Prescribe boundary conditions

-

In the

Model Tree,

double-click the BCs container to prescribe boundary

conditions on the model. In the Create Boundary Condition

dialog box that appears, name the boundary condition

Fix left end, and selectLugLoadas the step in which it will be applied (since it is a fixed condition, it can be applied either in the initial step or the analysis step; here we choose the analysis step for convenience). Accept Mechanical as the category andSymmetry/Antisymmetry/Encastreas the type. Click Continue. -

You may need to rotate the view to facilitate your selection in the

following steps. Select

ViewRotate

from the main menu bar (or use the

tool from the

View Manipulation toolbar)

and drag the cursor over the virtual trackball in the viewport. The view

rotates interactively; try dragging the cursor inside and outside the virtual

trackball to see the difference in behavior. Click mouse button 2 to exit the

rotate view tool before proceeding.

tool from the

View Manipulation toolbar)

and drag the cursor over the virtual trackball in the viewport. The view

rotates interactively; try dragging the cursor inside and outside the virtual

trackball to see the difference in behavior. Click mouse button 2 to exit the

rotate view tool before proceeding.

-

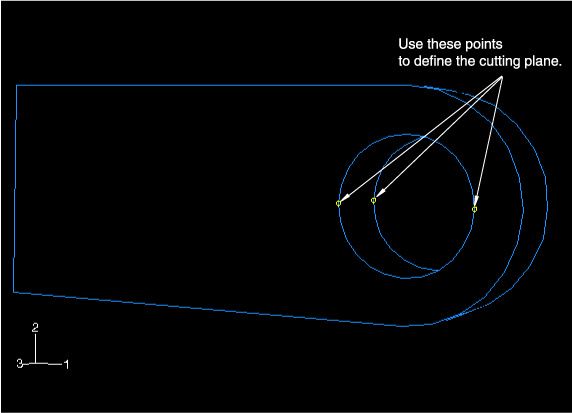

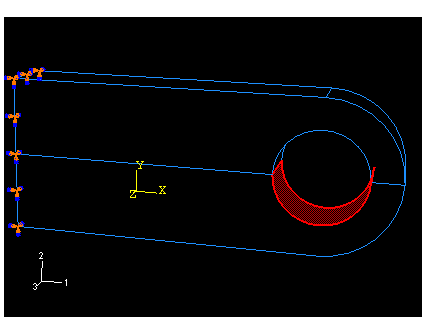

Select the left end of the lug (indicated in

Figure 1)

using the cursor. Click Done in the prompt area when the

appropriate region is highlighted in the viewport, and toggle on

ENCASTRE in the Edit Boundary

Condition dialog box that appears. Click OK

to apply the boundary condition.

Arrows appear on the face indicating the constrained degrees of freedom. The encastre boundary condition constrains all active structural degrees of freedom in the region specified; after the part is meshed and the job is created, this constraint will be applied to all the nodes that occupy the region.

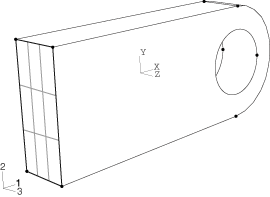

to divide the part in half. Use the

to divide the part in half. Use the