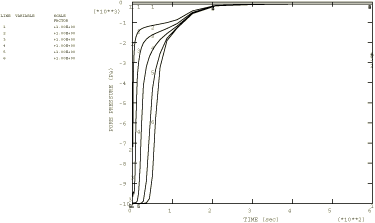

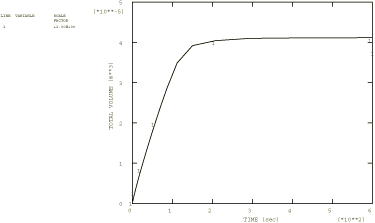

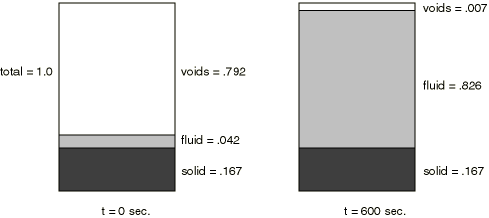

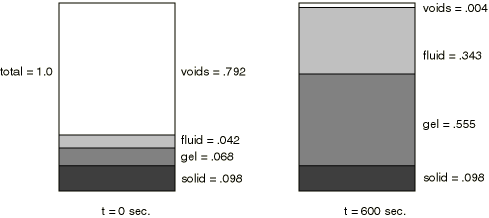

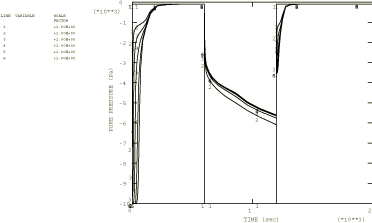

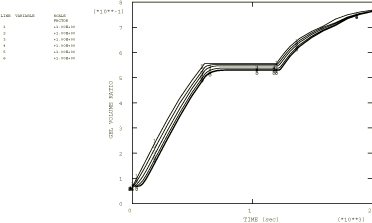

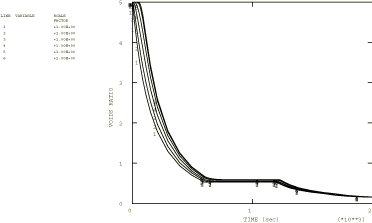

The “loading” consists of prescribing a zero pore pressure (corresponding to

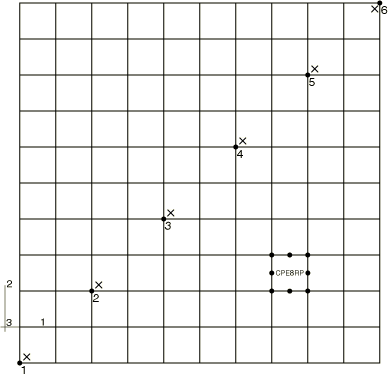

full saturation) at the center of the sample, node 1 in

Figure 1.

This is based on the assumption that, in the demand wettability test, the

sample has available to it as much fluid as necessary to cause saturation at

that point. This boundary condition is held fixed for 600 seconds to model the

fluid acquisition process. Then a draining period of 600 seconds is modeled by

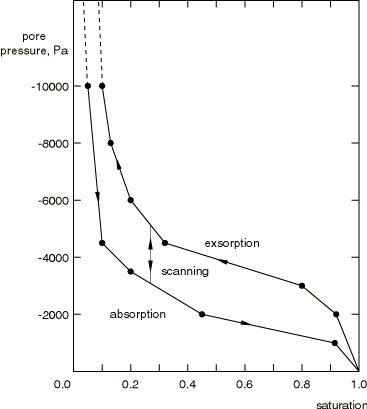

prescribing a pore pressure of −10 kPa at node 1; this corresponds to a

saturation of 10%, which is the least saturation the sample can achieve after

it has been wetted (see

Figure 2).

The draining procedure we use is not physically realistic, since the free fluid

saturation cannot drop to 10% instantaneously as we assume. Nevertheless, it

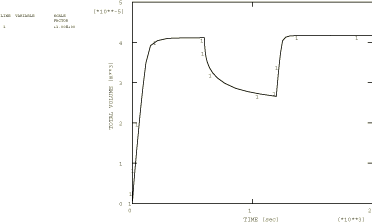

serves to illustrate the behavior of the model. Finally, we model the rewetting

process over a time period of 800 seconds in the third step of analysis by once

again prescribing zero pressure at the center of the sample.

The analysis is performed with a transient soils consolidation procedure

(Coupled Pore Fluid Diffusion and Stress Analysis)

using automatic time incrementation. The pore pressure tolerance that controls

the automatic incrementation is set to a large value since we expect the

nonlinearity of the material to restrict the size of the time increments during

the transient stages of the analysis and we do not wish to impose any further

control on the accuracy of the time integration. The volume flux tolerance that

controls the accuracy of the solution of the flow continuity equations is set

to 1.0 × 10−8 m3/sec (Convergence Criteria for Nonlinear Problems).

This is less than 1% of the flux that occurs during the initial wetting stage

of the problem. The problem can also be run with the default tolerance. The

results obtained are unchanged. However, in this problem the default tolerances

calculated by

Abaqus

are extremely tight, resulting in additional iterations without benefit to the

solution. For this reason we define a less stringent tolerance.

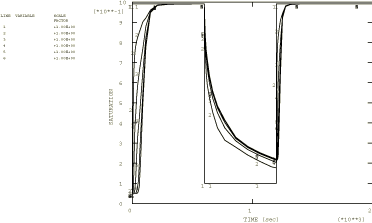

An important issue in these transient, partially saturated flow problems is

the choice of initial time step. As in any transient problem the spatial

element size and the time step are related, to the extent that time steps

smaller than a certain size give no useful information. This coupling of the

spatial and temporal approximations is always most obvious at the start of

diffusion problems, immediately after prescribed changes in the boundary

values. As discussed in

Coupled Pore Fluid Diffusion and Stress Analysis,

the criterion is

where

is the specific weight of the wetting liquid,

is the initial porosity of the material, k is the fully

saturated permeability of the material,

is the permeability-saturation relationship,

is the rate of change of saturation with respect to pore pressure as defined in

the absorption/exsorption material behavior (Sorption),

and is a

typical element dimension. For our model we have

5.08 mm (the size of an element side),

1.0 × 104 N/m3,

3.7 × 10−4 m/sec, ,

and

5/6. Near node 1, where we apply the boundary condition, we will approach full

saturation conditions early in the transient. If we choose a saturation of 0.9

and the corresponding

in the absorption curve, we can calculate a

of about 0.1 sec. We choose to start the analysis with a time increment of 1

sec.

If time increments smaller than the critical value are used, spurious

oscillations may appear in the solution (except when reduced-integration,

linear, or modified triangular elements are used, in which case

Abaqus

uses a special integration scheme for the wetting liquid storage term to avoid

this problem). If the problem requires analysis with smaller time increments

than the critical value, a finer mesh is required. Generally there is no upper

limit on the time step, except accuracy, since the integration procedure is

unconditionally stable.