Elastic and Plastic Behavior

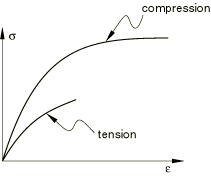

The cast iron plasticity model describes the mechanical behavior of gray cast iron, a material with a microstructure consisting of a distribution of graphite flakes in a steel matrix. In tension the graphite flakes act as stress concentrators, resulting in yielding as a function of the maximum principal stress, followed by brittle behavior. In compression the graphite flakes do not have an appreciable effect on the macroscopic response, resulting in a ductile behavior similar to that of many steels.

You specify the elastic part of the response separately; only linear isotropic elasticity can be used (see Linear Elastic Behavior). The elastic stiffness is assumed to be the same under tension and compression.

The cast iron plasticity model is used to provide the value of the plastic “Poisson's ratio,” which is the absolute value of the ratio of the transverse to the longitudinal plastic strain under uniaxial tension. The plastic Poisson's ratio can vary with the plastic deformation. However, the model in Abaqus assumes that it is constant with respect to plastic deformation. It can depend on temperature and field variables. If no value is specified for the plastic Poisson's ratio, a default value of 0.04 is assumed. This default value is based on experimental results for permanent volumetric strain under uniaxial tension (see Cast iron plasticity for details).

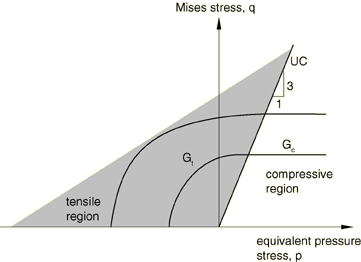

Independent hardening (see Figure 1) of the material under tension and compression can be specified as described below. The tension hardening data provide the uniaxial tension yield stress as a function of plastic strain, temperature, and field variables under uniaxial tension. The compression hardening data provide the uniaxial compression yield stress as a function of plastic strain, temperature, and field variables under uniaxial compression.

Input File Usage

CAST IRON PLASTICITY

Abaqus/CAE Usage

Property module: material editor: