About the Bending Plate Example | ||

| ||

About the Model

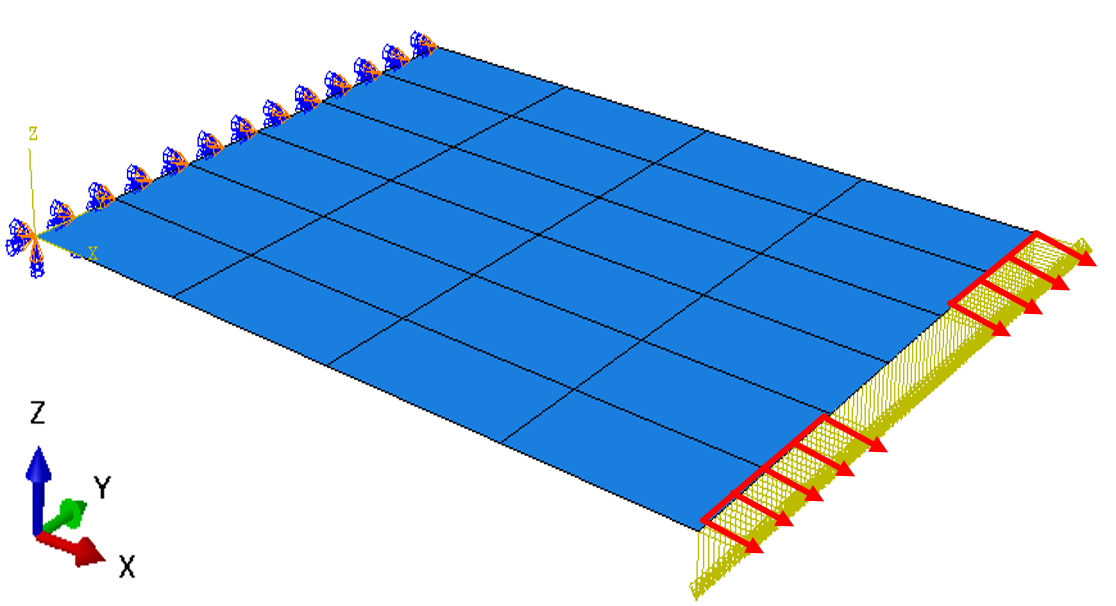

In this model, a clustered plate is encastered on the left side with two forces on the right side. One load of L= 2 N per node in negative Z-direction for all nodes and another load L/10 N per node in positive X-direction onto the nodes of the outer thirds.

In this example, it will be shown how the differences of linear and nonlinear kinematics (NLGEOM=OFF/ON) affect the optimization results. The sizing optimization task is to minimize the displacement of the right nodes in X-direction while using 90% of the initial volume. By default, the shell thicknesses are allowed to change up to 25% of the initial thickness and is changed for each element cluster. Within a cluster, the elements will have the same thickness.

Procedure Summary

| Model: | Bending_Plate_NL, Bending_Plate_LIN |

| Design Area: | All elements |

| Objective: | Minimize displacement in X-direction of the nodes of the right edge |

| Constraint: | Relative volume of less or equal 90% |