The ALE Adaptive Mesh Sweeping Algorithm

Adaptive mesh smoothing is performed after the structural equilibrium equations have converged. The mesh smoothing equations are solved explicitly by sweeping iteratively over the adaptive mesh domain. During each mesh sweep, nodes in the domain are relocated—based on the positions of neighboring nodes obtained during the previous mesh sweep—to reduce element distortion. The new position, , of a node is obtained as

where is the original position of the node, is the nodal displacement, are the neighboring nodal positions obtained during the previous mesh sweep, and are weight functions obtained from one or a weighted mixture of the following methods. The displacements applied during sweeps are not associated with mechanical behavior.

Original Configuration Projection

Original configuration projection is the default in Abaqus/Standard and determines the weight function from a least squares minimization procedure that minimizes node displacement in a projection of the mesh back to the original configuration. This method of smoothing affects only deformations of the mesh and not the original mesh.

Volume Smoothing

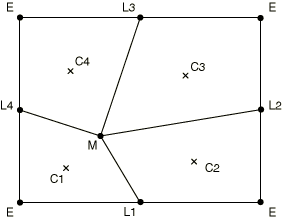

Volume smoothing determines the weight function by computing a volume-weighted average of the element centers in the elements surrounding the node. In Figure 1 the new position of node M is determined by a volume-weighted average of the positions of the element centers, C, of the four surrounding elements. The volume weighting will tend to push the node away from element center C1 and toward element center C3, thus reducing element distortion.

Volume smoothing is supported in structured domains, where every node is surrounded by four elements in two dimensions or eight elements in three dimensions.

Combining Smoothing Methods

The default smoothing method in Abaqus/Standard is original configuration projection. To choose an alternate smoothing method or to combine the smoothing methods, you specify the weighting factor for each method. When more than one smoothing method is used, a node is relocated by computing a weighted average of the locations predicted by each chosen method. All weights must be zero or positive, and their sum must be nonzero. The weights are significant only in a relative sense; their values are normalized so that their sum is 1.0.

Input File Usage

ADAPTIVE MESH CONTROLS, NAME=name original configuration projection weight, volume smoothing weight

For example, the following option could be used to define an equal blend of original configuration projection and volume smoothing:

ADAPTIVE MESH CONTROLS, NAME=name 0.5, 0.5

Abaqus/CAE Usage

Step module: : Name: name, Original configuration projection: original configuration projection weight, Volumetric: volume smoothing weight

Geometric Enhancements to the Basic Smoothing Methods

The conventional forms of the basic smoothing methods might not perform well in highly distorted domains. You can use geometrically enhanced forms of the basic smoothing algorithms as a technique to mitigate distortion. These forms are heuristic and based on nodal locations only. Due to their heuristic nature, geometric enhancements might not always improve the mesh smoothing.

Input File Usage

Use the following option to apply geometric enhancements to the smoothing algorithm:

ADAPTIVE MESH CONTROLS, NAME=name, GEOMETRIC ENHANCEMENT=YES

Abaqus/CAE Usage

Step module: : Name: name, toggle on Use enhanced algorithm based on evolving element geometry

Application of the Sweeping Algorithm

The mesh smoothing process begins with the mesh in its current displaced equilibrium configuration. Nodes that have no displacement degrees of freedom, such as those connected to acoustic elements, are maintained at their most recent configuration. Mesh smoothing is then driven by distortions in the current configuration and by boundary constraints. These boundary constraints can be described directly through adaptive mesh constraints. In the case of structural-acoustic boundaries the structural mesh boundary provides a constraint that controls the smoothing of adjacent acoustic element regions.

When these boundary constraints are much larger than the characteristic element length in the adaptive mesh domain, significant geometric changes, such as the development of corners, can occur. To prevent such changes, the constraints are applied gradually over a series of “subincrements” onto the domain boundary. The number of subincrements used is determined on the basis of the magnitude of the maximum surface displacement and the characteristic element dimension.

The remaining nodes (nodes not driven by constraints) are identified as interior nodes, free surface nodes, edge nodes, or corner nodes. These nodes are treated as described in Defining ALE Adaptive Mesh Domains in Abaqus/Standard.

At the end of mesh sweeping the new geometry is checked to ensure that elements did not become severely distorted during mesh smoothing. Abaqus/Standard responds to severe distortion in different ways, depending on the elements and procedures used. When adaptive meshing is used with acoustic elements, the current analysis increment is repeated with a reduced time increment, followed by another adaptive mesh smoothing attempt. When adaptive meshing is used with other elements, severe distortion results in abandonment of mesh smoothing for that increment. In cases where adaptive mesh constraints are also defined, Abaqus/Standard exits since the constraints cannot be satisfied.

Controlling the Frequency of ALE Adaptive Mesh Smoothing

In most cases the frequency of adaptive meshing is the parameter that most affects the mesh quality. By default, mesh smoothing will be performed after each converged structural analysis increment. You can change the frequency of adaptive meshing, except when spatial adaptive mesh constraints are defined.

Input File Usage

ADAPTIVE MESH, FREQUENCY=number of increments

Abaqus/CAE Usage

Step module: : toggle on Use the adaptive mesh domain below, Frequency: number of increments

Controlling Convergence of ALE Adaptive Mesh Smoothing

The adaptive mesh smoothing equations are solved explicitly by sweeping iteratively over the adaptive mesh domain. During each mesh sweep, nodes in the domain are relocated based on the current positions of neighboring nodes to reduce element distortion.

Mesh smoothing is performed following the end of a converged increment. You can control the intensity of the mesh smoothing by defining the number of mesh sweeps required. When the displacements are large, more iterations are usually required. When used in acoustic analyses, more iterations are usually required when the volume of the elements in the acoustic domain decreases compared to the case when the volume increases during structural loading.

You can specify the number of mesh sweeps to be performed in each adaptive mesh increment. The default number of mesh sweeps is one.

By applying the mesh sweeping algorithm repeatedly, the mesh will converge; in other words, nodal positions are obtained that do not change with further mesh sweeping. However, it is usually not necessary to apply mesh smoothing until a converged mesh is obtained; the main objective is to reduce element distortion.

Input File Usage

ADAPTIVE MESH, MESH SWEEPS=number of sweeps

Abaqus/CAE Usage

Step module: : toggle on Use the adaptive mesh domain below, Remeshing sweeps per increment: number of sweeps