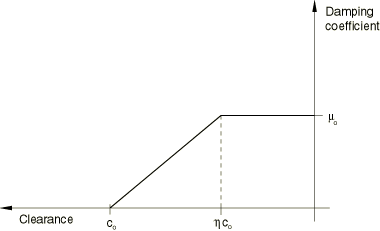

In Abaqus/Standard the damping coefficient, , is a function of surface clearance, as shown in Figure 1. The damping coefficient is defined as a proportionality constant with units of pressure divided by velocity.

In Abaqus/Explicit the damping coefficient will remain at the specified constant value while the surfaces are in contact and at zero otherwise. The damping coefficient can be defined as a proportionality constant with units of pressure divided by velocity or as a unitless fraction of critical damping.

To define viscous damping, you must include it in a contact property definition.

Input File Usage

Use both of the following options for surface-based contact:

SURFACE INTERACTION, NAME=interaction_property_name CONTACT DAMPING

Use both of the following options for element-based contact in Abaqus/Standard:

INTERFACE or GAP, ELSET=name CONTACT DAMPING

Abaqus/CAE Usage

Interaction module: contact property editor: Element-based contact is not supported in Abaqus/CAE.

Damping and Pressure-Overclosure Relationships

In Abaqus/Standard the viscous damping relationship can be used with any contact relationship (see Contact Pressure-Overclosure Relationships).

In Abaqus/Explicit contact damping is not available for hard kinematic contact. Softened kinematic contact and all penalty contact will have default damping in the form of a critical damping fraction with = 0.03.

Specifying the Damping Coefficient Such That the Damping Force Is Directly Proportional to the Rate of Relative Motion between the Surfaces

You can specify damping directly in terms of the damping coefficient with units of pressure per velocity such that the damping forces will be calculated with , where A is the nodal area and is the rate of relative motion between the two surfaces.

For contact involving element-based surfaces and for element-based contact (available only in Abaqus/Standard), the damping coefficient is specified in terms of contact pressure. For contact involving a node-based surface or nodal contact elements (such as GAP elements and ITT elements) for which an area or length dimension has not been defined, must be specified as force per velocity. For secondary surfaces on beam-type elements, specify as force per unit length per velocity.

Input File Usage

Use the following syntax in Abaqus/Standard:

CONTACT DAMPING, DEFINITION=DAMPING COEFFICIENT , ,

Use the following syntax in Abaqus/Explicit:

CONTACT DAMPING, DEFINITION=DAMPING COEFFICIENT

Abaqus/CAE Usage

Use the following syntax in Abaqus/Standard:

Interaction module: contact property editor: : Definition: Damping coefficient, Linear or Bilinear, Damping Coeff. , Clearance c and (=0 for Linear and for Bilinear)

Use the following syntax in Abaqus/Explicit:

Interaction module: contact property editor: : Definition: Damping coefficient, Step, Damping Coeff.

Specifying the Damping Coefficient as a Fraction of Critical Damping in Abaqus/Explicit

In Abaqus/Explicit you can specify a unitless damping coefficient in terms of the fraction of critical damping associated with the contact stiffness; this method is not available in Abaqus/Standard. The damping forces will be calculated with , where m is the nodal mass, is the nodal contact stiffness (in units of ), and is the rate of relative motion between the two surfaces.

Input File Usage

CONTACT DAMPING, DEFINITION=CRITICAL DAMPING FRACTION critical damping fraction

Abaqus/CAE Usage

Interaction module: contact property editor: : Definition: Critical damping fraction, Crit. Damping Fraction critical damping fraction

Specifying the Tangential Damping Coefficient

You can specify the ratio of the tangential damping coefficient to the normal damping coefficient, also called the tangent fraction.

The tangential damping uses the same form of damping as the normal damping. Tangential damping can be specified only in conjunction with normal damping. If tangential damping is activated in Abaqus/Standard, the damping stress is proportional to the relative tangential velocity. In Abaqus/Explicit tangential damping will be ignored if hard kinematic contact is used in the tangential direction or if friction is not defined. As stated previously, damping in the tangential direction in Abaqus/Explicit is proportional to the elastic slip rate (see Frictional Behavior) rather than the total rate of relative sliding.

For Abaqus/Standard the default value for the tangent fraction is 0.0; therefore, by default, the damping coefficient for the tangential direction is zero. For Abaqus/Explicit the default value for the tangent fraction is 1.0; therefore, by default, the damping coefficient for the tangential direction is equal to the damping coefficient for the normal direction. Furthermore, in Abaqus/Explicit softened contact and hard penalty contact have a default critical damping fraction of 0.03.

Input File Usage

CONTACT DAMPING, TANGENT FRACTION=value

Abaqus/CAE Usage

Interaction module: contact property editor: : Tangent fraction: Specify value: value

Effect on the Increment Time in Abaqus/Explicit

Abaqus/Explicit accounts for the contact damping in the stable time increment calculation. Changing the default value might cause a significant drop in the stable time increment and, therefore, an increase in the solution time. Optionally, you can introduce contact mass scaling to the surface nodes in contact to avoid a reduction in the time increment (for more information, see Mass Scaling to Account for Contact Stiffness).