-

Define a numerical variable (VARIABLE) that contains the maximum stress value

of the nodes in the primary notch:

VARIABLE

ID_NAME = REF_NODE_STRESS

DEF_TYPE = SYSTEM

UPDATE = EVER

TYPE = SIG_MISES

ND_GROUP = REFERENCE_NODES

GROUP_OPER = MAX

END_

The variable stress value is updated in each iteration.

-

Define a Design Response (DRESP) with the maximum von Mises Stress in the design area:

DRESP

ID_NAME = DRESP_VON_MISES

DEF_TYPE = SYSTEM

TYPE = SIG_MISES

ND_GROUP = design_nodes

GROUP_OPER = Max

END_

-

Reference the Design Response and Variable in the Objective Function (OBJ_FUNC):

OBJ_FUNC

ID_NAME = minimize_deviation

DRESP = DRESP_VON_MISES, ,REF_NODE_STRESS

TARGET = MINMAX

END_

The objective function of the optimization problem is to minimize the deviation

of the stress values in the design area from the variable reference values.

That means the maximum stress value in the design area (secondary notch) is closer to the stress level found in the reference area (primary notch)

where the stress level in the primary notch is lowered.

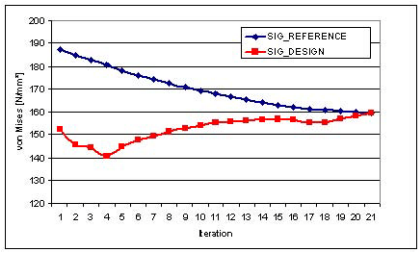

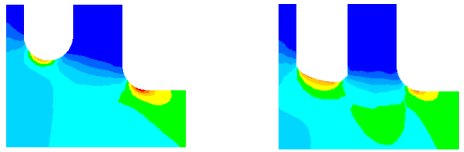

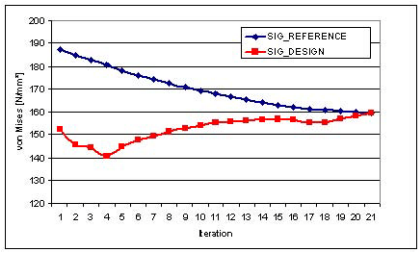

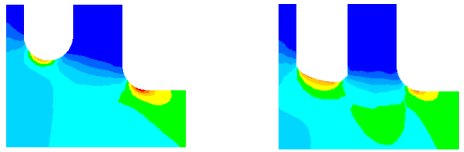

The result looks as follows:

The stresses at the reference nodes in the design area are drastically minimized

through the optimized relief notch: