General Information | ||

| ||

Starting with the design area (which represents the sheet structures to be modified) and with the boundary conditions, such as loads, fixtures and manufacturing conditions, the optimization system will determine a new thickness distribution by modification of the shell thicknesses in the design area. This design proposal should fulfill all mechanical requirements and often represents a weight-optimal design proposal. Sizing with Tosca Structure allows changes for each single shell element in the model as well as clustering of thicknesses, that is, simultaneous modification of shell thicknesses for specific areas.

For the optimization, the following constraints and objectives can be applied:

- stiffness (compliance and displacements);

- eigenfrequencies;

- internal and reaction forces;

- weight, volume;

- center of gravity;

- moment of inertia.

Different constraints can be defined, like member size constraints, freezing of parts, symmetry, and different coupling constraints.

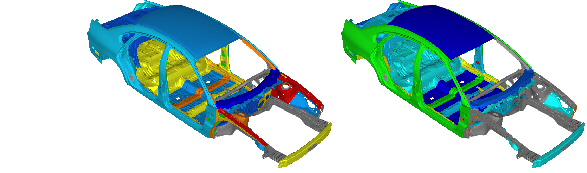

As a result, the optimization creates a design proposal with new shell thicknesses. This design proposal can then be transferred back to your CAD system. The following figures demonstrate sizing for chassis components.

|