Problem description

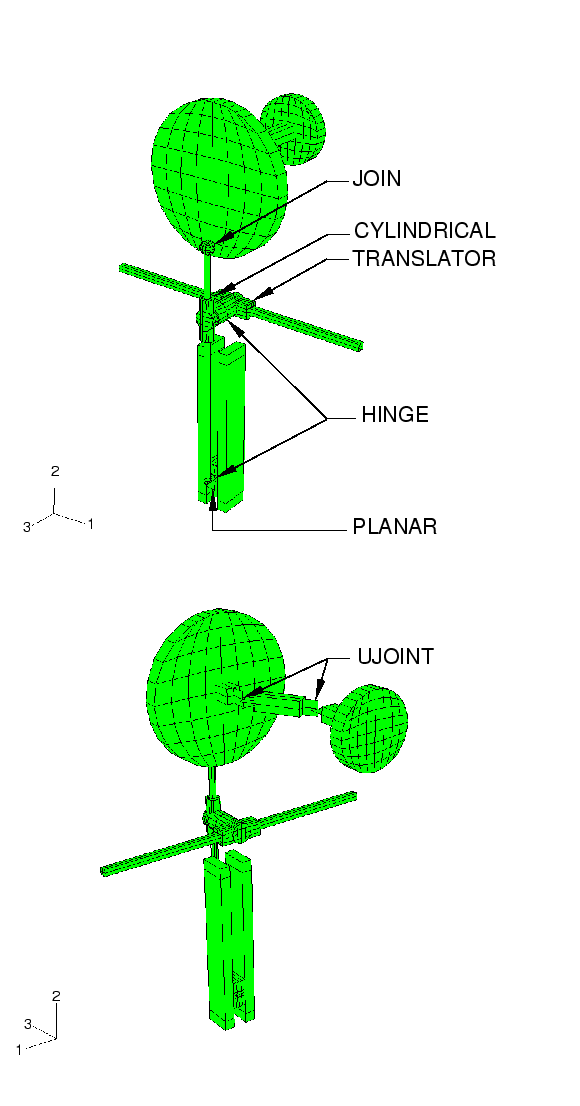

The crank mechanism considered here transmits a rotational motion through two universal joints and then converts the rotation into translational motion of two slides. The mechanism is modeled using nine rigid components attached with eight connector elements. The various kinematic constraints modeled with connector elements include TRANSLATOR, which allows relative translation along a line but no rotations; HINGE, which allows one relative rotation and fixes relative translations; CYLINDRICAL, which allows relative translation along a line and relative rotation about that line; JOIN, which fixes relative translations but leaves the rotations free; PLANAR, which keeps a point on a plane and allows only relative rotations about the normal to that plane; and UJOINT, which fixes the relative translations and enforces a universal constraint on the relative rotations. The complete model is shown in Figure 1.

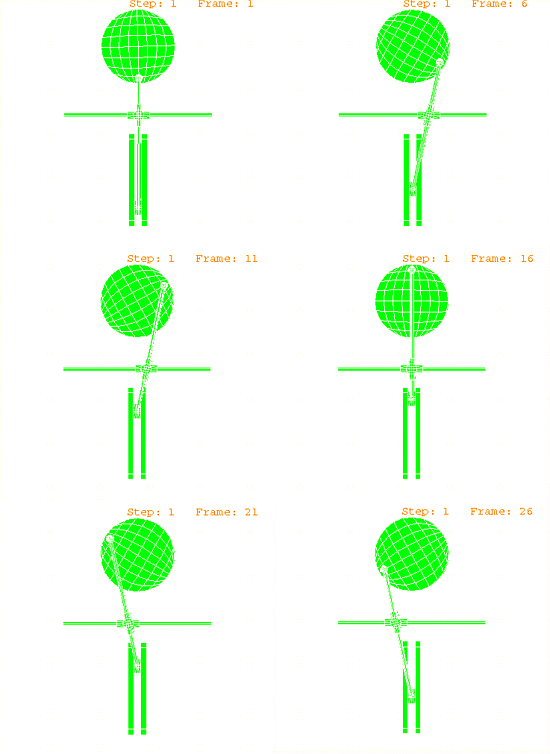

The axes of rotation of the small and large disks are parallel but offset. A constant angular velocity of the small disk is specified about its axis with a velocity boundary condition on its rigid body reference node. All other degrees of freedom of the rigid body reference node are fixed. The rotational motion of the small disk is transmitted to the large disk through two UJOINT connections and a rigid link. A UJOINT connection, or a universal rotation constraint with shared translational degrees of freedom, between two nonaligned shafts will not transmit constant angular velocity. However, two symmetrically placed universal constraints, as here, will produce constant angular velocity coupling between the two disks. The large disk is connected to a rigid circular rod with a JOIN connection. A JOIN connection is equivalent to a ball-and-socket or a spherical joint. The circular rod connects through a sleeve to a flat block. The rod and sleeve constraint is modeled with a CYLINDRICAL connection, which allows the sleeve to translate along and rotate about the rod. The attachment of the circular rod to the flat block is a HINGE connection, which allows only a single relative rotation about the shared hinge axis. The flat block, in turn, is assumed to slide between two fixed parallel plates. This sliding constraint is modeled with a PLANAR (SLIDE-PLANE and REVOLUTE) connection. The sleeve on the circular rod is connected to a square-section sleeve on the square rod with a HINGE connection. The square rod is fixed in space. The square-section sleeve slides along the square bar without rotating. This sliding constraint is modeled with a TRANSLATOR connection.

A Python script is included that reproduces the model using the Scripting Interface in Abaqus/CAE. The script imports the parts from an ACIS file and creates the constraints and connectors that define the dynamics of the mechanism. The script creates both an Abaqus/Standard and an Abaqus/Explicit model that are ready to be submitted for analysis from the Job module.

Models with frictional interactions, plasticity, and damage in connectors are created by editing the input files without friction to introduce the friction, plasticity, or damage definitions.

A model that includes sensors and actuation via user subroutine VUAMP is also included to illustrate a means to model control engineering aspects in multibody analyses. Assuming that an electric motor provides the rotational input to the system, the intent is to shut off this motor (and complete the step) as the horizontal traveling head completes one full cycle. The amplitude properties can be defined in the input file or directly within the user subroutine.