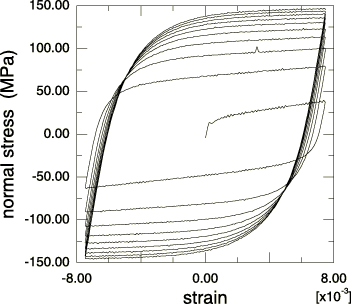

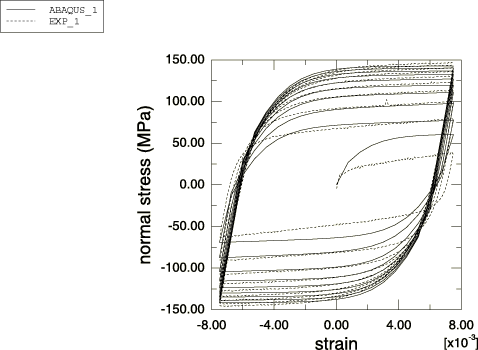

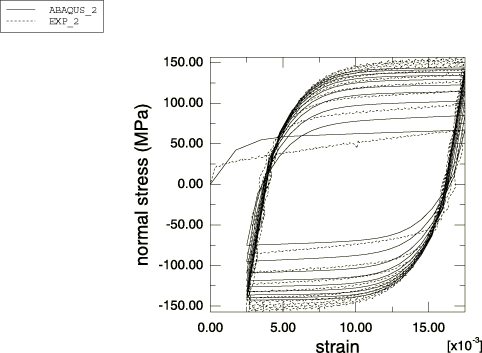

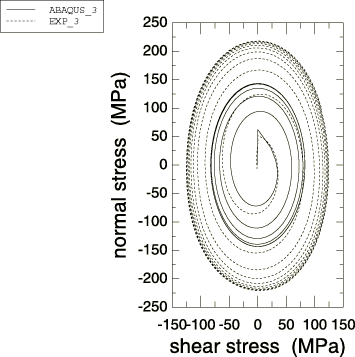

The model is calibrated using test data from a uniaxial experiment (Figure 1) obtained at a strain range 1.5%. Both the kinematic component and isotropic hardening component of the model are calibrated.

The shape of the first cycle differs from the shape of subsequent cycles, suggesting that the kinematic hardening component is a function of the cycle number. Since the model does not allow for such a dependency, a representative shape must be chosen. The objective in this example is to compare the model predictions with test data over many cycles. The stabilized cycle is, therefore, chosen for calibration. If the model were being used to simulate only one or two load cycles, it would be more appropriate to use the first loading cycle for calibration.

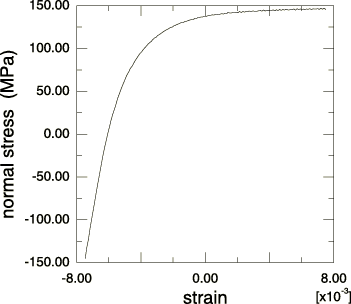

The second half of the saturated cycle used for calibrating the kinematic hardening material parameters C and is shown in Figure 2. The data are entered as values of yield stress, , versus plastic strain, , to define the stabilized cycle of the metal plasticity model, where

with the total strain for data point i, and The onset of yield is taken as 46.9 MPa. The calibration yields 33.55 GPa and 701.3; these quantities are output to the printed output (.dat) file using a model definition data request.

The isotropic hardening component is calibrated next. Isotropic hardening defines the evolution of the elastic range as a function of equivalent plastic strain. The size of the elastic range can be determined easily at points where the loading is reversed as half the difference between the yield stress in tension and compression. For the stabilized cycle the size of the elastic range is 96.2 MPa. The corresponding values of equivalent plastic strain are obtained by assuming that the test is approximately performed as a symmetric plastic strain-controlled experiment, where

and is an averaged yield stress over all the cycles. is taken as 75.0 MPa for this material. With this assumption the equivalent plastic strain is obtained as

where i is the cycle number. This approximation yields a value of 25.16% for the last cycle ( 10). The resulting data are used to define the size of the elastic range. The change in elastic range during the first half-cycle is specified as zero to compensate for the difference in the shape of this cycle compared to subsequent cycles.