Stampable, Turnable, and Drillable Surfaces | ||||||

|

| |||||

| CLIENT / Applicable for | SHAPE_CONTROLLER | SHAPE_SENSITIVITY |

|---|---|---|

| SURF_STAMP | OK | OK |

| SURF_TURN | OK | OK |

| SURF_DRILL | OK | - |

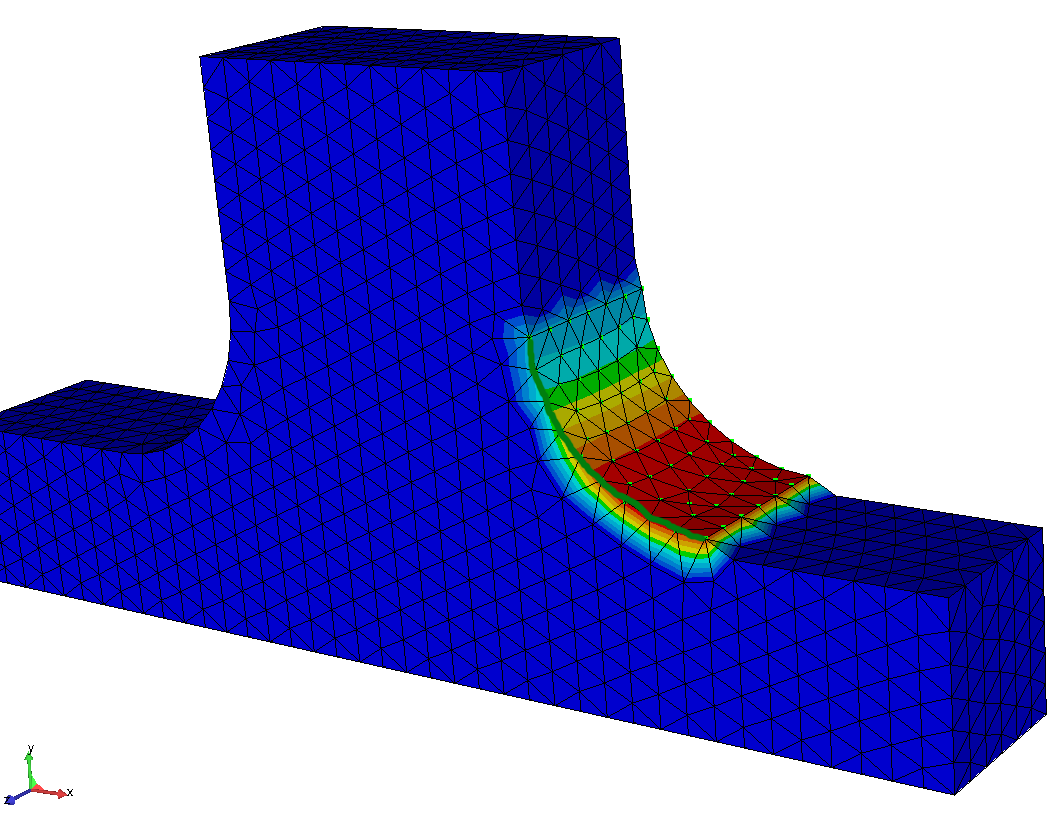

Stampable Surface (SURF_STAMP) for Shape Controller

Maintaining a stampable surface during optimization involves defining

a stamping direction. The stamping domain is defined using a node group.

The direction defined by the CLIENT_DIR parameter specifies

the stamping direction. The link condition is defined using the following

parameters:

CLIENT = SURF_STAMP

CLIENT_DIR = <x_1>,<x_2>,<x_3>

CS = name_of_coord_system

The main nodes are found using the standard main criterion. The stamping surface is defined using the given stamping direction and the cutting edge automatically generated by Tosca Structure. All nodes of the node group are linked to this surface.

An additional demolding direction can be included:

DEMOLD_DIR = <x_1>,<x_2>,<x_3>

The demolding direction must be orthogonal to the client direction. Therefore, Tosca Structure projects the demold vector onto a plane normal to the client direction.

Important:

|

Stampable Surface (SURF_STAMP) for Shape Sensitivity

A surface is stampable if all nodes lie in the same plane.

Enforcing stampable surfaces is supported for sensitivity-based shape optimizations as well.

The most important parameter is the stamping direction, defined by the CLIENT_DIR parameter.

Another mandatory parameter is the main group, that defines the reference edge or cutting edge for the plane where all nodes shall be moved in.

The link condition is defined using the following

parameters:

CLIENT = SURF_STAMP

CLIENT_DIR = <x_1>,<x_2>,<x_3>

CS = name_of_coord_system

MAIN = NDGR, main_node_group

In the figure below, the green dotted points are used as the stamping area and the green

highlighted edge is used as the main group.

| Important:

|

Turnable Surface (SURF_TURN) for Shape Controller

Maintaining a turnable surface during optimization involves defining a rotation axis. The domain that assures a turnable surface is defined using a node group; all nodes of the specified surface node group are checked for rotation symmetry in the given rotation axis. The link condition is defined using the following parameters:

CLIENT = SURF_TURN

CLIENT_DIR = <x_1>,<x_2>,<x_3>

CS = name_of_coord_system

The direction defined by the CLIENT_DIR and the origin

of the coordinate system specify the exact position and direction of

the rotation axis.

The main nodes are found using the standard main criteria. In

addition, the criteria MAIN = AUTO is available for compatibility

reasons with sensitivity-based shape optimization. It can be seen as an alias for

MAIN = MAX. The turning surface is defined using the given

rotation axis and the cutting edge automatically generated by Tosca Structure. All nodes of the node group are linked to this surface.

Important:

|

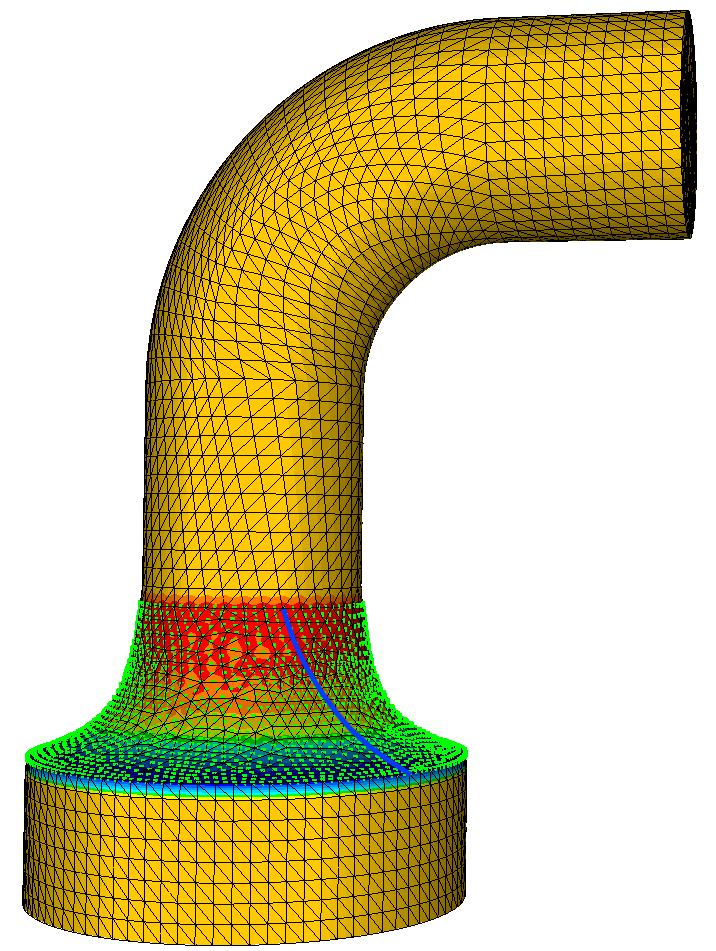

Turnable Surface (SURF_TURN) for Shape Sensitivity

The SURF_TURN manufacturing constraint for sensitivity-based shape optimization can be used

to achieve a turnable or rotational symmetric surface.

The important parameters are the rotational axis CLIENT_DIR, together with the origin,

specified by a coordinate system CS.

Next, the specification of "driving" area (MAIN) is a necessary part of the setup. It can

either be defined by providing a node group (NDGR, <node group name>), which gives very good control,

or by letting Tosca find an appropriate area, which is very simple on the setup side but can fail for complicated surfaces.

The link condition is defined using the following parameters:

CLIENT = SURF_STAMP

CLIENT_DIR = <x_1>,<x_2>,<x_3>

CS = name_of_coord_system

MAIN = NDGR, main_node_group | AUTO

In the figure below, the green dotted points are used as turning area and the blue

highlighted edge is used as the driving area.

| Important:

|

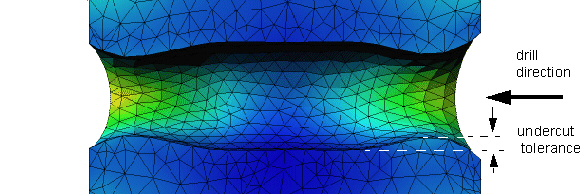

Drillable Surface (SURF_DRILL)

The drill restriction is a combination of the turning and the demolding restriction. Maintaining a drillable surface during optimization involves defining the drill axis and the drill feed. The drilling domain is defined using a node group; all nodes of the specified surface node group are checked for drilling in the given drill direction. The link condition is defined using the following parameter:

CLIENT = SURF_DRILL

CLIENT_DIR = <x_1>,<x_2>,<x_3>

CS = name_of_coord_system

ANGLE = <real> (0° < angle < 45°)

The direction defined by the CLIENT_DIR and the origin

of the coordinate system specify the exact position and direction of

the drill axis, the angle specifies a minimum surface angle.

The shape of the drilling surface can be specified with an additional undercut tolerance. The term 'drilling surface' in this case should be interpreted in a more general sense.

UNDERCUT_TOL = <real> (>0)

|

Important:

|