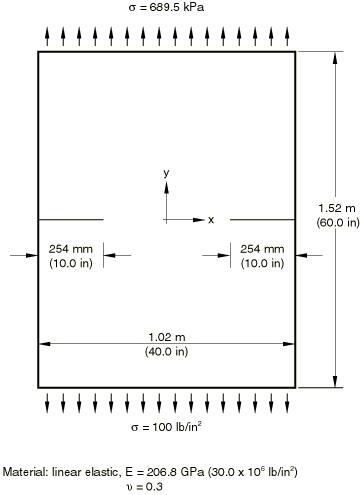

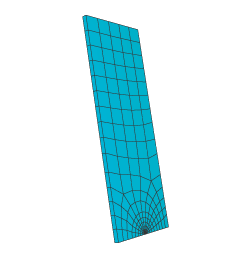

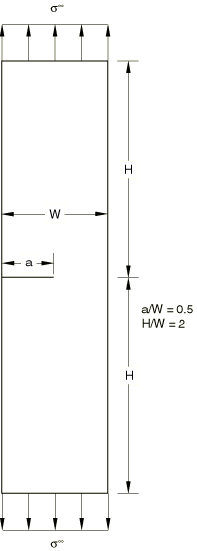

The geometry of the first example is shown in

Figure 1.

The plane strain structure is a section of a plate with symmetric edge cracks

at its centerline, leaving an uncracked ligament of half the plate's width. The

specimen is loaded in Mode I by uniform tension applied to its top and bottom

surfaces. When the conventional finite element method is used, symmetry about

x = 0 and about y = 0 can be used to

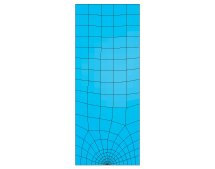

model only the top right-hand quadrant of the plate. The mesh used for the

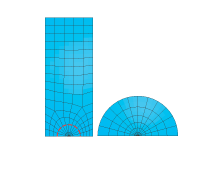

quarter model is shown in

Figure 2.

Second-order elements (8-node quadrilaterals, 20-node bricks) are used. In the

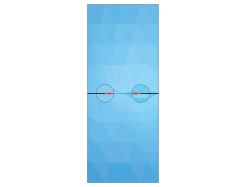

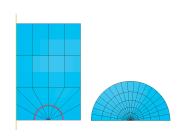

case of the full-model seam crack, left and right contour integrals are

defined in

Abaqus/CAE,

as shown in

Figure 3.

Either the normal to the crack extension or the q vectors

can be used to define the crack extension direction.

One advantage of using second-order elements with the conventional finite

element method is that they can be used to model the desired singularity at the

crack tip. To obtain a

singularity term, the following conditions must be met:

The elements around the crack tip must be focused on the crack tip. One

edge of each element must be collapsed to zero length (as shown in

Figure 2)

so that the nodes of this zero length edge are located at the crack tip.

The “midside” nodes of the edges radiating out from the crack tip of

each of the elements attached to the crack tip must be placed at one-quarter of

the distance from the crack tip to the other node of the edge.

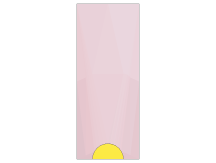

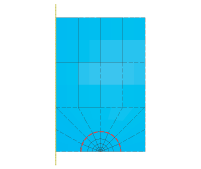

The region around the crack tip can be partitioned as shown in

Figure 4

and swept meshed with elements having a quad-dominated shape. The node

connectivity table is adjusted internally by

Abaqus/CAE

to create the degenerate quadrilateral elements.

If the coincident nodes at the crack tip are constrained to displace

together, the only singularity term in strain is ;

if the crack-tip nodes are free to displace independently, the crack-tip

singularity in strain includes a

term in addition to the

term. These methods of creating singularities in standard isoparametric

elements are explained in detail by Barsoum (1976).

The material type determines the singularity at the crack tip. A linear

elastic material exhibits a

singularity in strain at a sharp crack tip, whereas a perfectly plastic

material exhibits a

singularity in strain. The singularity in strain for a plastic hardening

material lies somewhere between

and .

Frequently the need for meshing simplicity with a preprocessor is greater

than the need for extreme accuracy of contour integral results. The contour

integral results often will be adequate as long as some singularity is

included. For example, a

singularity is introduced if the element edges are collapsed, the nodes at the

crack tip are free to displace independently, and the midside nodes are not

moved to the quarter points (they remain at the midside points). This

singularity is often quite adequate for elastic-plastic problems.

The model in this example problem uses a linear elastic material and, thus,

should be modeled with only a

singularity term.

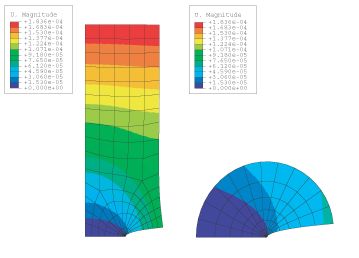

For the quarter model of the double-edged notch specimen, symmetry is used

for calculating the contour integral results. Thus, the results for the contour

integrals are multiplied by two before being output. The three-dimensional

model uses the same mesh with one layer of 20-node bricks, as shown in

Figure 5.

The loading applied is either a uniform edge load in two dimensions or a

uniform surface pressure (of negative magnitude) in three dimensions.

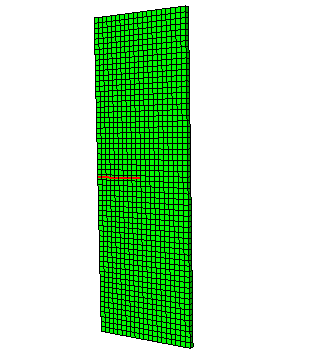

When the extended finite element method is used, the mesh is not required to

match the cracked geometry. The presence of a crack is ensured by the special

enriched functions in conjunction with additional degrees of freedom. This

approach also removes the requirement to explicitly define the crack front or

to specify the virtual crack extension direction when evaluating the contour

integral. The data required for the contour integral will be determined

automatically based on the level set signed distance functions at the nodes in

an element. First-order brick elements with both full integration and reduced

integration are used for this example. The mesh is shown in

Figure 6.

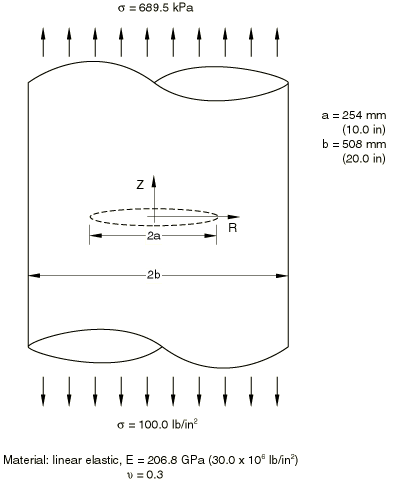

The axisymmetric model corresponds to a penny-shaped crack in a round bar.

The model is shown in

Figure 7

and is loaded in Mode I by uniform tension applied to the top and bottom

surfaces. Symmetry about r = 0 and z

= 0 allows you to model only the top right-hand quadrant with a mesh, as shown

in

Figure 8.

Second-order elements (CAX8 and CAX8R) are used.

The third example is a single-edged notch specimen under Mode I tension, as

shown in

Figure 9.

This specimen contains a crack in the symmetry plane in a homogeneous linear

elastic material. This example has been studied using both the conventional

finite element method and the extended finite element method. Due to symmetry

only the top half-plane is modeled for the specimen when used with the

conventional finite element method. The complete body is modeled when used with

the extended finite element method. Second-order elements CPE8 and CPS8 are used with the conventional finite element method, while

first-order brick elements C3D8 and first-order tetrahedral elements C3D4 are used with the extended finite element method.

The last example is also a single-edged notch specimen under Mode I tension,

as shown in

Figure 9.

This specimen contains a crack lying along the interface between two dissimilar

elastic materials. The complete body is modeled for the specimen with an

interface crack. Second-order elements CPE8 and CPS8 are used for this example.

The J-integral, stress intensity factors, and

T-stress should be path independent, and

Abaqus

provides for its evaluation on as many contours as you request. The first

contour is normally at the crack tip, and subsequent contours are generated

automatically as contours passing through the nearest neighboring elements,

moving out from the crack tip. The mesh used in this case has several rings of

elements surrounding the crack tip and as many contours as the number of rings

that can be requested. The contour integral should be path independent, so the

variation of values between contours can be taken as an indicator of the

quality of the mesh for determining the fracture parameters. Path independence

of the contour integral values is sufficient to indicate mesh convergence for

stress, strain, or displacements.