Elements tested

QEC3D8 QEC3D8R

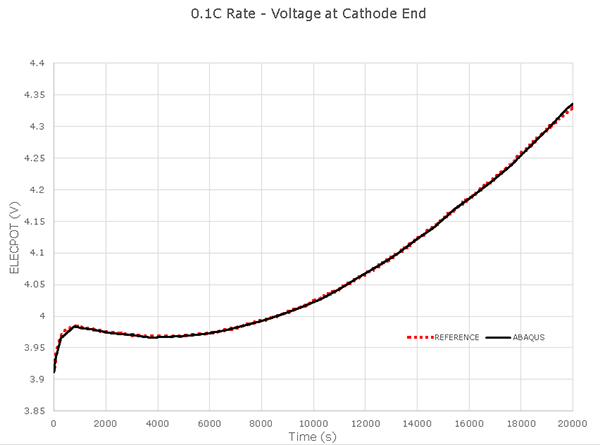

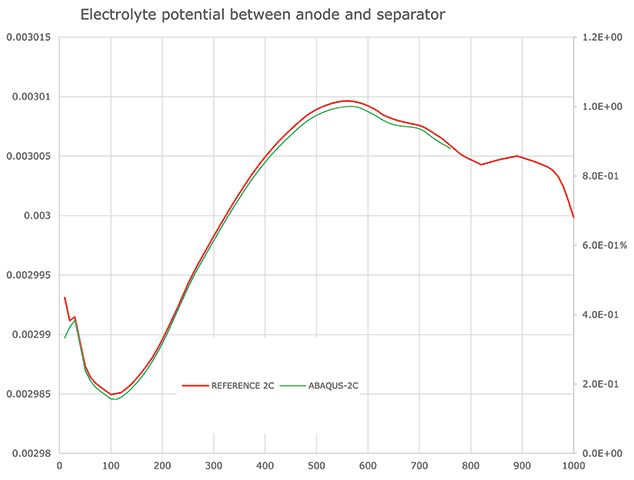

Products Abaqus/Standard Elements testedQEC3D8 QEC3D8R Features testedThis verification problem tests the thermal-electrochemical behavior of a half-cell battery modeled using a lithium metal anode and a porous cathode. The lithium ion battery involves the solution of lithium ion diffusion in the electrolyte and the porous electrodes, as well as the charge transfer process that is captured by the 3D formulation of Newman's porous electrode theory. The interaction of the solid anode with the separator is modeled using a Butler-Volmer surface interaction load. All associated thermal effects such as heat losses, temperature evolutions, and temperature-dependent properties are considered in the test cases. Problem descriptionThe problems test the lithium metal battery cell charging capabilities at different charge rates, as described in Donnelly Masters thesis. The results compare very well with that shown in Donnelly Masters thesis. Model:The geometric and other relevant parameters, including individual electrode thicknesses, of the cell are as described in Donnelly Masters thesis. The total length, width, and thickness of the electrode stack are 0.101 m, 0.085 m, and 0.000147 m, respectively. Mesh:The finite element model consists of 44 elements each of type QEC3D8 or QEC3D8R. The solid anode is modeled with one element through the thickness. The porous cathode and separator elements are modeled with 25 and 18 elements, respectively. Only one element is used in the plane because the setup is essentially 1D. The QEC3D8 and QEC3D8R elements support thermal-electrochemical degrees of freedom. Material:The anode material is solid lithium, and the cathode is made up of lithium cobalt oxide (LCO). The thermal-electrochemical properties of the different regions described in Donnelly Masters thesis are used in the models included in this section. An Arrhenius-type temperature dependence is used for several of the properties. Loading:The battery is subjected to currents that correspond to a 0.01C, 1C, and 2C charge analysis. Results and discussionFigure 1 displays the charge curves predicted by Abaqus, showing the evolution of the voltage difference across the cell during charge as a function of time for 0.1C rate and the simulation results from Donnelly Masters thesis for the same C rate. A reasonably good correlation is observed. Input files

Input files to model a half-cell lithium battery with *MULTIPHYSICS LOAD

References

Figures   | |||||||