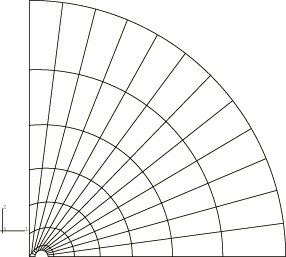

Figure 3

shows the displaced shape of the mesh near the crack tip at steady state.

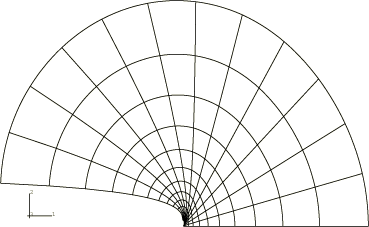

The -integral

is only path independent in the limiting case when steady-state conditions are

reached. The path dependence of

during transient creep is shown in

Figure 4.

The figure shows the variation of

with the radius of the contour, r, measured at different

times during the early part of the creep history (before the transition time,

,

defined at the end of this discussion, is reached). We define the radius for

the nth contour, r, as the distance

from the crack tip to the outer ring of nodes of the nth

ring of elements surrounding the crack tip. Path independence is reached as

time increases. The difference between the second and fifth contour values is

less than 4% at .

This difference decreases further until the values become path independent at

steady state.

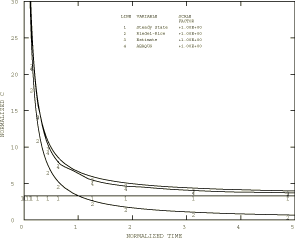

Figure 5

compares the

values predicted by

Abaqus

(Line 4) with the steady-state

value, as well as with two approximate models available in literature. Since

is defined only on a contour of infinitesimal dimension around the crack tip at

early times (before steady-state conditions apply), it is necessary to estimate

its value by extrapolating the values provided by the

Abaqus

contour integral to a contour with zero radius. As explained in

Contour Integral Evaluation,

each contour integral evaluation in

Abaqus

is made by applying a uniform virtual perturbation to the nodes within a ring

of elements surrounding the crack tip. Therefore, in a plane strain case such

as this, the only contribution from the nth contour

integral comes from the nth ring of elements, counting

outward from the crack tip. For the purpose of this extrapolation we use the

same definition of radius for the nth contour integral as

described in the previous paragraph. We ignore the first contour in the

extrapolation, since experience has shown that the first contour is of

significantly lower accuracy than the other contours. The

values shown in

Figure 5

are then based on a least-squares fit of a second-order polynomial

to the four remaining contour integral values provided by

Abaqus

at each time point and recording the value provided by this curve fit at

0.

We have not investigated the accuracy of this extrapolation technique.

The

value shown in

Figure 5

is also obtained by using another technique in

Abaqus.

By interpreting strains and displacements as their rate counterparts and

J as ,

the fully plastic solutions obtained from a power law hardening material can be

applied directly to find

values for an equivalent power law creep model. In other words, power law creep

is analogous to the fully plastic limit of power law hardening plasticity, so

where

is a reference stress;

is the creep strain rate at the reference stress;

is a dimensionless function of the power law exponent, n,

and of geometric parameters; P is the loading; and

is the limit load. For this particular example, however, the applied far-field

tension, ,

is insufficient to cause a fully plastic zone to develop; therefore, the

J value cannot be directly interpreted as

To obtain the

value from an equivalent Ramberg-Osgood material model in such a case, the

following procedure is followed: The structure is loaded until a fully plastic

zone exists in a zone surrounding the crack tip. For this purpose a fully

plastic static analysis is used to monitor the progress of the solution in the

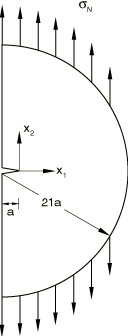

element set containing the 11 rings of radially focused elements (Figure 3).

A fully plastic solution is obtained at a load of 66.3

The J value obtained at this load is then used to evaluate

the calibration function ,

which, in turn, is used to obtain

at a load of

This value is shown as Line 1 in

Figure 5.

Figure 5

also shows the Riedel and Rice (1980) approximation. They proposed the

following relation between

and the stress intensity factor

for small-scale creep:

where n is the power law constant and

E and

are elastic constants. This approximation is shown as Line 2 in

Figure 5.

The remaining curve in

Figure 5,

Line 3, represents the interpolation between short and long time behavior

proposed by Riedel (1981):

where the transition time from small-scale creep to extensive creep is given

by