Application description

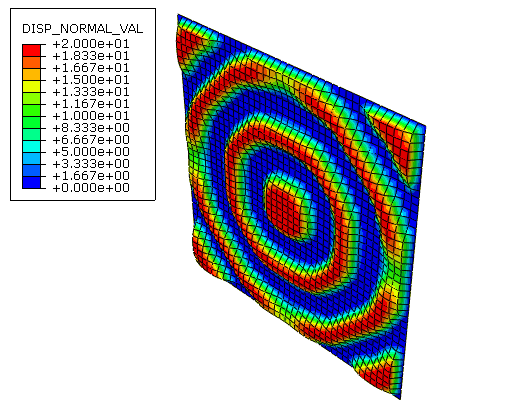

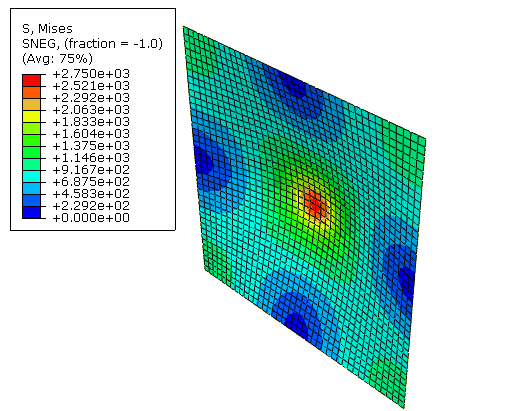

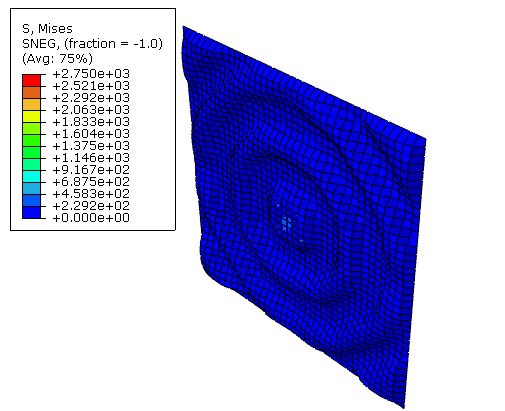

This example illustrates condition-based bead optimization of a simply supported plate. During a bead optimization, the nodes of the shell elements are moved in the direction of the shell normal to increase the moment of inertia, which leads to a greater stiffness or higher eigenfrequencies. The resulting beads are easy to reproduce in a sheet metal stamping process without increasing the mass or cost of the finished product. For more information, see Bead Optimization.

Geometry

The plate is a 600 mm × 600 mm three-dimensional shell part. A shell section is assigned to the part with a thickness of 1.5 mm. The shell section uses the default Simpson integral rule with five integration points through the shell section.

Materials

The plate is made of an elastic material with a Young's modulus of 210 GPa and a Poisson’s ratio of 0.3.

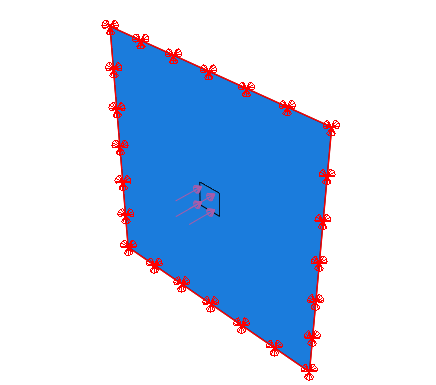

Boundary conditions and loading

The edges of the plate are fixed in all three translation degrees of freedom. A pressure of 1.0 is applied to a partitioned region at the center of the plate, as shown in Figure 1.

Optimization features

The bead optimization is configured as described in the following sections.

Optimization task

This example creates a bead optimization task that is governed by the condition-based optimization algorithm. The bead width is specified as 60 mm.

Design area

The entire plate is selected as the design area. By default, the Optimization module freezes the position of the nodes around the edge of the plate that were included in the boundary condition.

Design responses

A design response is created that calculates the maximum of the strain energy over all the elements in the design area. A second design response calculates the bead height.

Objective function

A single objective function attempts to minimize the maximum of the strain energy of the design area. Since compliance is defined as the sum of the strain energy, and stiffness is the reciprocal of compliance, the objective function is equivalent to maximizing the stiffness of the plate.

Constraint

A single constraint sets the bead height to 20 mm.