Optimizing the Shaft Model | ||

| ||

-

Define input data, additional groups, and design variables.

FEM_INPUT ID_NAME = MY_INPUT_FILES FILE = shaft_surfturn_sens.inp END_ include, shaft_surfturn_sens.inc GROUP_DEF ID_NAME = NODES_FOR_DISP TYPE = NODE FORMAT = LIST LIST_BEGIN 13, 440 END_ DV_SHAPE ID_NAME = MY_DV_SHAPE ND_GROUP = design_nodes END_

-

Create geometrical constraints.

-

Rotational Symmetry (SURF_TURN):

LINK_SHAPE ID_NAME = LS_TURN CLIENT = SURF_TURN MAIN = AUTO CLIENT_DIR = 0, 1, 0 CS = CS_0 END_ DVCON_SHAPE ID_NAME = DVCON_SHAPE_SURF_TURN CHECK_BC = NO ND_GROUP = design_nodes CHECK_LINK = LS_TURN END_

-

Node fixations:

CS_DEF ID_NAME = MY_CS DEF_TYPE = LOCAL CS_TYPE = CYLINDRICAL CS_REF = CS_0 ORIGIN_123 = 0, 0, 0 ROTATION_321 = 0, 0, 270 END_ DVCON_SHAPE ID_NAME = DVCON_SHAPE_FIXED CHECK_BC = NO ND_GROUP = nodes_fixed CHECK_DOF = MY_CS, FIX , FREE, FREE END_

-

Shrink control:

DVCON_SHAPE ID_NAME = SHRINK_CTRL CHECK_SHRINK = 3. ND_GROUP = design_nodes END_

-

Rotational Symmetry (SURF_TURN):

-

Create a constraint for the volume.

-

Define a Design Response with the volume (DRESP):

DRESP ID_NAME = DRESP_VOLUME LIST = NO_LIST DEF_TYPE = SYSTEM EL_GROUP = ALL_ELEMENTS TYPE = VOLUME UPDATE = EVER GROUP_OPER = Sum END_

-

Reference the Design Response in a constraint (CONSTRAINT) and constrain it to 100%.

CONSTRAINT ID_NAME = VOLUME_CONSTRAINT DRESP = DRESP_VOLUME MAGNITUDE = REL LE_VALUE = 1.0 END_

-

Define a Design Response with the volume (DRESP):

-

To define the Objective Function (OBJ_FUNC) for the plastic equivalent magnitude (PEMAG)

in the second load case, do the following:

-

Create a Design Response (DRESP).

DRESP ID_NAME = DRESP_PEMAG DEF_TYPE = SYSTEM TYPE = PEMAG EL_GROUP = ALL_ELEMENTS END_

-

Define the objective function.

OBJ_FUNC ID_NAME = OBJ_FUNCTION TARGET = MIN DRESP = DRESP_PEMAG END_

-

Create a Design Response (DRESP).

-

Design responses and optimization functions

DRESP ID_NAME = VOLUME DEF_TYPE = SYSTEM TYPE = VOLUME EL_GROUP = ALL_ELEMENTS END_ DRESP ID_NAME = DISPLACEMENT_X DEF_TYPE = SYSTEM TYPE = DISP_X_ABS ND_GROUP = NODES_FOR_DISP GROUP_OPER = Max CS_REF = CS_0 END_ DRESP ID_NAME = DISPLACEMENT_Z DEF_TYPE = SYSTEM TYPE = DISP_Z_ABS ND_GROUP = NODES_FOR_DISP GROUP_OPER = Max CS_REF = CS_0 END_ OBJ_FUNC ID_NAME = MY_OBJ_FUNC TARGET = MINMAX DRESP = DISPLACEMENT_X, , DRESP = DISPLACEMENT_Z, , END_ CONSTRAINT ID_NAME = VOLUME_CONSTRAINT MAGNITUDE = REL DRESP = VOLUME LE_VALUE = 1.0 END_

-

Mesh regularization

MESH_SMOOTH ID_NAME = MY_MESH_SMOOTH CORRECT_ELEMENTS = YES FREE_SF = FREE MS_LAYER = design_nodes, 4 FREEZE_DESIGN_NODES = YES END_

-

Reference the Design Variables, Objective Function, and Constraints as well as DVCONs in

the OPTIMIZE command.

OPTIMIZE ID_NAME = MY_OPTIMIZATION_TASK OBJ_FUNC = MY_OBJ_FUNC DV = MY_DV_SHAPE CONSTRAINT = VOLUME_CONSTRAINT STRATEGY = SHAPE_SENSITIVITY DVCON = DVCON_SHAPE_SURF_TURN DVCON = DVCON_SHAPE_FIXED DVCON = SHRINK_CTRL MESH_SMOOTH = MY_MESH_SMOOTH END_

-

Set stop condition.

STOP ID_NAME = MY_STOP ITER_MAX = 150 END_

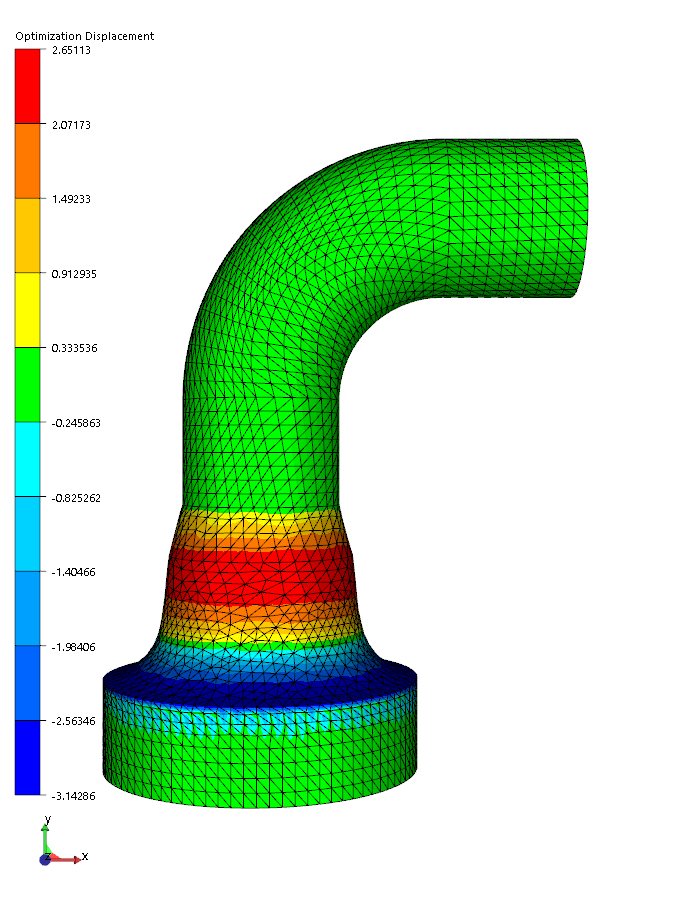

The optimization result looks as follows: