Sizing Optimization for Circular Beams | ||

| ||

Supported Finite Element Features for Circular Beams

The circular beam type based on the Timoshenko beam element formulation is supported for optimization. The corresponding element type definition is summarized in the following table for different solvers:

| Solver | Element type definition |

|---|---|

| Abaqus | *ELEMENT, TYPE=B31 |

| ANSYS® | ET, 1, 188 |

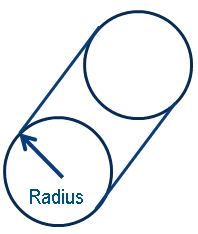

| Circular beam |

|---|

|

As shown in the above picture, the radii of circular beams are supported as design variables. Thus, the following cross section property definition is supported for sizing optimization:

| Solver | Cross section definition |

|---|---|

| Abaqus | *BEAM SECTION, SECTION = CIRC |

| ANSYS® | SECTYPE,1,BEAM,CSOLID SECDATA,25., |

The radii of the circular beam sections can be optimized simultaneously with the elemental shell thicknesses. Outside of the design area, any type of elements can be applied. In the design area, linear and nonlinear material behavior is allowed (that is, plasticity or other geometrical nonlinearities). Contact and constant temperature loadings are supported in context of sizing optimization for circular beams. In addition, both linear static and linear modal type analysis are supported.

The main features and the corresponding comments are summarized in the following table:

| Features | Comment |

|---|---|

| Simultaneously usage of circular beams and shells | Supported |

| Contact | Supported, also for design elements |

| Constitutive nonlinear modeling outside the design area | Supported |

| Constitutive nonlinear materials in design area | Supported |

| Temperature loading | Design independent temperature loading is supported |

| Geometrical nonlinearities | Supported |

| Linear static analysis | Supported |

| Linear modal analysis | Supported |

| Steady-state dynamics | Supported |

Optimization Formulation Options for Circular Beams

All the existing design responses except stresses are supported for sizing optimization with circular beams and can be used for constraints and objective function definitions. All the symmetry constraints available in the sizing module can be applied simultaneously with variable bounds and clustering on design radii. The number of load cases is not limited. DRESPs from static, modal (eigenfrequency) and frequency response (also vibroacoustic) analyses are supported. All the mentioned features are summarized in the following table:

| Feature | Comment |

|---|---|

| DRESPs for static load cases | Supported; for example, Stiffness, Displacements, Forces … |

| Multiple load cases | Supported, arbitrary number |

| DRESPs for modal eigenfrequency analysis | Supported, eigenfrequencies |

| DRESPs for frequency response analysis | Supported, also vibroacoustics |

| Mass | Supported |

| COG and Inertia | Supported |

| Symmetry constraints | Supported, various constraints |

| Variable bounds and clustering | Supported |

| DRESPs with stresses | Not supported |

Limitations

The limitations of sizing optimization for circular beams are as follows:

- Only Abaqus and ANSYS® solvers are supported.

- Only circular beam section type is supported with radius as design variable:

Solver Cross section definition Abaqus *BEAM SECTION, SECTION = CIRCANSYS® SECTYPE,1,BEAM,CSOLID SECDATA,25., -

Only the Timoshenko type beam element is supported:

Solver Element type definition Abaqus *ELEMENT, TYPE=B31ANSYS® ET, 1, 188 - Design responses with stresses are not supported.

Introduction Example for Abaqus

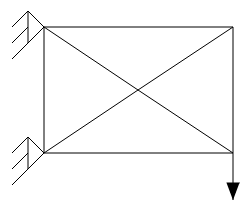

Within this example, the definition of a sizing optimization problem for circular beams is demonstrated. We consider the following model with the illustrated boundary conditions.

| Mechanical model |

|---|

|

The model corresponds to a cantilever beam that consists of 8 elements. It is supported on the left nodes and loaded at the right bottom node.

The corresponding Abaqus input file is given below:

*Heading

** Job name: example Model name: Model-1

** Generated by: Abaqus/CAE 6.14-2

*Preprint, echo=NO, model=NO, history=NO, contact=NO

** PART INSTANCE: Part-1-1

*Node

1, -1., 0.600000024, 0.

2, 0., -0.100000001, 0.

3, 1., -0.800000012, 0.

4, -1., -0.800000012, 0.

5, 1., 0.600000024, 0.

*Element, type=B31

1, 1, 2

2, 2, 3

3, 4, 3

4, 4, 2

5, 2, 5

6, 5, 1

7, 1, 4

8, 3, 5

*Nset, nset=Part-1-1_Set-1, generate

1, 5, 1

*Elset, elset=Part-1-1_Set-1, generate

1, 8, 1

*Nset, nset=Part-1-1_Set-4, generate

1, 5, 1

*Elset, elset=Part-1-1_Set-4, generate

1, 8, 1

*Nset, nset=Part-1-1_Set-5, generate

1, 5, 1

*Elset, elset=Part-1-1_Set-5, generate

1, 8, 1

*Orientation, name=Part-1-1-Ori-1

1., 0., 0., 0., 1., 0.

1, 0.

** Section: Section-1 Profile: Profile-1

*Beam Section, elset=Part-1-1_Set-1, material=steel,

temperature=GRADIENTS, section=CIRC

0.1

0.,0.,1.

*System

*Nset, nset=Set-1

3,

*Nset, nset=Set-2

1, 4

*Nset, nset=Set-3

3, 5

*Nset, nset=_PickedSet7

3,

*Nset, nset=_PickedSet8

3,

** MATERIALS

*Material, name=steel

*Density

7850.,

*Elastic

2e+11, 0.33

** STEP: Step-1

*Step, name=Step-1, nlgeom=NO

*Static

1., 1., 1e-05, 1.

** BOUNDARY CONDITIONS

** Name: BC-1 Type: Symmetry/Antisymmetry/Encastre

*Boundary

Set-2, ENCASTRE

** LOADS

** Name: Load-1 Type: Concentrated force

*Cload

_PickedSet8, 2, 1e+06

** OUTPUT REQUESTS

*Restart, write, frequency=0

** FIELD OUTPUT: F-Output-1

*Output, field, variable=PRESELECT

** HISTORY OUTPUT: H-Output-1

*Output, history, variable=PRESELECT

*End Step

The corresponding Tosca Structure parameter file is given in the following.

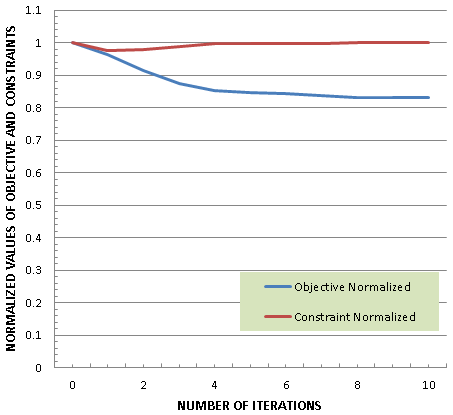

For the present optimization, we maximize the stiffness by minimizing the deflection and at the same time we keep the original mass of the structure. The original mass is enforced using a relative constraint of exactly one. The initial radii are equal to 0.1. The upper and lower bounds on the radii are set to 0.12 and 0.01.

FEM_INPUT

ID_NAME = example

FILE = example.inp

END_

DRESP

ID_NAME = Disp

LIST = NO_LIST

DEF_TYPE = SYSTEM

TYPE = DISP_ABS

ND_GROUP = _PickedSet7

GROUP_OPER = MAX

LC_SET = ALL, 1, ALL, MAX

END_

DRESP

ID_NAME = Mass

LIST = NO_LIST

DEF_TYPE = SYSTEM

TYPE = WEIGHT

EL_GROUP = ALL_ELEMENTS

GROUP_OPER = SUM

END_

DV_SIZING

ID_NAME = Task-1_DESIGN_AREA_

EL_GROUP = ALL_ELEMENTS

END_

DVCON_SIZING

ID_NAME = MY_DVCON_SIZING

CHECK_TYPE = THICKNESS_BOUNDS

EL_GROUP = ALL_ELEMENTS

LOWER_BOUND = 0.01

UPPER_BOUND = 0.12

MAGNITUDE = ABS

END_

OBJ_FUNC

ID_NAME = Minimize_Disp

DRESP = Disp, 1.

TARGET = MIN

END_

CONSTRAINT

ID_NAME = Weight_100

DRESP = Mass

MAGNITUDE = REL

LE_VALUE = 1

END_

OPTIMIZE

ID_NAME = Task-1

DV = Task-1_DESIGN_AREA_

OBJ_FUNC = Minimize_Disp

CONSTRAINT = Weight_100

STRATEGY = SIZING_SENSITIVITY

DVCON = MY_DVCON_SIZING

END_

EXIT

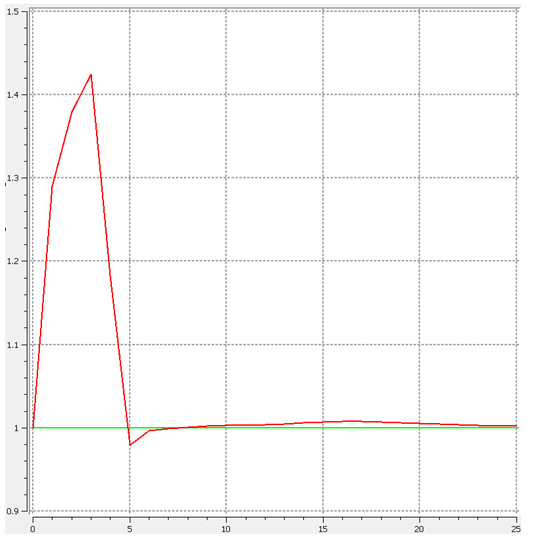

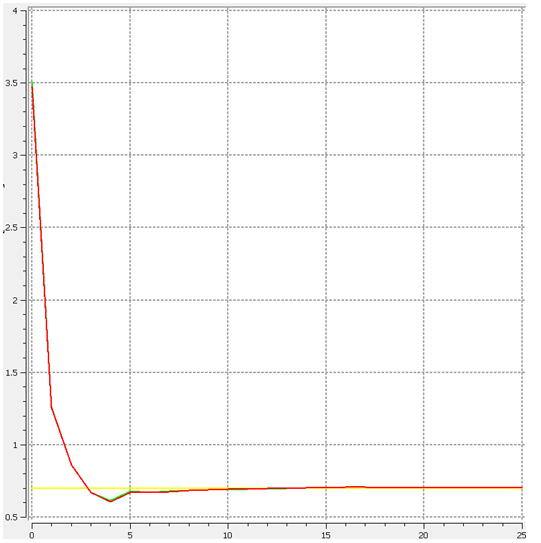

The optimization results are shown in the following figures. The displacement value of the right bottom node is decreased, and the structural volume corresponds to its initial value. The upper and lower bounds of design variables are not violated.

| Optimization history | Optimized radii | Thickness |

|---|---|---|

|

|

|

Introduction Example for ANSYS®

Within this example, the definition of a sizing optimization problem for circular beams is demonstrated. In particular, there is only one beam with one fixed node (left on the picture) and fixed moment of inertia. In addition, there is a force applied on the other node along the Z direction.

| Mechanical model |

|---|

|

The corresponding ANSYS® input file is given below:

! Model name: thick_beam.cdb

/PREP7

/NOPR

LOCAL,R5.0,LOC,11,0,-45.,-17.8483,11.7365

LOCAL,R5.0,ANG,11,0,0.,-90.,0.

LOCAL,R5.0,PRM,11,0,1.,1.

CSYS,11

N,230857,0.,9.98750019,100.

N,230858,0.,9.98649979,0.

CSYS,0

MP,EX,1,10.

MP,PRXY,1,0.3

MP,DENS,1,7.85E-9

ET,1,188

SECNUM,1

SECTYPE,1,BEAM,CSOLID,Beam Section,0

SECOFFSET,SHRC,,,,,,

SECDATA,25.,,,,,,,,,

EBLOCK,19,SOLID

(19i8)

1 1 0 1 0 0 0 0 2 0 1274067 230857 230858

-1

D,230857,ALL,0.,0.

/SOLU

!

! L O A D - S T E P S

!Anonymous Ansys Step 1

!

TIME,1.

!

F,230858,FZ,50.,0.

solve

FINISH

The corresponding Tosca Structure parameter file is given below. For the present optimization, we maximize the stiffness by minimizing the deflection. The initial radius is equal to 25.0 units.

FEM_INPUT

ID_NAME = MY_INPUT_FILES

FILE = thick_beam.cdb, ansys

END_

DRESP

ID_NAME = DRESP_DISP

DEF_TYPE = SYSTEM

TYPE = DISP_ABS

NODE = 230858

CS_REF = CS_0

END_

DRESP

ID_NAME = DRESP_VOL

DEF_TYPE = SYSTEM

TYPE = WEIGHT

EL_GROUP = ALL_ELEMENTS

END_

OBJ_FUNC

ID_NAME = MY_OBJ_FUNC

TARGET = MIN

DRESP = DRESP_VOL, ,

END_

CONSTRAINT

ID_NAME = CONSTRAINT_DISP

MAGNITUDE = ABS

DRESP = DRESP_DISP

LE_VALUE = 0.9

END_

DV_SIZING

ID_NAME = DESIGN_AREA

EL_GROUP = ALL_ELEMENTS

END_

OPTIMIZE

ID_NAME = OPTIMIZE_1_SIZING_OPTIMIZATION

DV = DESIGN_AREA

OBJ_FUNC = MY_OBJ_FUNC

CONSTRAINT = CONSTRAINT_DISP

STRATEGY = SIZING

END_

STOP

ID_NAME = GLOBAL_STOP_CONDITION_1

ITER_MAX = 50

END_

Result: The output of the optimization shows that the radius of the beam is now thicker with 5 more units (R = 30).

Optimization Example: Combined Optimization of Outer Shell Elemental Thicknesses and Elemental radii of Inner Ground Structure

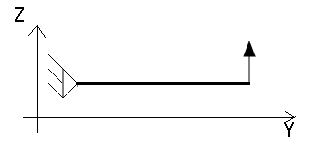

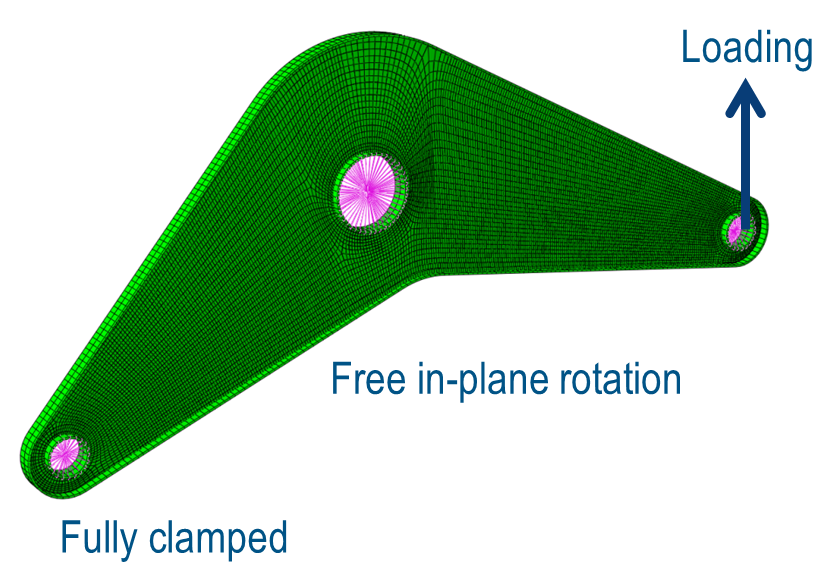

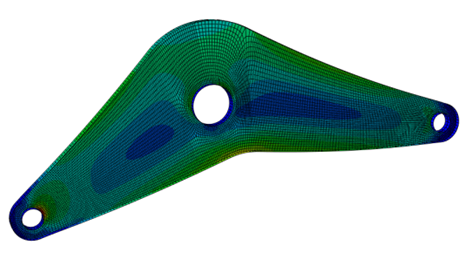

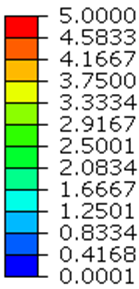

We consider the following model with the illustrated boundary conditions, pictured initial deformation, and the corresponding initial stress.

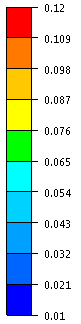

| Mechanical model | Deformation | Stress |

|---|---|---|

|

|

|

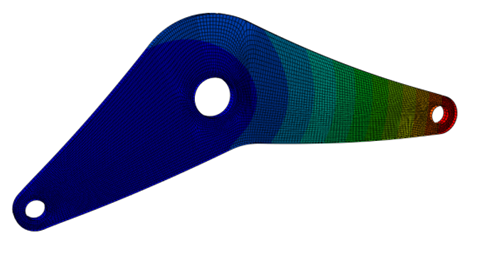

The structural mass is to be minimized, while keeping the displacement at loading point less than 0.6mm. The inner structure is consisting of either shell thicknesses or lattice build of circular beams. The design variables either the inner shell thicknesses or the radii of the lattice simultaneously with the elemental thicknesses of the other shell reinforcements.

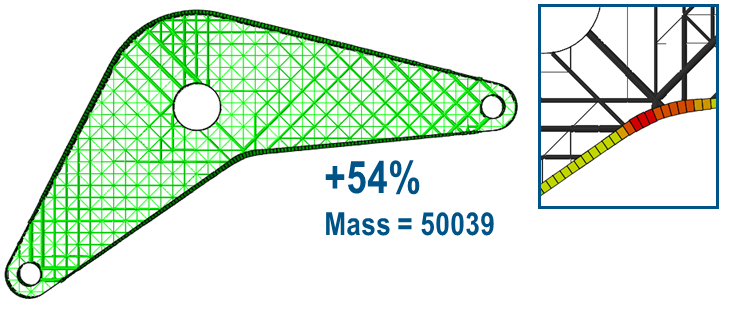

The optimization results are shown in the following figure:

| Thickness | Free continuous shell thickness | Triangular fine lattice |

|---|---|---|

|

|

|

| Thickness | Triangular medium lattice | Triangular coarser lattice |

|---|---|---|

|

|

|

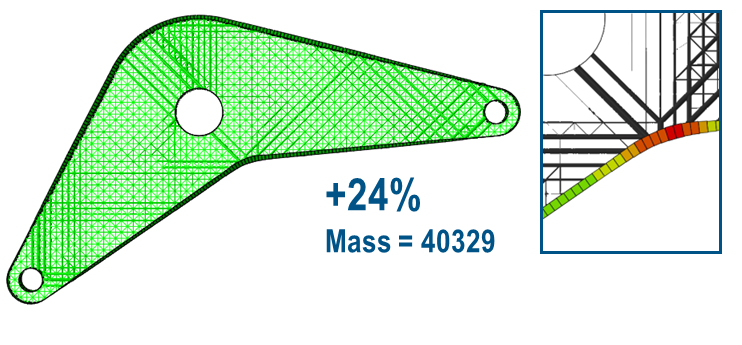

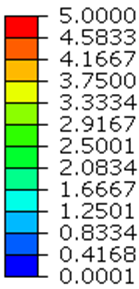

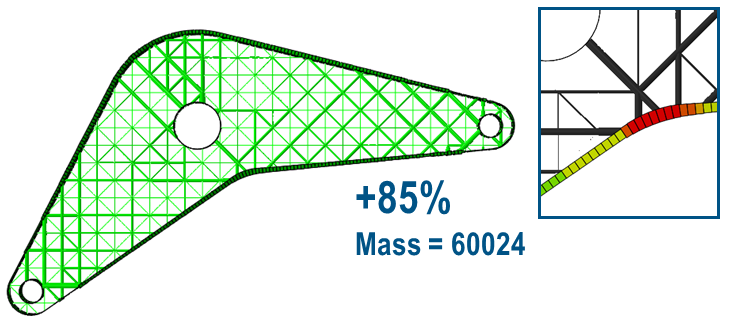

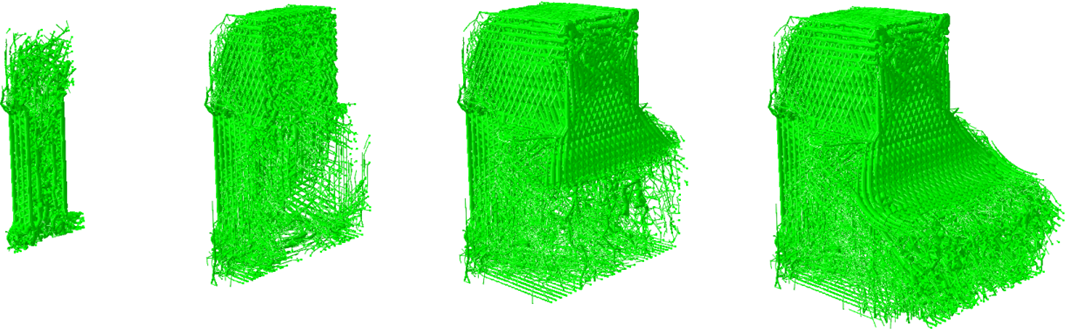

Optimization Example: Lattice Optimization of Door Stop.

We consider the following model.

|

Optimization Objectives:

- Maximize stiffness

- Keep the original structural mass

- Displacement for interface constraints

Radius of circular beam element:

- Initial: 0.18

- Lower bound: 0.00001 (approximates void)

- Upper bound: 0.7 (289%)

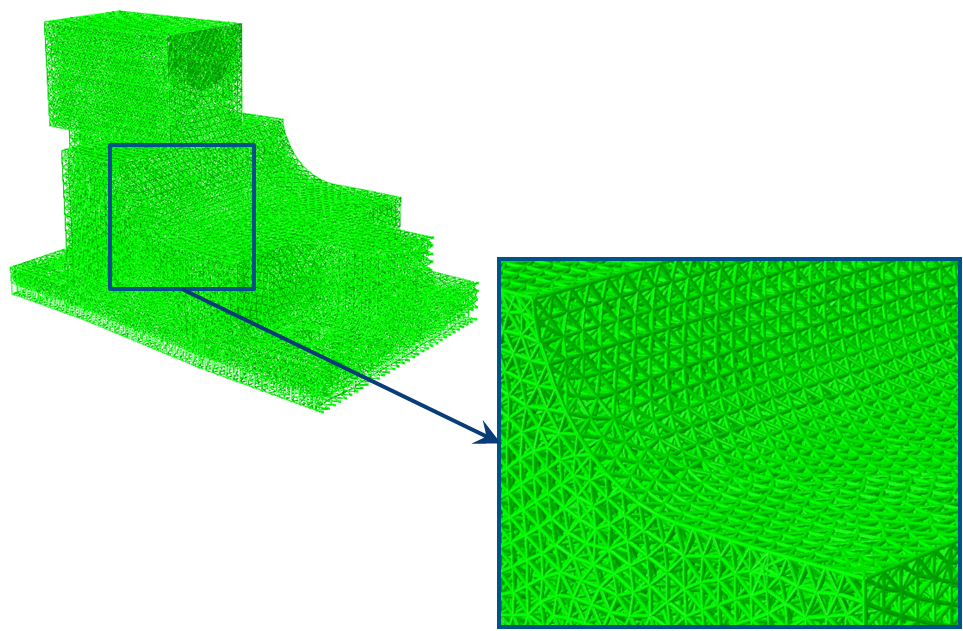

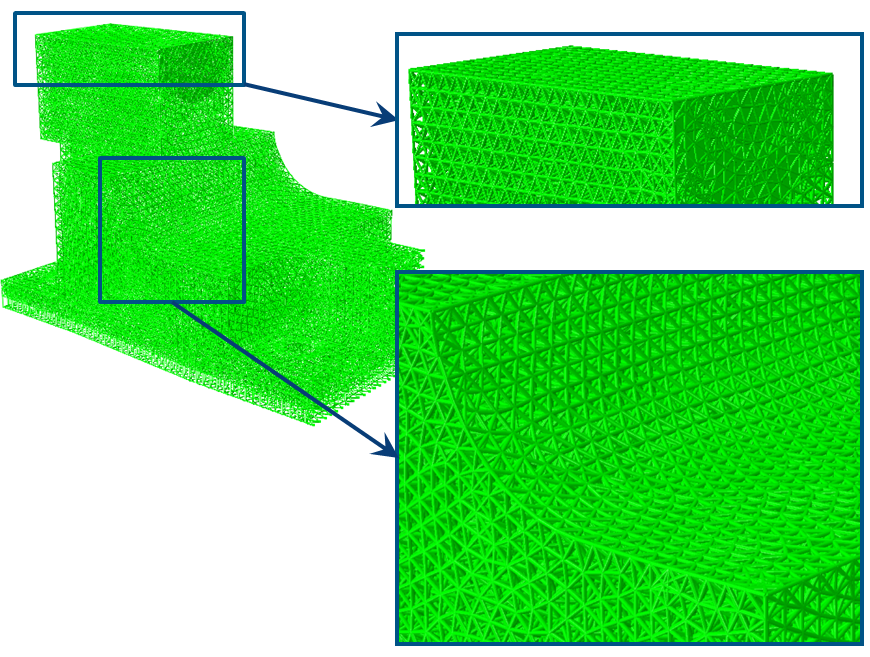

The following figure represents the section cuts for the original structure having uniform radius sections for the entire structure:

|

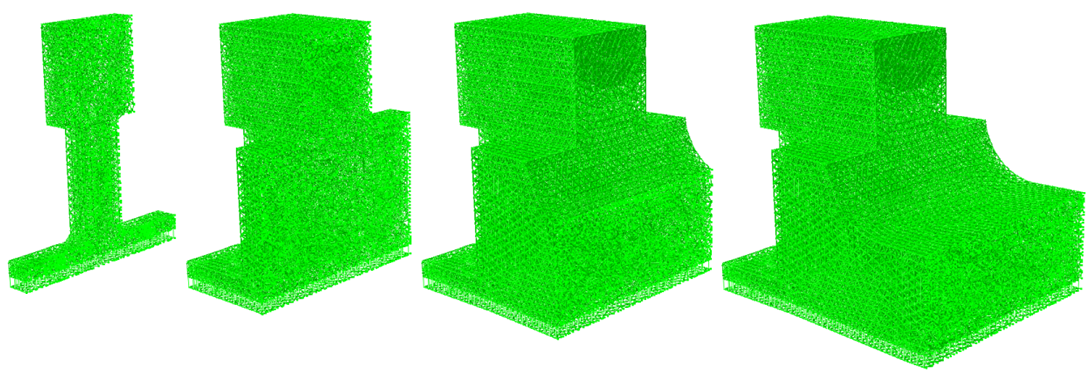

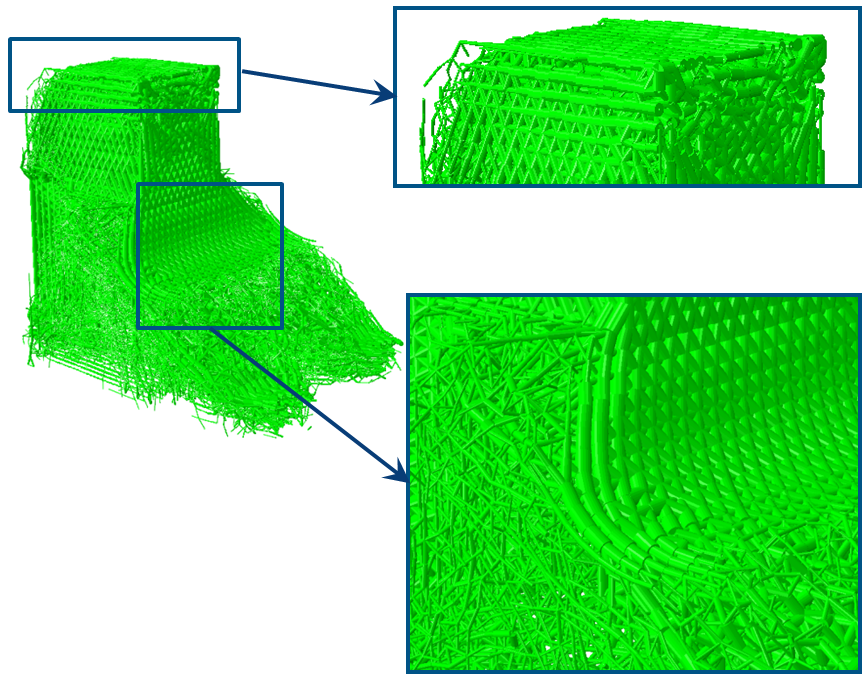

The next figure shows the radius distribution of the section cuts for the optimized structure:

|

Some enlarged details of the initial and the optimized structures are pictured in the following figure:

| Initial radii | Optimized radii |

|---|---|

|

|

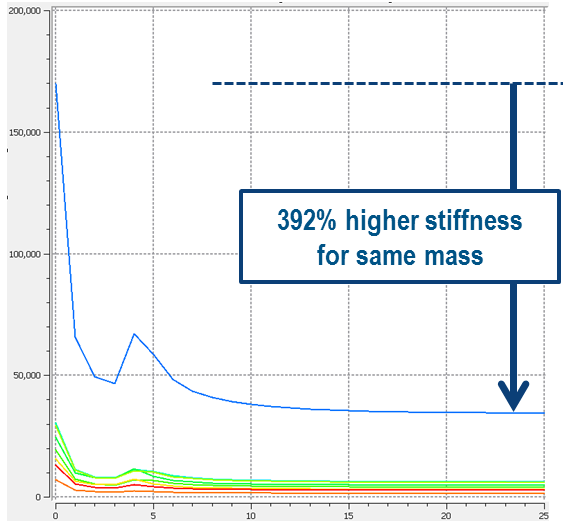

The following figures show the optimization iteration history for the design responses being the stiffness energy measure for the objective and mass and displacement as constraints:

| Stiffness energy measure | Mass (normalized) | Displacement interface constraints |

|---|---|---|

|

|

|