Geometry and model

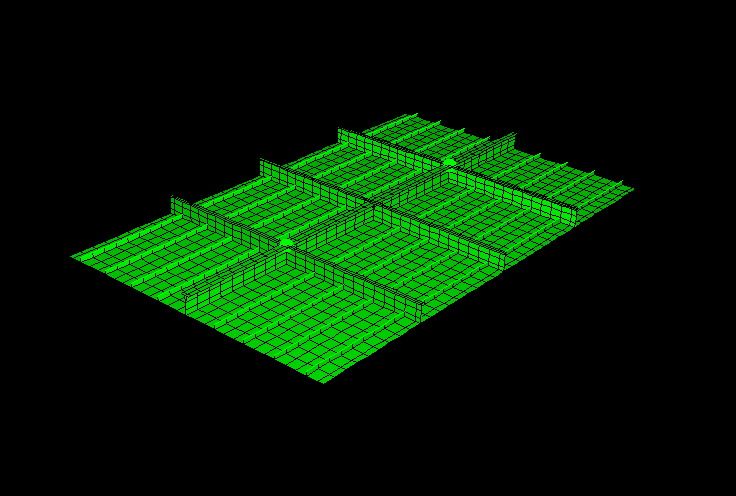

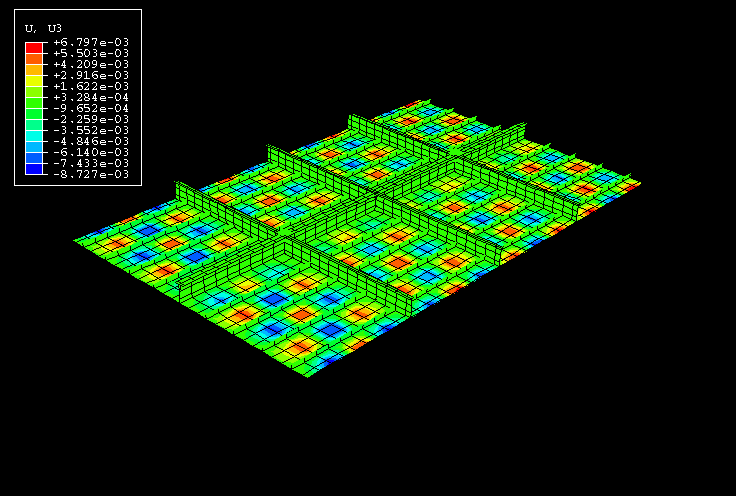

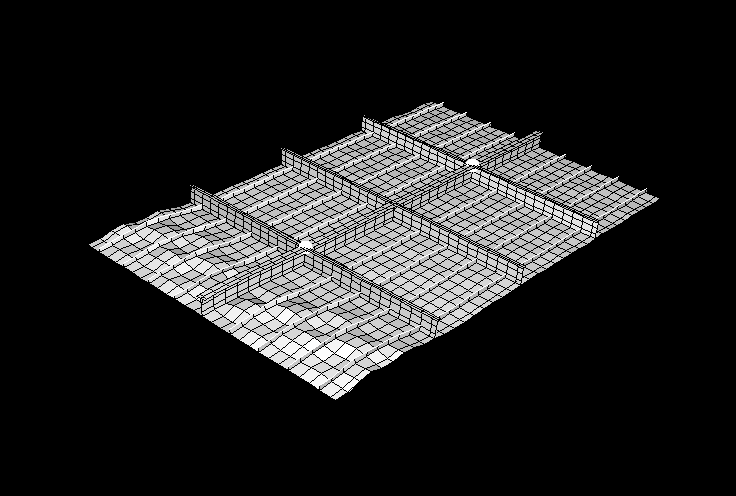

The model consists of a rectangular plate 10.8 m (425.0 in) long, 6.75 m (265.75 in) wide, and 5.0 mm (0.2 in) thick. This plate has several reinforcements in both the longitudinal and transverse directions (Figure 1). The plate represents part of a larger structure: the two longitudinal sides have symmetry boundary conditions, and the two transverse sides have pinned boundary conditions. In addition, springs at two major reinforcement intersections represent flexible connections to the rest of the structure. The mesh consists of S4 shell elements for both the plate and larger reinforcements and additional S3 shell and B31 beam elements for the remaining reinforcements. The entire structure is made of the same construction steel, with an initial flow stress of 235.0 MPa (34.0 ksi).

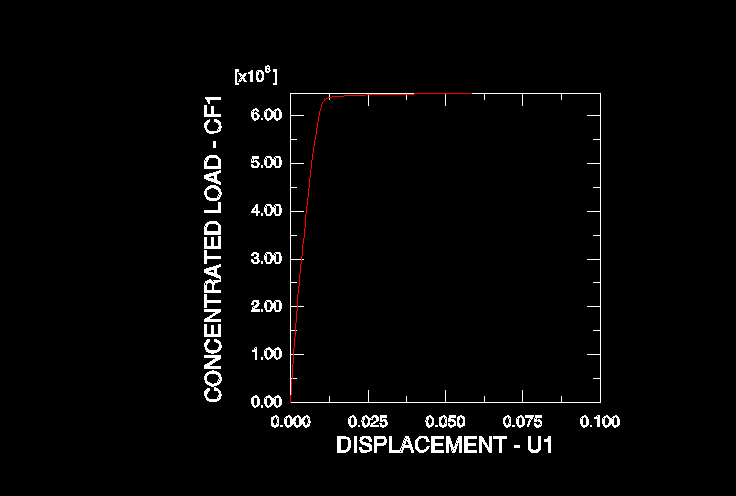

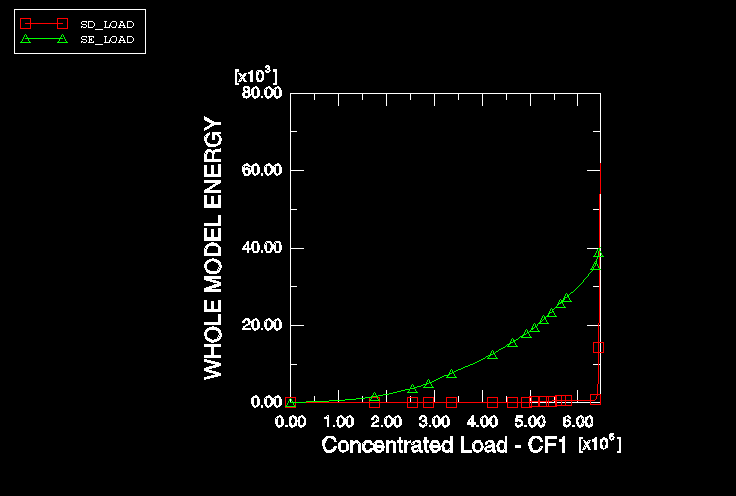

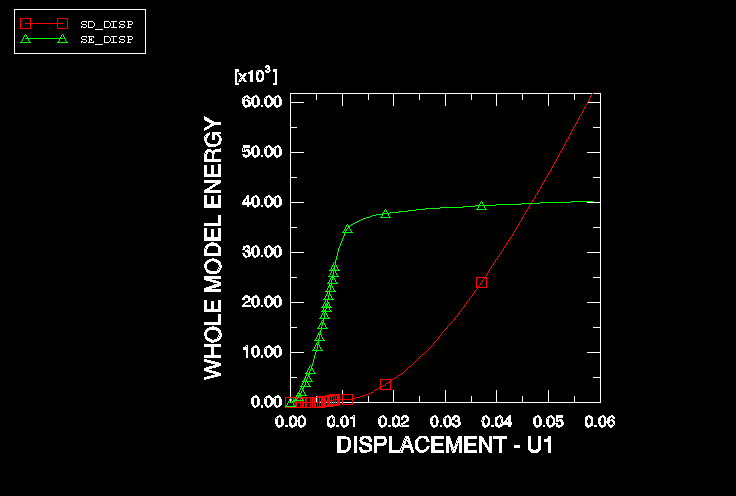

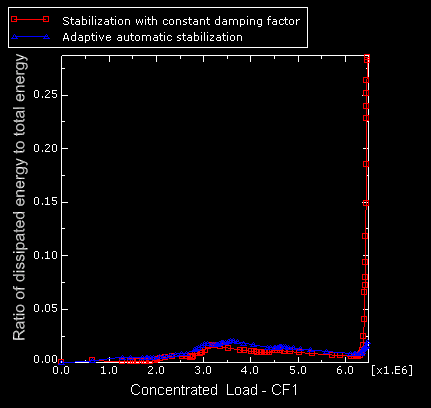

To provide stability to the numerical solution upon the anticipated buckling, automatic stabilization based on volume proportional damping is added to the model. Two forms of automatic stabilization are considered: one with a constant damping factor that is chosen by default (see Automatic Stabilization of Static Problems with a Constant Damping Factor), and one with an adaptive damping factor (see Adaptive Automatic Stabilization Scheme).