Application description

Composite hulls are used routinely in the yacht industry. Composite materials allow manufacturers to create high-performance marine vessels that incorporate the complex hull shapes that engineers have derived from computational fluid dynamics analyses and from experimental testing. Composites also provide the strength, rigidity, and low mass that high-performance yachts require. However, incorporating many layers of material with varying orientations in a complex three-dimensional finite element model can be time consuming. The addition of local reinforcements complicates the process. These issues are described by Bosauder et al. (2006).

The composite layup capability in Abaqus/CAE simplifies the process of composites modeling by mirroring the procedure that manufacturers follow on the shop floor—stacking sheets of composite material in a region of a mold and aligning the material in a specified direction. The Abaqus/CAE composite layup editor allows you to easily add a ply, choose the region to which it is applied, specify its material properties, and define its orientation. You can also read the definition of the plies in a layup from data in a text file, which is convenient when the data are stored in a spreadsheet or are generated by a third-party tool.

Geometry

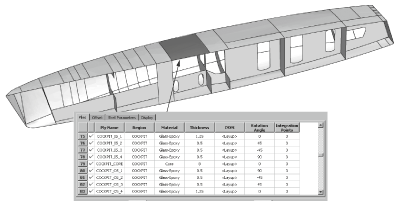

Figure 1 shows the hull, mast, rigging, and keel of the yacht model. The geometry of the model is imported as a single part from an ACIS (.sat) file, as shown in Figure 2. The part models one half of the hull, and symmetric boundary conditions are applied. The hull represents a high-performance 20-meter yacht with reinforced bulkheads that stiffen the structure. The infrastructure above the deck does not play a role in modeling the performance of the hull and is not included in the model.

Sets are created that correspond to the regions of the composite layup to which plies are applied.

Materials

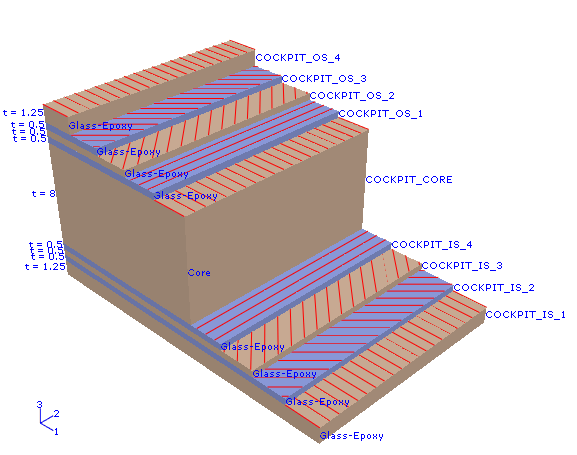

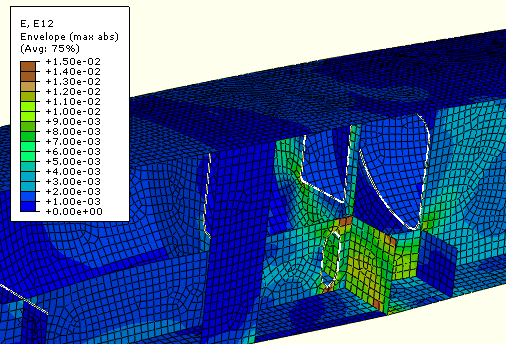

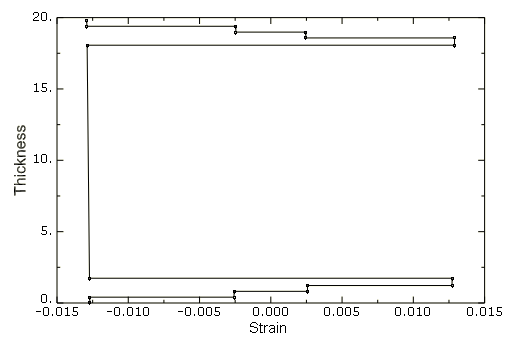

The model is partitioned into 27 regions. Each region contains plies of glass-epoxy cloth surrounding a Nomex core. Most regions contain nine plies—four glass-epoxy plies on either side of the Nomex core. However, additional plies are added to reinforce regions of high strain. Some bulkheads are reinforced with stringers made of glass-epoxy cloth with an effective Young's modulus of 128000 N/mm2. Table 1 shows the material properties of the glass-epoxy cloth, and Table 2 shows the material properties of the Nomex core.

Figure 3 shows several rows of the composite layup table and illustrates how plies and material orientations are assigned to a region of the model. Figure 4 shows a ply stack plot of the same region.

Boundary conditions and loading

The center of the model is constrained to be symmetric about the y-axis, as shown in Figure 2. The following loads are applied:

-

A hydrostatic pressure is applied to the hull. The pressure is modeled with an analytical field that increases the pressure linearly along the z-axis.

-

Concentrated forces that model the tension from the sail rigging are applied to the front, rear, and side of the deck. The forces are applied along the x-axis of a datum coordinate system. Each coordinate system has an origin at the location of the load, and the x-axis orients the load toward the location of the top of the mast. The concentrated forces are transferred to the deck through distributing couplings.

-

The load from the mast is applied at the base of the hull in the z-direction.

-

The keel is modeled with a lumped mass attached to the hull through a kinematic coupling.

-

An inertia relief load is applied at the center of the hull to bring the model into equilibrium after the loads are applied.