Problem description

The panel is 319 mm (12.56 in) long and spans a 120° sector of a cylinder, with a midsurface radius of 74.6 mm (2.938 in) and a thickness of 3.18 mm (0.125 in). Only 60° of the panel is modeled because of the symmetry of the problem. Clamped boundary conditions are prescribed on three edges of the model, while the appropriate symmetry conditions are imposed along the remaining edge.

The shell is made from 6061-T6 aluminum alloy with a Young's modulus of 72.4 GPa (10.5 × 106 psi), a Poisson's ratio of 0.33, and a density of 2672 kg/m3 (2.5 × 10−4 lb sec2 in−4). A von Mises elastic, perfectly plastic material model is used with a yield stress of 303 MPa (4.4 × 104 psi).

In the experiment the high explosive layer covers a 60° sector of the panel, extending 259 mm (10.21 in) from one end. Hence, there is no symmetry plane along the y-axis. All nodes in contact with the high explosive layer have been grouped in a node set named BLAST. The effect of the detonation is simulated by prescribing an initial inward radial velocity of 144 m/sec (5650 in/sec) to the nodes in this set.

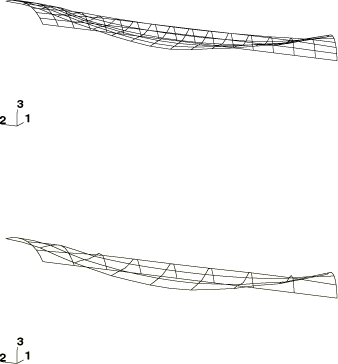

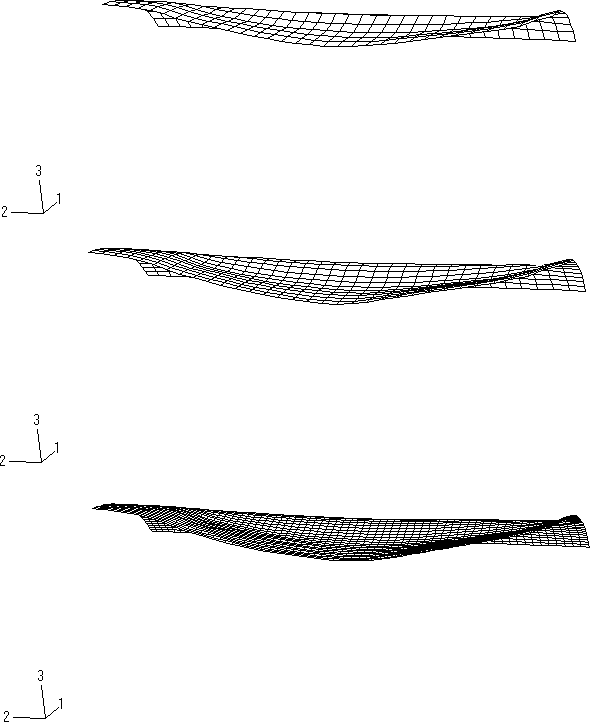

All the relevant shell element types available in Abaqus/Standard are used in the simulation for comparative purposes and as a gauge of the relative merits of each element type for this class of problem. An 8 × 16 mesh is used for first-order elements, and a 4 × 8 mesh is used for second-order elements.

The Abaqus/Explicit analysis is performed using the finite-strain element, S4R, for three different mesh refinements (8 × 32, 16 × 32, and 32 × 64) and the small-strain elements, S4RS and S4RSW, for a 32 × 64 mesh. Geometrically equivalent analyses employing a shell offset with a value of 0.5 are performed using each of the quadrilateral shell elements in Abaqus/Explicit for a 32 × 64 mesh refinement. In addition, an analysis is performed with a 16 × 32 mesh of S4R elements using ENHANCED hourglass control.