Problem description

The plate is shown in Figure 1. It is 914.4 mm (36 in) thick and has the following properties:

| Young's modulus | 206.8 GPa (30 × 106 lb/in2) |

| Poisson's ratio | 0.3 |

| Yield stress | 248.2 MPa for 121°C (36000 lb/in2, 250°F) |

| 248.2(1 − ( − 121)/1111.1) MPa, 121°C | |

| (36000(1 − ( − 250)/2000) lb/in2, 250°F) | |

| Density | 7832 kg/m3 (0.283 lb/in3) |

| Specific heat | 0.6 kJ/kg°C (0.1431 BTU/lb°F) |

| Thermal conductivity | 58.8 W/m°C (7.872 × 10−4 BTU/in sec°F) |

The film coefficient on the surface of the plate is 193.1 W/m2°C (6.559 × 10−5BTU/in2 sec°F).

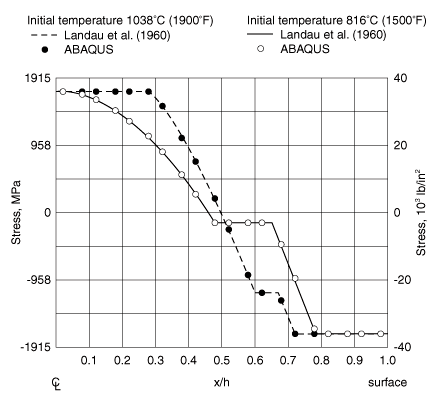

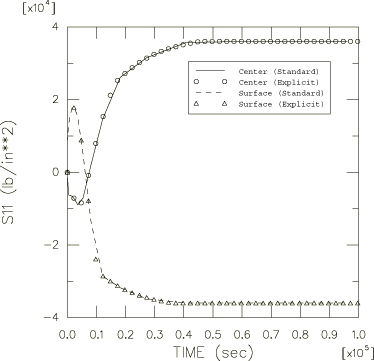

The finite element mesh used in the Abaqus/Standard simulations is shown in Figure 1. Ten elements are used through the half-thickness of the plate. Only one row of elements is needed since the problem is one-dimensional. No mesh convergence studies have been done: it is assumed that this mesh should give reasonably accurate results. This assumption is confirmed by the agreement with the results described by Landau et al. (1960). For the sequential thermal-stress analyses the heat transfer mesh uses elements of type DC2D8 (8-node quadrilaterals) and DC2D4 (4-node quadrilaterals). For the stress analysis the boundary conditions correspond to generalized plane strain in all directions that are normal to the surface of the plate; that is, any straight line that is initially perpendicular to the surface of the plate remains straight and perpendicular to the surface, but the distance between such lines varies as the plate cools. In the sequential thermal-stress analyses this condition is modeled using four element types: axisymmetric elements CAX8R and CAX4I and generalized plane strain elements CPEG4I and CPEG8R. To verify the interpolation technique between dissimilar meshes, the stress analysis using CAX8R elements is driven by the temperature field from the analysis using DC2D4 elements. In the fully coupled Abaqus/Standard simulations CPEG4HT, CPEG8RHT, CAX4T, and CAX4RT elements are used. The generalized plane strain elements have zero relative rotations prescribed between the planes that define the limits of the model in the thickness direction. (This condition is imposed by introducing boundary conditions at the reference node of these elements.) The generalized plane strain condition in the plane of the model is imposed in both models by using a symmetry condition on the left-hand edge of the mesh and an equation constraint to impose equal displacements at all nodes on the right-hand edge of the mesh.

Reduced-integration elements are used in all second-order models. Reduced integration is attractive because it decreases the analysis cost and, at the same time, provides more accurate stress predictions. Reduced integration is generally recommended when second-order elements are chosen.

In the Abaqus/Explicit simulations the axisymmetric plate is modeled with either CAX3T or CAX4RT elements; for the case where the plate is assumed to be in a state of generalized plane strain, C3D8RT elements are used with appropriate constraints to ensure that plane sections remain plane. In each case 20 elements are used through the half-thickness of the plate. Mass scaling is used to reduce the computational cost of the analyses.