Minimum Member Size Control

Thin trusses in the resulting structure are often undesirable, depending on the manufacturing process. Defining a minimum thickness avoids the creation of small substructures in the final result.

The minimum member size control feature ensures the mesh independence of the results. A coarse mesh and a fine mesh lead to the same optimized topology if the minimum member sizes for both cases are set to the same absolute size.

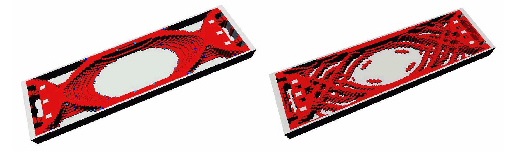

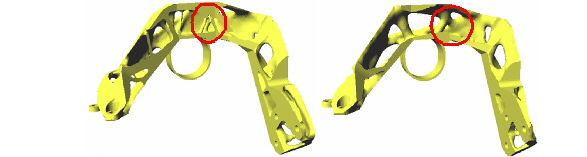

Optimized engine support with and without MINIMUM member size restriction is presented in the following figure:

|

- It is impossible to ensure the accurate minimum thickness of the structures. For some cases, the results contain parts with a diameter smaller than the defined minimum member size.

- The CPU-time for the calculation increases quadratically with the minimum member size. To save calculation time, the recommendation is to only define the restriction in areas of the model where thin parts must be avoided. To identify these areas, the first step is to perform an optimization without restrictions.