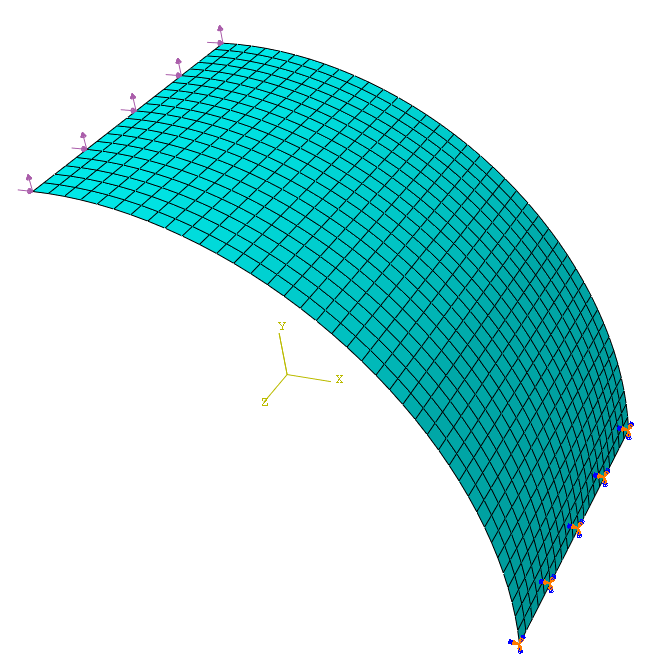

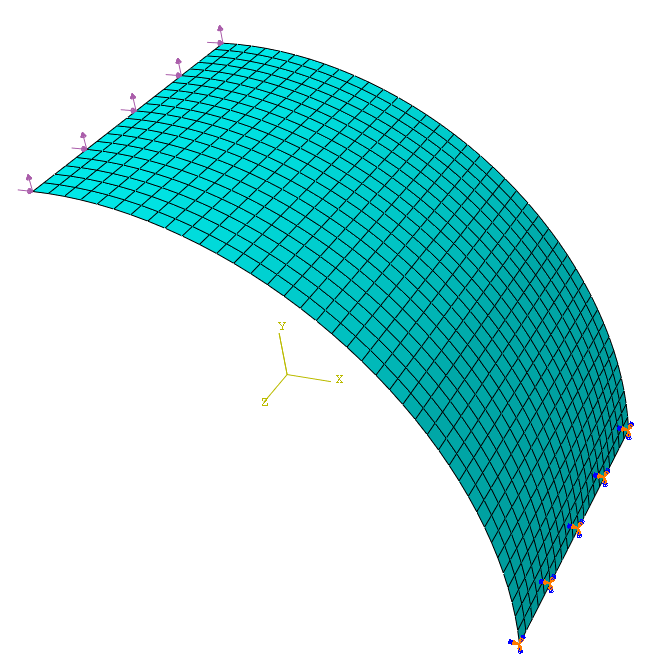

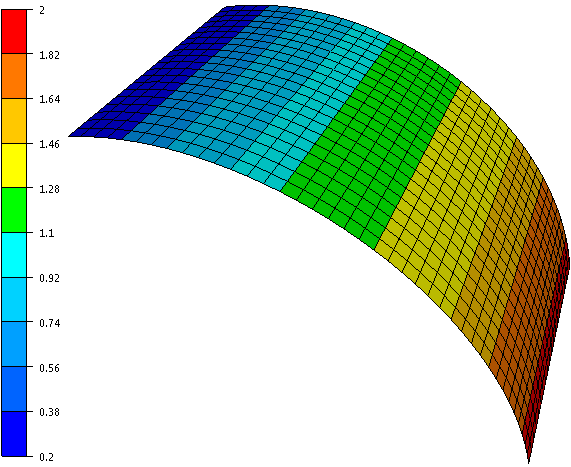

FE Model

The model is a curved shell fixed at one edge and loaded in the X and Y

directions on the opposite edge. To obtain mechanically sensible results

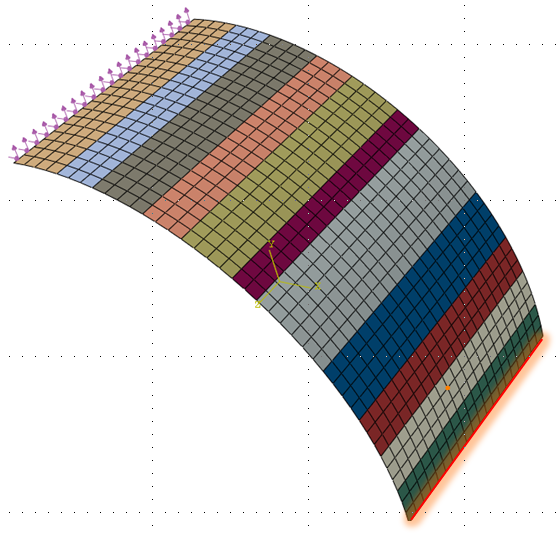

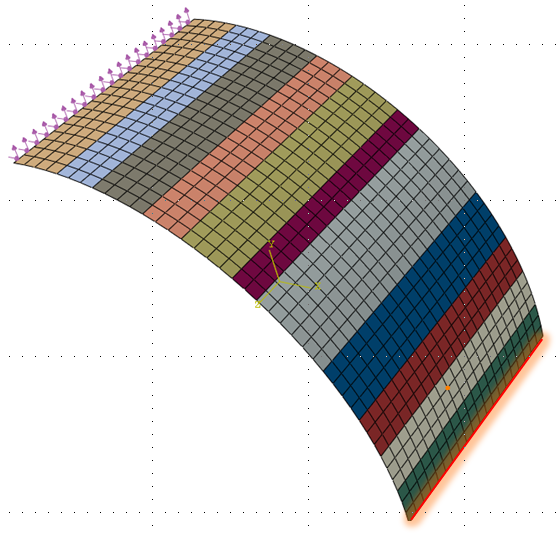

from the optimization, the elements are clustered into 11 groups. Thickness

of each group will correspond to one design variable.

| FE Model |

Clustering |

|

|

Optimization Problem

We consider a basic compliance minimization problem with a volume constraint.

The *.par file is shown below.

DVCON_SIZING

ID_NAME = DVCON_SIZING_set_discr

EL_GROUP = ALL_ELEMENTS

CHECK_TYPE = DISCRETE

DISCR_LIST_FILE = Sheet_sizing.csv

DISCR_CYCLE = 10

DISCR_INTERVAL = 4

DISCR_FRACTION = 0.2

DISCR_CHANGE = 10

END_

DVCON_SIZING

ID_NAME = DVCON_SIZING_bounds

EL_GROUP = ALL_ELEMENTS

CHECK_TYPE = THICKNESS_BOUNDS

MAGNITUDE = ABS

LOWER_BOUND = 0.1

UPPER_BOUND = 2.0

END_

. . .

OPT_PARAM

STOP_CRITERION_ITER = 30

END_

Optimization Results

The following table contains the discrete thickness values which

were available for the considered optimization.

| Available thicknesses: |

| 0.152;0.163;0.170;0.191;0.208;0.229;0.246;0.267;0.305;0.343;0.378;0.417 |

| 0.455;0.531;0.607;0.683;0.759;0.836;0.912;1.062;1.214;1.367;1.519;1.709 |

| 1.897;2.278;2.657;3.038;3.416;3.797;4.176;4.554;4.935;5.314;5.695;6.073 |

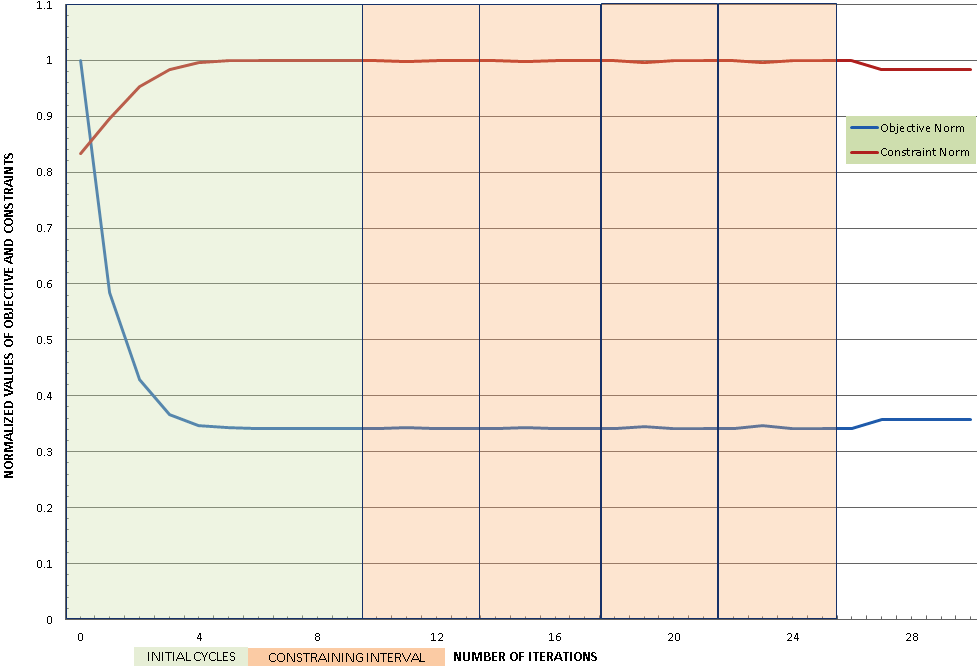

The figure below shows the optimization history of objective and constraints. The constraining cycles and the initial cycles have been marked out.

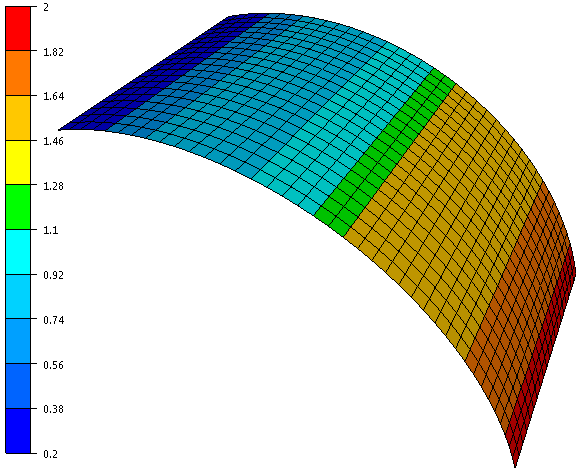

| Optimized discrete thicknesses: |

| 0.3780;0.6070;0.7590;0.9120;1.0620;1.2140;1.5190;1.5190;1.7090;1.7090;1.8970 |

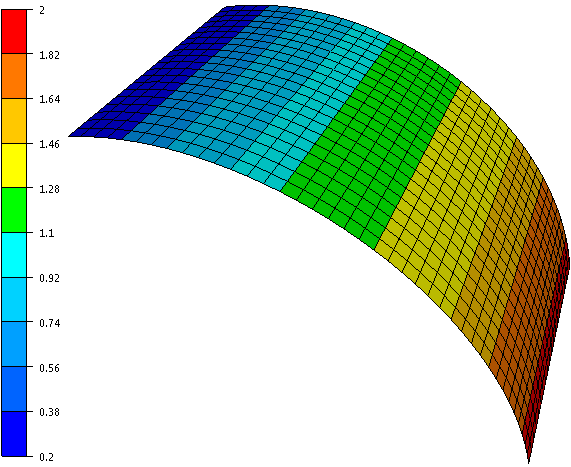

| Resulting thicknesses using sizing optimization with discrete design variables |

|

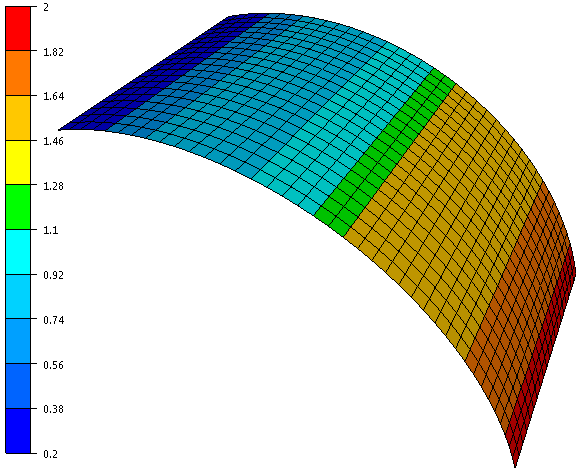

| Optimized continuous thicknesses: |

| 0.3795; 0.5878;0.7792;0.9563;1.1177;1.2414;1.4012;1.5763;1.6843;1.7651;1.8386 |

| Resulting thicknesses using sizing optimization with continuous design variables |

|

The difference in the objective functions for the standard and discrete

optimization is less than 2% and the constraints are fulfilled within an

error of 0.001 in this example.