The instantaneous and long-term behaviors provide a check on the

Abaqus

results. The instantaneous and long-term axial displacements of the rod tip can

be calculated as follows:

These values agree well with the

Abaqus

results. Similarly, the instantaneous and long-term values of the Poisson's

ratio can also be calculated exactly:

The Poisson's ratio can be extracted from the

Abaqus

results by taking the ratio of the lateral strain to the axial strain at

0.001 and

50:

Since this is an applied stress problem, obtaining the exact solution for

the entire time period of the analysis requires inverting the original

constitutive integral equation defining uniaxial stress in terms of uniaxial

strain. To perform this inversion, we use the following relation (Pipkin, 1972)

between the time-dependent relaxation modulus, ,

and the time-dependent creep compliance, :

Differentiation of this relation with respect to t

yields

With the previously used expression for

this takes the form

Differentiating this expression once more provides

Multiplying this equation by

and adding it to the previous equation yields the differential equation

With the introduction of the creep time constant

this can be written as:

The general solution to this differential equation is

where the coefficient C is defined by the initial

condition ,

which yields

For this problem the stress

is a constant, so that

From the values given above for ,

and ,

as well as the fact that 0.689

MPa (100 psi),

becomes

From this equation, it is evident that the effective time constant for the

problem is dramatically different (by a factor of 10 in this case), depending

upon whether the loading is applied force or applied displacement.

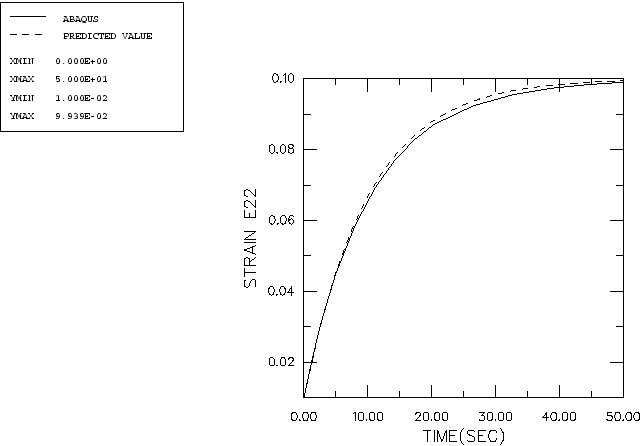

Figure 2

is a time history plot of

as predicted by the above equation and as calculated by

Abaqus.

The plot shows acceptable agreement between the

Abaqus

results and the exact solution. Closer agreement can be obtained by using a

smaller tolerance value for the maximum difference in the creep strain

increment over a time increment.

The solution obtained with the large-strain formulation differs negligibly

from the small-strain solution.

Abaqus

automatically converts frequency domain data into a time domain Prony series

representation. The analysis results using Prony parameters calibrated from

tabulated frequency-dependent moduli data are in good agreement with the

analyses using time domain data directly.