Problem description

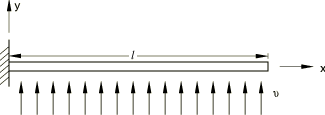

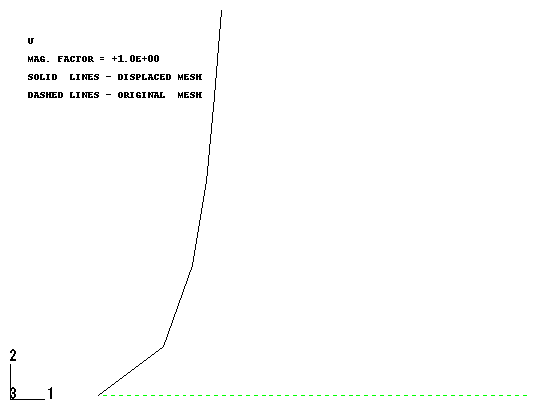

A pipe 304.8 m (1000 ft) long, initially straight and stress-free, is loaded by a uniform cross-current of 0.762 m/s (2.5 ft/sec) as shown in Figure 1. The outside radius of the pipe is 76.2 mm (0.25 ft), and its wall thickness is 15.24 mm (0.05 ft), so the pipe is “slender” and virtually inextensible (its extensional stiffness is much greater than its flexural stiffness). Abaqus provides a family of two-dimensional and three-dimensional hybrid beam elements designed specifically for use in such cases. In this case five B23H elements are used to model the pipeline.

The pipe is made of a linear elastic material, with a Young's modulus of 206.8 GPa (4.32 × 109 lb/ft2). A general beam section is used for the pipe section specification. This choice avoids numerical integration of the pipe section during the analysis and, hence, reduces computer costs. Numerical integration over the beam section would be necessary if plasticity or other material nonlinearities were to be considered.

The loading on the pipe results from a uniform current flowing in the global y-direction, as shown in Figure 1. The current velocity is 0.762 m/s (2.5 ft/s), and the density of the water is 1000 kg/m3 (1.94 slug/ft3). The transverse drag coefficient is 1.2, and the tangential drag coefficient is 0.002. The large difference between these coefficients reflects the different effects transverse and tangential flow have on the pipeline, the tangential drag being primarily a skin friction effect only. The pipeline is assumed to be built-in at one end, as shown in Figure 1.