The elasticity is defined by the Young's modulus, E,

and elastic Poisson's ratio, .

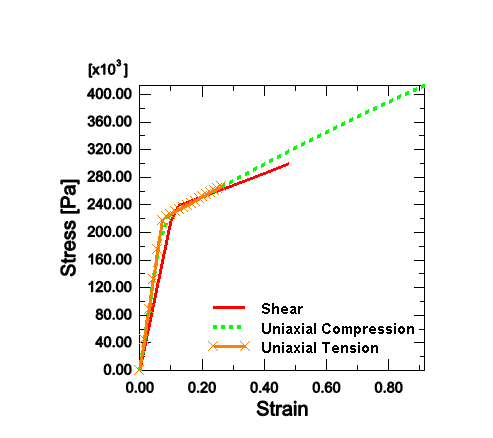

For the crushable foam model with volumetric hardening, the initial yield

surface is defined by k, the ratio of yield stress in

uniaxial compression, ,

to the yield stress in hydrostatic compression,

(this is the initial value of );

and ,

the ratio of yield stress in hydrostatic tension, ,

to the yield stress in hydrostatic compression, .

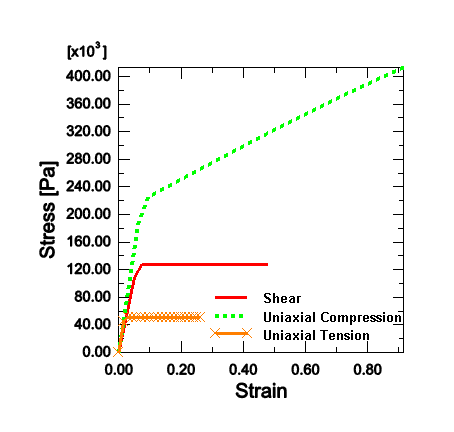

For the isotropic hardening model, the initial yield surface is defined by

k only, but the user needs to provide the plastic

Poisson's ratio, which is the ratio of the transverse to the longitudinal

plastic strain under uniaxial compression. The evolution of the yield surface

is defined by the yield stress versus plastic strain curve in uniaxial

compression. For the rate-dependent version of the model we also need the

inverse viscosity, D, and the viscous power law

coefficient, p.

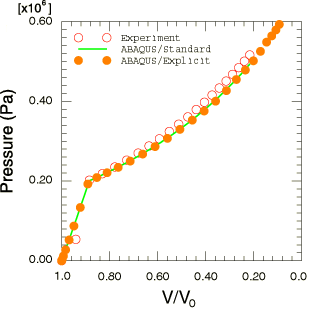

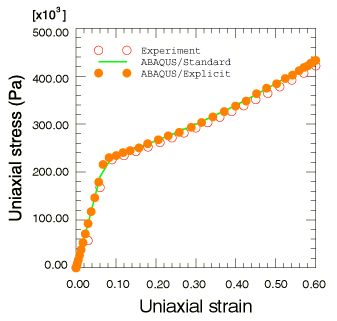

The model is calibrated for a foam (Dytherm 2.5) for which we have only

hydrostatic compression and uniaxial compression data at slow (static) strain

rates. The rate-independent calibration is done as follows. The Young's modulus

and elastic Poisson's ratio can be obtained easily from the experimental data.

From the hydrostatic compression test we immediately obtain the initial yield

pressure, .

From the uniaxial compression test we obtain the initial yield stress in

uniaxial compression, .

For the volumetric hardening model, we also need the strength in hydrostatic

tension. In the absence of tensile test data we assume the tensile strength,

,

to be one-tenth of the hydrostatic compression yield strength

.

For the isotropic hardening model we choose zero plastic Poisson's ratio based

on the experimental observation that uniaxial compression of a specimen shows

almost no lateral strain. The subsequent yield surface is defined by the

hardening curve characterized using uniaxial compression data. The calibration

as described above yields the following material parameters for Dytherm 2.5:

3.0 MPa

0.2

0.22 MPa

0.02 MPa

0.2 MPa (this is the initial value of )

1.1

0.1 (for the volumetric hardening model)

0 (for the isotropic hardening model)

To calibrate the rate dependence parameters D and

p, it would be necessary to have a number of similar

configuration tests performed at different strain rates. Such data are not

available for this material.