Overview of Thermal Design Responses | ||

| ||

Analysis Types: Thermal Analysis

For optimization based on thermal results temperature (defined using nodes), reaction flux (defined using nodes) and internal flux (defined using nodes and elements) is available for objectives and constraints. Those design responses can be used for conduction or convection loadcases. Radiation is not supported.

You can also setup a static-thermal optimization by referencing multiple inputs decks, one with the thermal and one with the static loadcase:

FEM_INPUT

ID_NAME = MY_INPUT_FILES

FILE = topo_thermal.inp

FILE = topo_static.inp

END_

But please note, that coupled analysis is not allowed.

Tosca Structure supports different heat transfer mechanisms defined as material parameters or boundary conditions.

Updating the convection during topology optimization

iteration history: The convection is automatically updated during the

topology optimization iterations as the surface is changing when elemental

material is added and removed. However, the user has the possibility

to enforce that the convection in the original model should be kept

during the topology optimization iterations. By default, the convection

is only updated when a thermal design response is also included

in the optimization formulation (OPTIMIZE). Nevertheless,

the user can enforce that the convection is always updated during the

optimization iterations. The user can control the update of the convection

using the command block OPT_PARAM, item UPDATE_CONVECTION:

THERMAL_OPT: The convection is modified modified to include new surfaces generated during the optimization only if a thermal design response is included in the optimization formulation (OPTIMIZE).EVER: The convection is always modified to include new surfaces generated during the optimization.NEVER: The convection is not modified during the optimization iterations. Therefore, the original convection is kept and used for all iterations during the optimization.

Command in Parameter File

The design responses (DRESP)

for thermal are defined in the following way:

DRESP

ID_NAME = ...

TYPE = ...

DEF_TYPE = SYSTEM (DRESP for internal force)

GROUP_OPER = MAX or SUM

ND_GROUP = ... (insert the element group)

EL_GROUP = ... (insert the node group, only required for INTERNAL_HFLUX)

END_

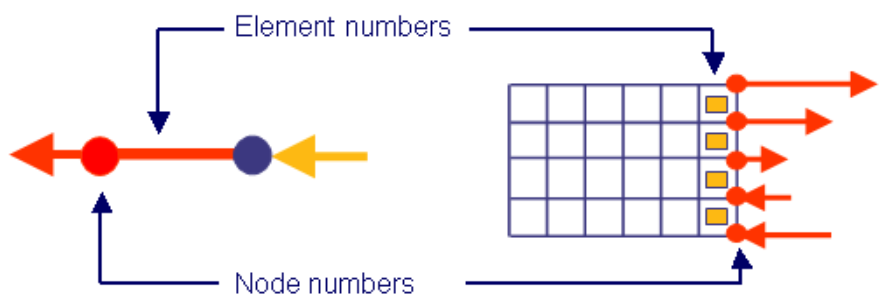

INTERNAL_HFLUX is defined by nodes and elements

as shown in the figure below.

Remarks:

- In Abaqus,

conduction is defined using the material card

*Material, name= *Conductivity

Note that identical material cards are required in both structural and thermal finite element input file, respectively. - In Abaqus,

convection is defined using the option

*Sfilm

- In Abaqus, only DC3xx elements are supported. The thermal elements DC3xx correspond to C3xx elements in the correlating static analysis file with the same number and some node numbers.

- Thermal elements with linear interpolations are to be preferred. Thermal elements with higher-order interpolations can cause instabilities for the analysis.

- Good topology optimization results require a fine mesh.