Guide for Nonlinear Models | ||

| ||

Solver Settings

To obtain better convergence behavior, use the following settings when running an optimization with a nonlinear model:

*STEP, NLGEOM=YES, INC=10000, extrapolation=NO ** (INC=number of increments) *STATIC **(initial, step time, min, max) 0.1, 1.0, 1e-14, 1.0

In the following, Abaqus related remarks that should be taken into account when optimizing structures with nonlinear behavior are summarized.

| Topic: | Remark: |

|---|---|

| Time increment | By default, Abaqus

uses the automatic time incrementation based on the initial, step time, minimum, and maximum time

increments. In the case of a nonlinear analysis,

it is recommended to use a small minimum time increment as well as a higher number of increments

to run a stable analysis. The following default is the syntax for the

Abaqus

input file for the respective step.

*STEP, INC=100

** (INC=increments)

*STATIC

** (initial, step time, min, max)

1.0, 1.0, 1e-05, 1.0

Having a minimum time increment smaller than 1e-07 might further improve the

convergence but also strongly increases the computation time. More details can be found in the

Abaqus documentation. |

| Element type | Based on the utilized integration schemes the element types are split

into fully integrated elements like C3D8 or C3D4 and reduced integrated elements like C3D8R. In the

case of reduced integration elements in the model, activate the enhanced hourglass technique. The

following is the syntax for the Abaqus

input file:

|

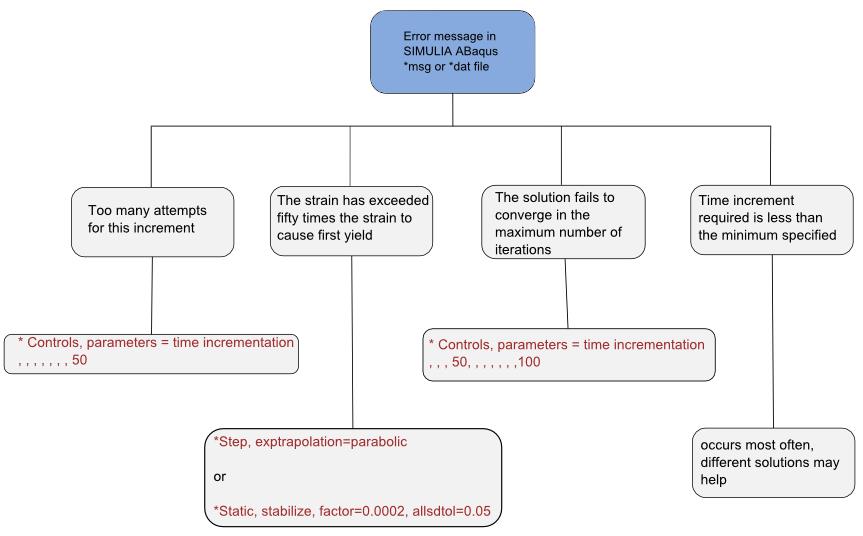

| Solver instabilities | If the optimization fails because of Abaqus

convergence issues, further details can be investigated in the *.msg or *.dat files generated

by Abaqus in the critical step. The following are the

most expected warnings or errors:

|

| Stabilization and contacts | In nonlinear static problems, instabilities like buckling or material

softening might occur. If these instabilities are localized, there a local transfer of strain energy

occurs from one part to another and global solution methods might not work. Here, automatic

(artificial) damping stabilization might help. The damping might help to get the model to converge but

at a loss of convergence speed and accuracy. Therefore, the damping factor is best to be chosen

as small as possible. The ratio of stabilization dissipation energy (ALLSD) to internal energy

(ALLIE) of the whole model should not be bigger than 5%. By default, the value is

FACTOR=2e-4. The following is the syntax for the

Abaqus

input file for the respective step:

It might also help to use

for contacts to relax the liner penalty stiffness. The default is 1.0.

Note:

A “good” value for the damping factor can be different from one model to another. In cases with

contact modeling, rigid body motion might occur while the contact is not fully established.

By using *CONTACT CONTROL, STABILIZE, artificial damping is

introduced to increase stabilization. The damping coefficient is calculated automatically by default

if no value is assigned.

Note:

When using step and contact stabilization simultaneously, a type of

"over-damping" occurs and the result becomes physically unrealistic. Therefore, a combination

of both commands is not recommended.

|

| Solving convergence problems | For some convergence issues, it is not required to change the physics

of the models at all. The following warnings/errors can be found in the *.msg file.

|

| Other step settings | Quite often the error message is not specific or might have different

causes. Therefore, a few additional commands are mentioned in the following

that might help to get the model to converge.

|

Error Messages in .msg-files

|

The above error messages appear most often in the .msg file during a failed optimization. The corresponding command might solve the problem. The error “time increment required is less the minimum specified” occurs with different problems and cannot be solved with a single command. It helps to analyze the model with respect to tie contact, plasticity, element size, and other instabilities.