Curing processes in polymers | ||

| ||

Products Abaqus/Standard

The curing process can play an important role in the use of thermosetting polymers, such as adhesives. The curing process is usually activated at elevated high temperatures, which initiate the cross-linking process in the polymer. The process is exothermic (heat is generated as the curing reaction progresses), and permanent shrinkage strains develop due to the formation of chemical bonds. The thermal and shrinkage strains that develop during the process result in residual stresses that can be detrimental to the adherents or induce warpage and deformation in bonded assemblies. Therefore, it is important that the shrinkage and residual stresses can be predicted correctly.

The cure modeling capabilities have been available in Abaqus/Standard since the Abaqus 2021 FD06 (FP.2116) release as a special-purpose material modeling capability based on built-in user-defined material options (see Modeling the Cure Process in Thermosetting Polymers). A more integrated version of these capabilities is now available in Abaqus/Standard with new dedicated options and output variables that facilitate the definition of the cure model and the analysis of the results. In addition, these new cure modeling capabilities are supported with a wider range of procedures (such as heat transfer) and for more Abaqus element types.

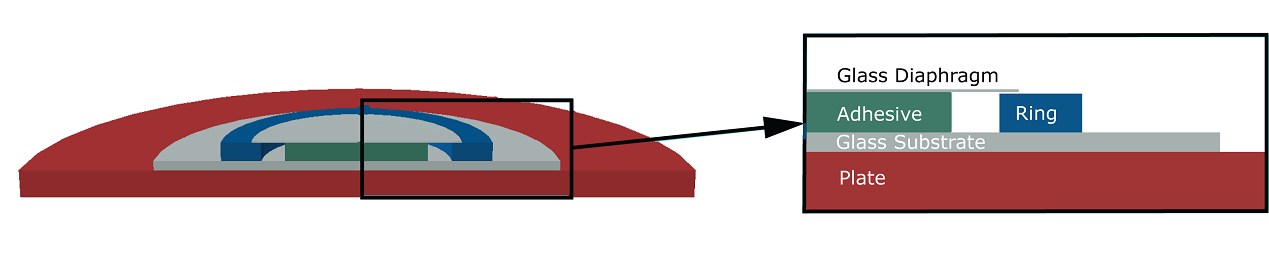

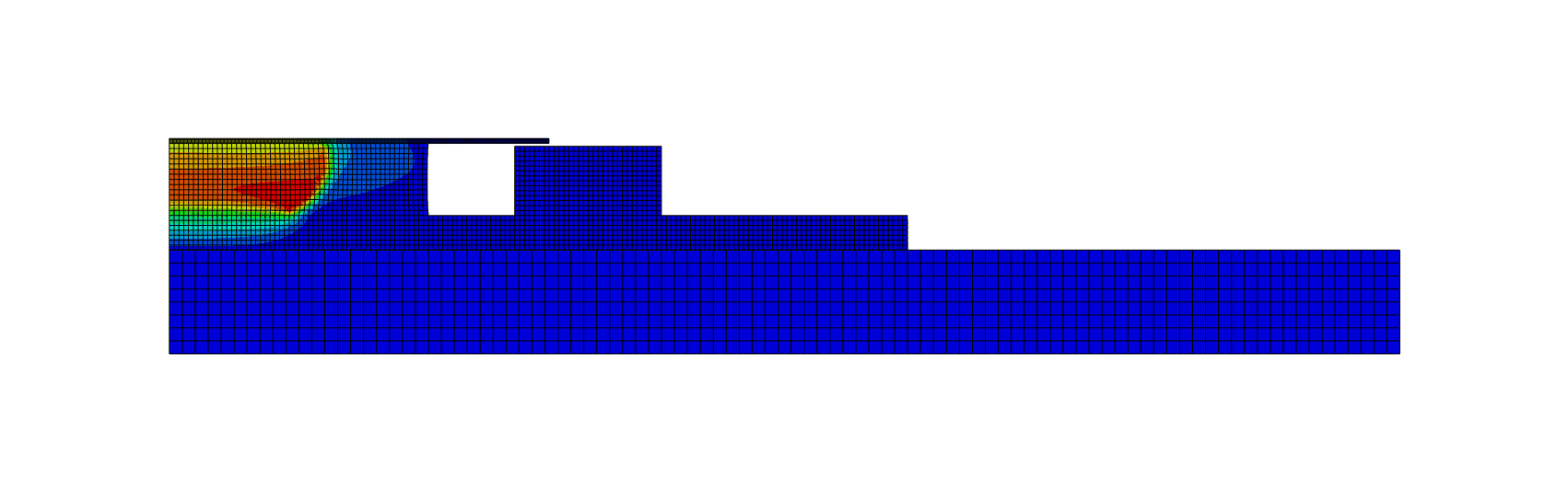

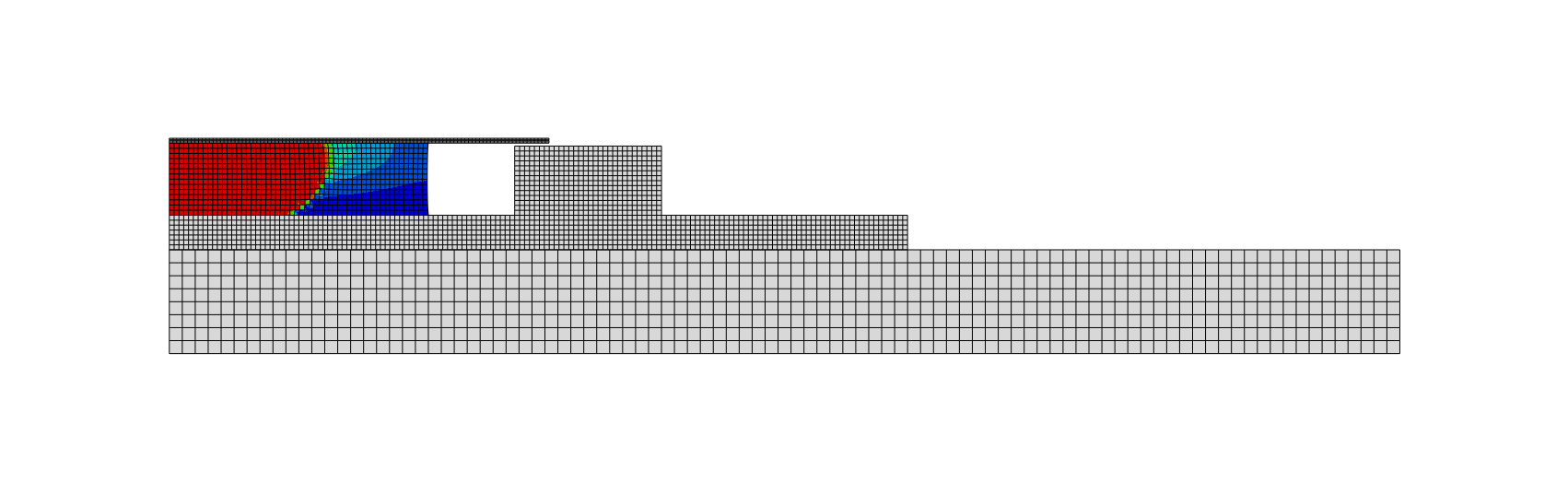

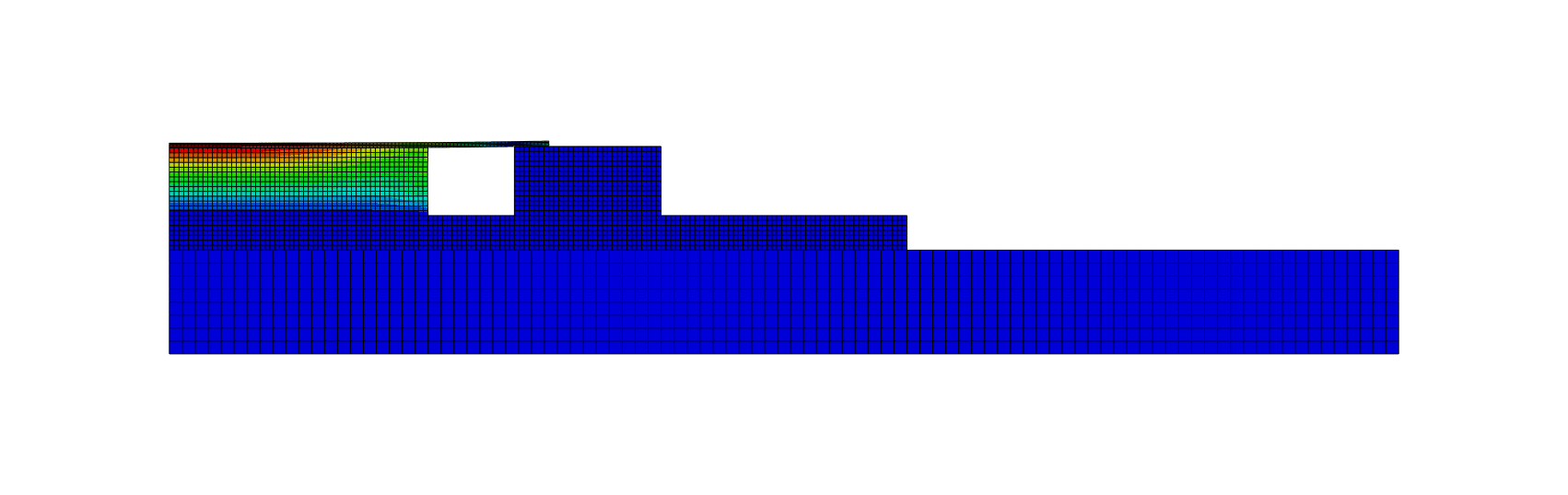

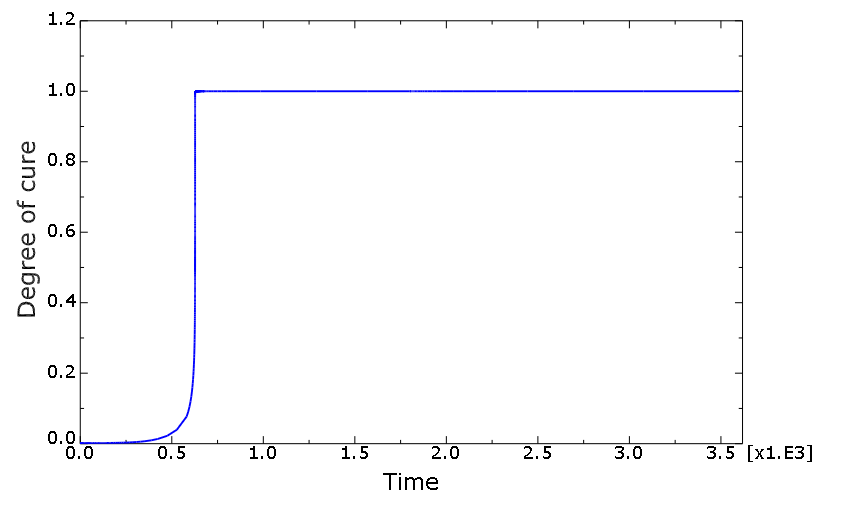

Figure 1 shows an example (courtesy of 3M Company) of the cure modeling capabilities applied to the Watts’ shrinkage test sample (Watts and Cash, 1991). A disc-shaped adhesive specimen placed between two glass plates is subjected to curing followed by cooling. Figure 2 and Figure 3 show the temperature and the degree of cure (that is, conversion) distributions in the specimen during the curing process. The deflection in the specimen after cooling due to the shrinkage strains is depicted in Figure 4. Figure 5 shows the evolution of the degree of cure at a sample point within the adhesive. Initially, the value of the conversion increases slowly and then progresses rapidly once a critical temperature is reached at the location. The elastic modulus and other mechanical properties evolve as a function of this conversion history.

Abaqus Keywords Guide

Abaqus Materials Guide

Abaqus Verification Guide

Other

-

- “Determination of Polymerization Shrinkage Kinetics in Visible-light-cured Materials: Methods Development,” Dental Materials, vol. 6, pp. 281–287, 1991.