Isosurface and Smoothing Parameters | ||

| ||

Following parameters control the generation and the smoothing of

the isosurface. They are used when the isosurfaces of the material

distribution resulting from topology optimization are calculated: in

this case, the parameter TASK is set to iso (single isosurface) or all_iterations

(isosurfaces for all iterations). In addition, the parameters

SELF_INTERSECTION_CHECK and MIN_ANGLE

are used during the data reduction that is described in details in the

next section.

Isosurface generation and smoothing parameters of Tosca Structure.smooth |

|||||

|---|---|---|---|---|---|

Parameter |

Value |

Description |

Supported by |

||

GUI-TS.pre |

GUI-TS.smooth |

TExt |

|||

ISO_VALUE |

Real value between 0 and 1 Default: 0.3 |

Isovalue; is used to determine the positions on the element edges where the new nodes are created. Larger values lead to models with smaller volume. See below for an example. |

x |

x |

x |

SMOOTH_CYCLES |

Non-negative integer number Default: 5 |

Number of smoothing cycles; if set to 0, no smoothing is performed. Larger values lead to smoother models, but may cause the narrowing of thin components. |

x |

x |

x |

ORIGINAL_SURFACE_SMOOTHING |

off (original surface is not smoothed) shrink (limited original surface smoothing) full (original surface is smoothed) default:off |

Defines if the smoothing of the original surface is to be performed. If set to shrink, the original surface gets smoothed by moving its nodes toward the inside of the model only, so that the restrictions on the design region are not violated. |

x |

x |

- |

SELF_INTERSECTION_CHECK |

off (no checks) check (check once) runtime (check always) iterative (first run without check, rerun if required) Default: iterative |

Defines if the self-intersection checks are to be performed during the isocut, smoothing, and data reduction. See below. |

x |

x |

- |

MIN_ANGLE |

Real value between 0 and 90 Default: 15 |

Defines the minimal angle of the triangles that result from the smoothing and data reduction; triangles with smaller angles might be present if they are created during the isocut. Too large value might prevent the smoothing; too small value might lead to degenerated triangles. |

- |

x |

- |

All parameters have default values that are useful in most cases. However, these parameters affect the appearance of the isosurface as described below.

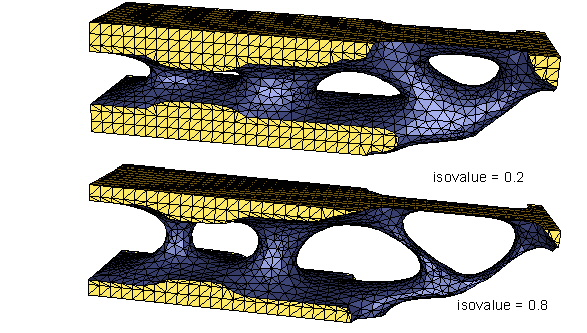

The isovalue specified using the parameter ISO_VALUE defines

the position between the elements with zero and maximal material value

where the isosurface is constructed. More precisely, the interpolated

material values are first found for each node, and then the new nodes

are constructed on the edges that have varying material values (that is,

the material value for one end is less than and for the other one larger

than the isovalue). The ratio in which the edge is subdivided by the

new node is defined by the isovalue in respect to the material values

of the ends of the edge, but is limited to a range from a to 1-a with

a constant value a (currently 0.3) in order to prevent edges of very

small lengths. As the result, increasing the isovalue leads to shifting

the isosurface toward the inside of the model, thus the model volume

decreases.

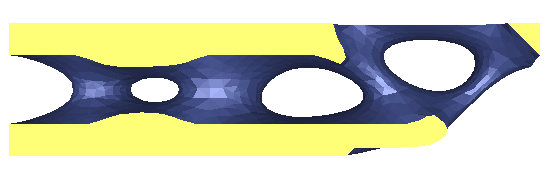

See the following figures, how the isovalue influences the result.

|

| Important:

In case that the structure becomes disconnected, it is advised to repeat the calculation with smaller isovalue. Still, if the model contains a single layer of elements or a string of elements connected by nodes only, the isosurface will probably be disconnected for any isovalue. In this case, it is recommended to repeat the topology optimization with

adjusted minimal thickness of components that can be specified by choosing

the minimal member size in |

After the isocut is done, the surface smoothness is generally not

sufficient. Therefore, the iterative smoothing is performed by displacing

the nodes created in the isocut. The smoothing is done in cycles; the

number of cycles is determined by the parameter SMOOTH_CYCLES.

The conditions for a node displacement to be accepted is that the angles

of the resulting triangles are larger than a certain value specified by the

parameter MIN_ANGLE, and, if requested, that no surface self-intersections

occur after the displacement.

The second check is not done if the SELF_INTERSECTION_CHECK

parameter is set to off or check; the difference in

these cases is that, in case this parameter is set to check,

the self-intersection test is performed once for the entire model after

the smoothing and data reduction are made, and the user receives the

information about the number of intersecting faces. In case that the SELF_INTERSECTION_CHECK

parameter is set to iterative, the smoothing is first performed

without the self-intersection checks, and then is redone if the self-intersections

appear after the smoothing.

| Important:

Note that in case of the |

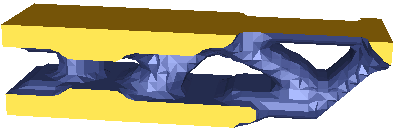

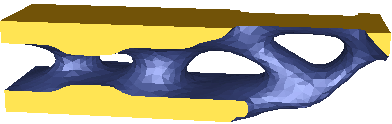

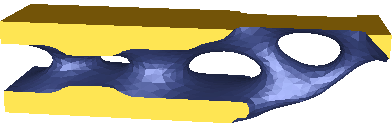

In order to achieve smoother surfaces, higher value of SMOOTH_CYCLES

parameter should be used. However, this leads to the increase of the

computation time that might be noticeable especially in the case that

the self-intersection test is turned on. In practice, 5 to 10 smoothing

cycles are usually sufficient. Further smoothing might have a negative

effect of contracting thin components; in certain cases, the smoothing

must be turned off by setting SMOOTH_CYCLES to 0.

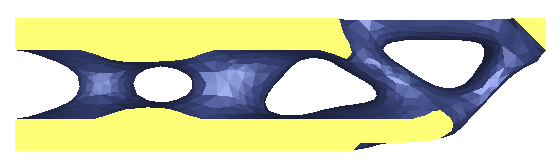

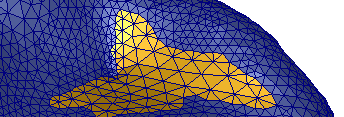

See the following figure for an example of smoothing with various numbers of smoothing cycles:

|

0 smoothing cycles (smoothing turned off) |

|

3 smoothing cycles |

|

10 smoothing cycles |

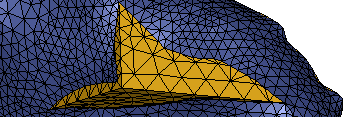

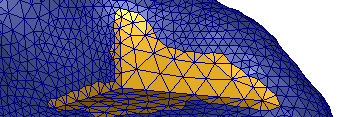

A higher number of smoothing cycles can cause some shrinkage effects

on the surface that is being smoothed. Especially areas with a high curvature

can be changed drastically. If you want to prevent these effects, the

parameter SHRINKAGE_CORRECTION can be set to YES.

Activating the correction will reduce the smoothing efficiency slightly.

A higher number of smoothing cycles might be necessary.

|

shrinkage correction deactivated |

|

shrinkage correction activated |

The parameter ORIGINAL_SURFACE_SMOOTHING defines

if the original surface (that is the part of the surface of the original

elements, in contrast to the new surface produced by isocut) should be

smoothed.

|

ORIGINAL_SURFACE_SMOOTHING = off |

|

ORIGINAL_SURFACE_SMOOTHING = shrink |

|

ORIGINAL_SURFACE_SMOOTHING = full |

If it is set to off, the original surface remains unchanged.

In most cases, this is desired since the surface nodes might have some

additional information (for example, forces or boundary conditions) associated

with them. However, the resulting surface will be smoother if the original

surface gets modified as well. To do this, set ORIGINAL_SURFACE_SMOOTHING

to full.

The third option ORIGINAL_SURFACE_SMOOTHING

= shrink allows modifying the original surface, but in a way

that the new surface does not occupy the region beyond the initial design.

This is achieved by prohibiting the nodes to be moved toward the outside

of the model.

| Important:

Note that the surface of the frozen regions that are chosen using

|