Elements tested

C3D8R

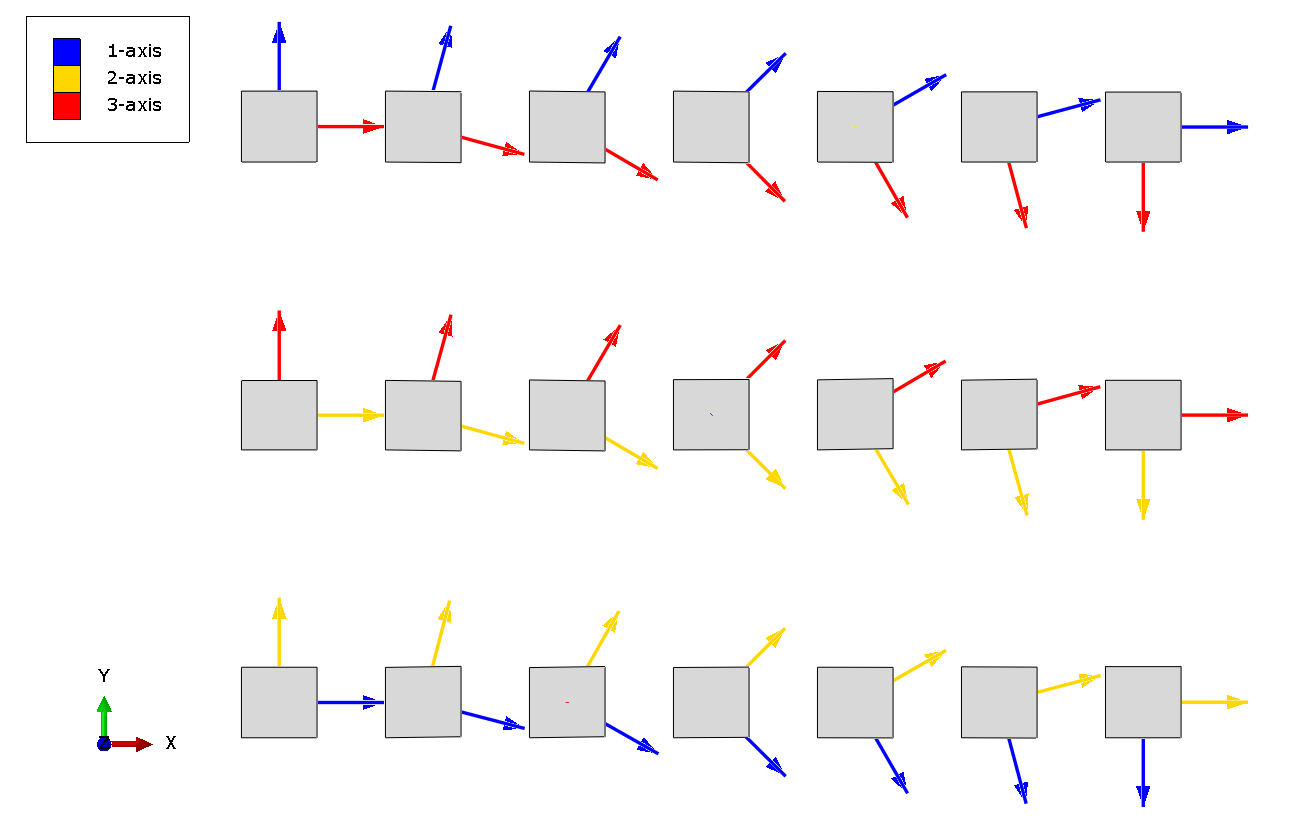

ProductsAbaqus/Explicit Elements testedC3D8R Features testedClassical metal plasticity model with Barlat yield surfaces. Problem descriptionThis verification test contains a set of single-element models subject to uniaxial tension for various off-axis angles between the material directions and the loading direction. The test is designed to verify the yield stress ratios and strain ratios (Lankford's r-values) obtained in the simulations against the analytical solutions.

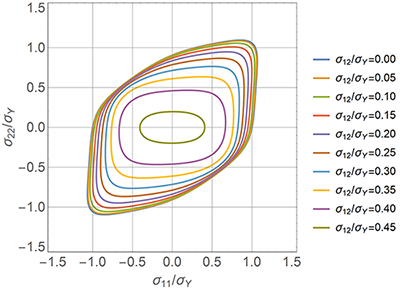

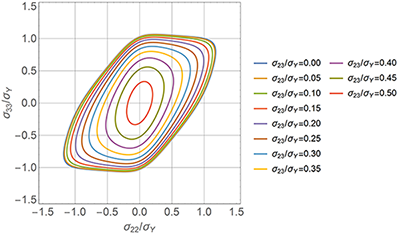

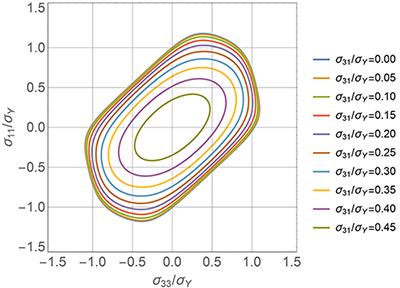

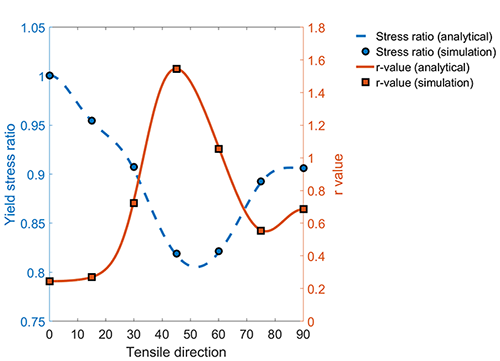

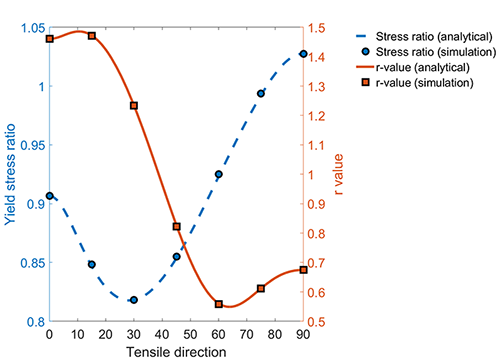

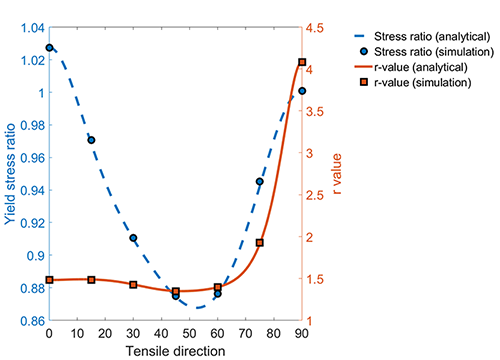

Results and discussionThe yield stress ratio is defined as where is the stress in the loading direction that can be obtained as output variable S11 in the global frame and is the reference yield stress that can be obtained as output variable YIELDPOT. The strain ratio (Lankford's r-value) is defined as where and are the plastic strains in the width and thickness directions, respectively, corresponding to output variables PE22 and PE33 in the global frame. The results of the yield stress and strain ratios agree well with the analytical solutions for the four materials. Comparisons of the simulation results and analytical solutions for the material 2090-T3 with loading applied on three material planes are shown in Figure 5, Figure 6, and Figure 7. The yield stress ratio and strain ratio of the Mises plasticity are always one. The models with equivalent definitions of the Mises yield surface also match the analytical solutions. Input files

References

Tables

Figures       | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||