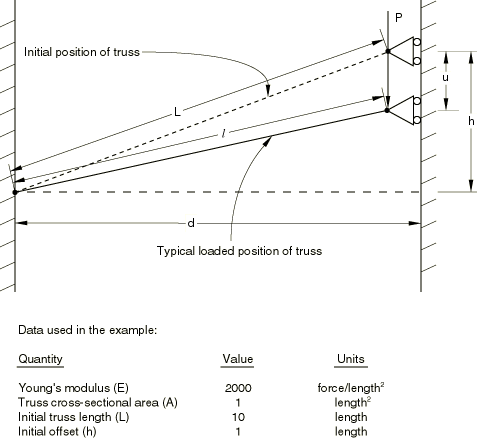

Problem description

The problem is shown in Figure 1. A uniform rod, pinned at one end and free to slide in one direction at the other, is loaded so that it is initially compressed. We assume that the response of the rod is entirely linear elastic, so the only nonlinearity arises from rotation. We also assume that the initial height of the moving end of the rod above the horizontal position, h, is small compared to the horizontal distance between the supports, d, so that the strain in the rod is small so long as

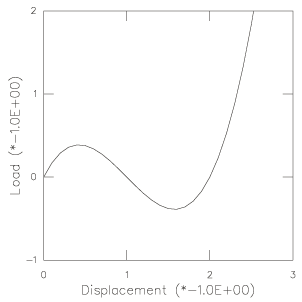

The solution clearly involves an instability, since a nonzero force is required to begin displacing the endpoint of the rod downward, but the force must drop back to zero as the rod becomes horizontal: this horizontal position is one of unstable equilibrium. Since the problem involves only one displacement variable, no bifurcation is possible, so the behavior is quite simple compared to what can happen in systems with many degrees of freedom whose response may involve instabilities. Moreover, the displacement variable is prescribed, so there are, in fact, no unknowns in this problem. To obtain a solution at regular displacement intervals, automatic time incrementation is switched off.

The structure exhibits nonlinear response throughout its deformation, unlike typical “stiff” shell-type structures that often behave in an almost linear fashion until they buckle. Therefore, this type of problem cannot be analyzed effectively with the eigenvalue buckling procedure. However, since an exact solution to the problem is readily developed (see below), the example is a useful illustration of a simple, geometrically nonlinear analysis.

Two simple models are possible with Abaqus—one using a single truss element of type T2D2, and one using a SPRING element. There are two differences between these two models. One is the way strain is measured. Because the truss element is usually used with the standard constitutive models in Abaqus, it uses logarithmic strain. With the spring, the “strain” is calculated from the change in distance between its ends. The second difference is that the force in the truss is calculated as the stress times the area, and the area is updated as the truss deforms, using the assumption that the truss is incompressible and so has constant volume. In the spring, the force is defined immediately by the spring rate that is given in the input data times the “strain.” The exact solutions are, therefore, not the same for the two models, but they show only minor differences because the dimensions are chosen so that the strains are small throughout the deformation. The differences would be significant if large strains were involved.