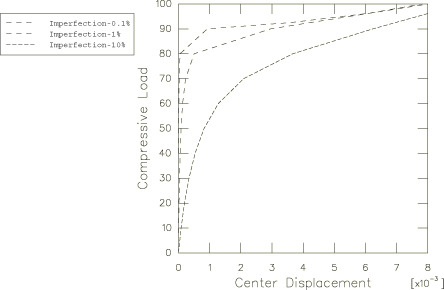

The next phase of a typical collapse analysis is to perform a

load-displacement analysis to ensure that the eigenvalue buckling prediction

already obtained is accurate and, at the same time, to investigate the effect

of initial geometric imperfection on the load-displacement response. In this

way concerns about imperfection sensitivity (unstable postbuckling response)

can be addressed. The eigenvalue analysis is useful in providing guidance about

mesh design for these more expensive load-displacement studies: mesh

convergence studies can be performed as part of the eigenvalue analysis, which

is usually significantly less expensive than the load-deflection analysis.

For the load-displacement analysis the perfect geometry must be “seeded”

with an imperfection to cause it to collapse. It is possible that a problem run

with perfect geometry may never buckle numerically at reasonable load levels

because the model has absolutely no prebuckled displacement in the postbuckled

mode and, thus, no ability to switch to that mode. Presumably an imperfection

in the form of the buckling mode would be the most critical. In this example,

for simplicity, we use instead a bilinear imperfection:

So long as the imperfection contains the mode into which the structure

wishes to collapse, it is presumed that any imperfection will provide the

necessary perturbation of the solution.

The imperfection magnitude,

is taken as 0.1%, 1%, and 10% of the plate thickness. Since we expect a buckle

at a load of about 90.4, the edge load is applied by requesting that the load

be increased monotonically up to a value of 100, starting with an increment of

10. Normally the Riks method would be chosen if the postbuckling response is

unstable. It is not necessary for this case.

In all cases where a sudden loss of stiffness is expected (as here, when the

imperfection is very small) it is essential that equilibrium be satisfied

closely; otherwise it is possible for the solution to fail to switch to the

alternate branch of the solution. The default equilibrium tolerances used in

Abaqus

are rather tight by engineering standards, as experience shows that less

demanding equilibrium control may fail to pick up the buckle in the case of

almost perfect geometry.