The geometry and material of the disc are identical to those described

earlier except that the inner surface of the disc is not totally constrained,

as it is for the static problem. Instead, all the nodes on the inner surface

are attached to a node (axle node) located at the center of the disc using

kinematic coupling constraints. This facilitates the application of angular

velocity or displacement to the axle node to simulate rolling in the Lagrangian

approach, as well as the measurement of reaction forces and moments at the

axle. The mesh is more refined for the rolling problem compared to the static

problem. In particular, two elements are used through the thickness of the

disc. The first step is a do-nothing step to facilitate import of the initial

state from

Abaqus/Standard

to

Abaqus/Explicit.

This step is followed by a static step in which the rigid surface is pushed

against the disc a distance of 0.15 inches. The next step involves rolling of

the loaded disc against the rigid surface, which is accomplished in two ways.

The first is a Lagrangian analysis in which an angular velocity of 2.5 radians

per second is applied to the axle node of the disc. In this example the

structure reaches a steady state after one full revolution. No additional

damage occurs in subsequent revolution cycles. Therefore, the total time is

chosen such that the disc undergoes two revolutions. A variation of the

Lagrangian analysis includes modeling of permanent set using a metal plasticity

material definition. In the second analysis the rolling is simulated using the

steady-state transport capability in

Abaqus/Standard.

Frictional and inertial effects are neglected in both cases.

The steady-state transport capability directly obtains the steady-state

rolling solution of the disc on the rigid surface. Due to Mullins effect the

stress state for the rolling solution can be quite different from the stress

state for the static non-rolling solution. As a result, an attempt to obtain a

steady-state rolling solution directly from a static non-rolling solution may

lead to convergence problems in the Newton's scheme that is used to solve the

overall nonlinear system of equations. Since the damage and, hence, the

discontinuity in state are independent of the angular rolling speed, a time

increment cutback during the steady-state transport step does not overcome the

convergence difficulties. Such convergence difficulties can be resolved by

introducing the damage gradually over an additional steady-state transport step

preceding the actual analysis. In this example this is accomplished by

following the static loading step with a steady-state transport step with a

small rolling angular speed of 0.25 radians per second and with the Mullins

effect ramped up over the time period of the step. This step is followed by

another steady-state transport step at an angular speed of 2.5 radians per

second with the MULLINS parameter set equal to STEP, which provides the solution we are interested in obtaining.

A Lagrangian simulation is also carried out in

Abaqus/Explicit.

The kinetic energy is monitored to ensure that the problem remains essentially

quasi-static. The revolutions of the disc are carried out by applying a

rotational displacement (corresponding to two full revolutions) at the axle

node using an amplitude with a smooth step definition to reduce the noise in

the response. The compressibility parameter, ,

is chosen to be 5 × 10

−5, an order of magnitude higher than the actual value, to obtain

relatively higher time increments and, thus, a relatively lower run time.

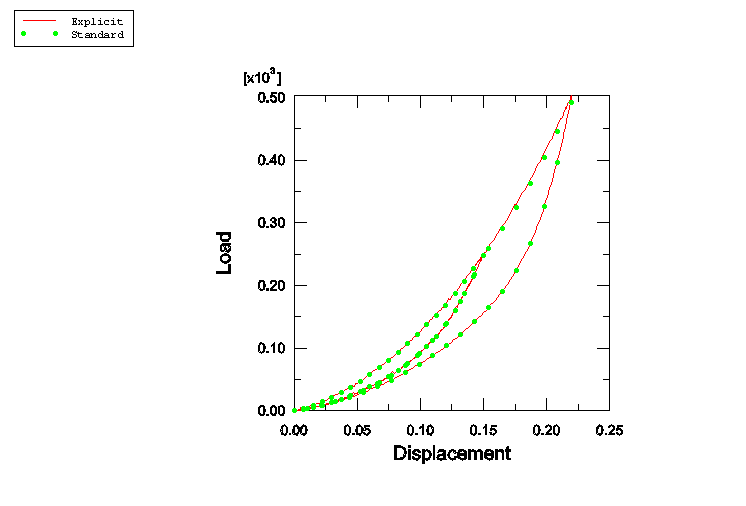

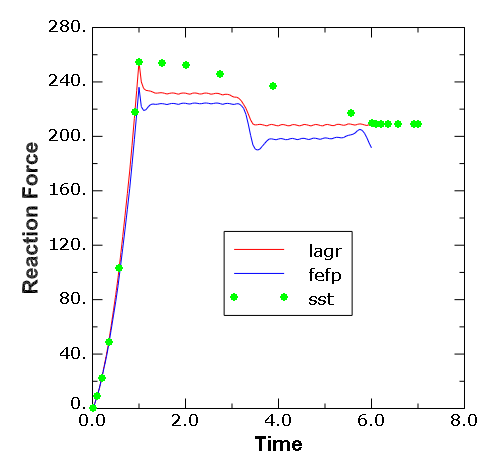

Figure 5

compares the time history of the reaction force at the axle node for the

Lagrangian and the steady-state rolling analyses in

Abaqus/Standard.

The results for the Lagrangian problem without permanent set (curve labeled

lagr) indicate that the reaction force increases during

the loading step and decreases during the first revolution of the disc. The

decrease in the reaction force is a result of lower overall stresses due to

damage in the material. During the second revolution of the disc the reaction

force remains constant as no additional damage occurs. The results of the

Lagrangian problem including permanent set (curve labeled

fefp) show a softer behavior compared to the former

problem and clearly indicate the presence of permanent set in the footprint

area as the solid disc rolls against the rigid surface. The steady-state

rolling results (labeled sst) show a gradual transition of

the reaction force during the first steady-state transport step that ramps up

the Mullins effect. During the second steady-state transport step the reaction

force remains constant at the value reached at the end of the prior step. This

curve also illustrates that the damage associated with the Mullins effect is

independent of the angular speed of rotation. The reaction force remains the

same at angular speeds of both 0.25 and 2.5 radians per second. If the Mullins

effect is not applied gradually over the first steady-state transport step, the

discontinuity between the rolling and the static states may lead to convergence

difficulties.

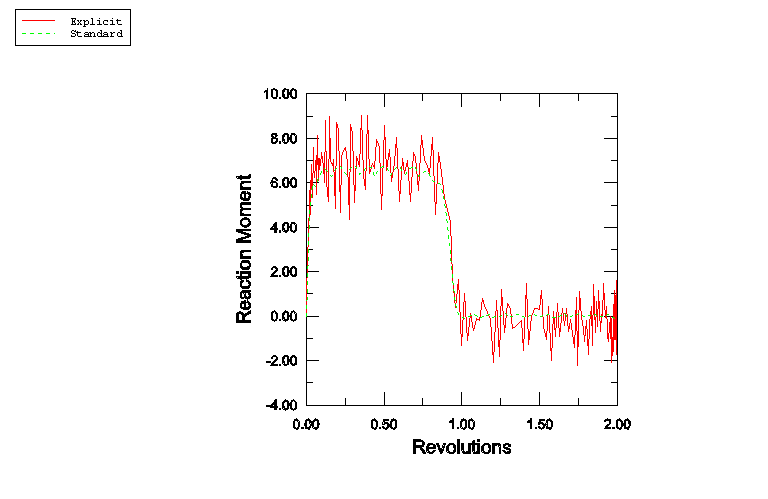

The same results can be observed from a different viewpoint in

Figure 6,

which shows the reaction force as a function of the number of revolutions for

both

Abaqus/Standard

and

Abaqus/Explicit.

The reaction force decreases during the first revolution and remains steady

(except for the noise in the

Abaqus/Explicit

analysis) during the second revolution.

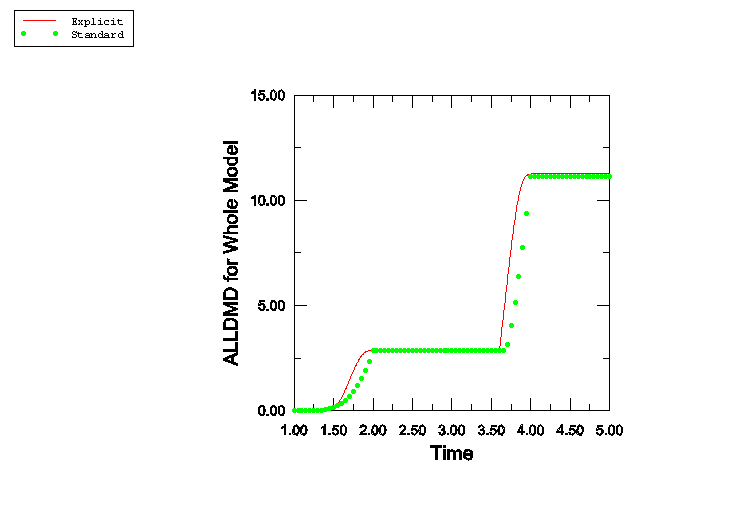

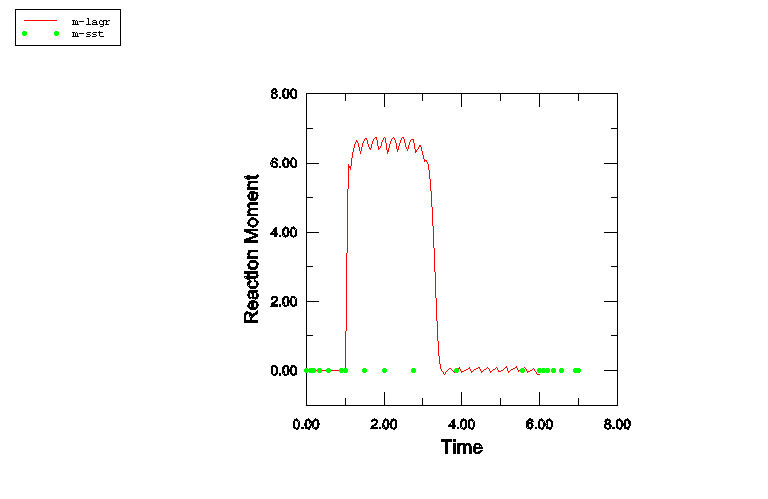

Figure 7

shows a comparison of the time histories of the reaction moment at the axle

node between the Lagrangian and the steady-state rolling solutions. The

Lagrangian results are labeled m-lagr, while the

steady-state rolling results are labeled m-sst. If the

material were purely hyperelastic (without damage), the contact forces would be

symmetric about a plane normal to the rigid surface and containing the axle;

hence, no torque would be required to rotate the disc. However, as a result of

the damage associated with Mullins effect, the contact forces are not

symmetrical because material particles transition through the contact area

during the very first revolution. This leads to the reaction moment during the

first revolution, as shown in the results for the Lagrangian analysis. The

moment reduces to zero during the second revolution. The steady-state rolling

results do not include the transient solution of the first revolution; hence,

they show a zero moment at all times.

Figure 8

shows the same results from a different viewpoint. In this figure the reaction

moment is plotted as a function of the number of revolutions for both

Abaqus/Standard

and

Abaqus/Explicit.

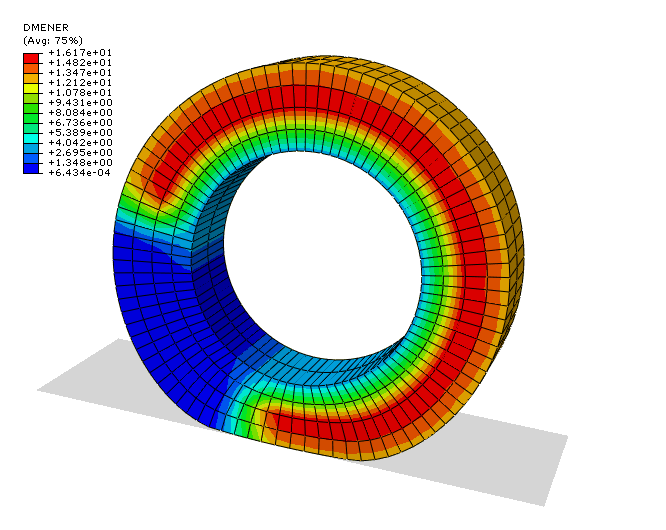

Figure 9

shows a contour plot of the damage energy dissipated at material points at an

instant of time that corresponds to about three-quarters of the way into the

first revolution of the disc. The figure indicates damage in the material that

has already passed through the contact area and no damage in the material that

is yet to pass through the contact area. This corresponds to damage in about

three-quarters of the disc material. The remaining quarter is still undamaged,

as it has not undergone any deformation yet. The full disc will be damaged at

the end of the first revolution, and the damage state remains unchanged during

the second revolution.