General Information | ||||

|

| |||

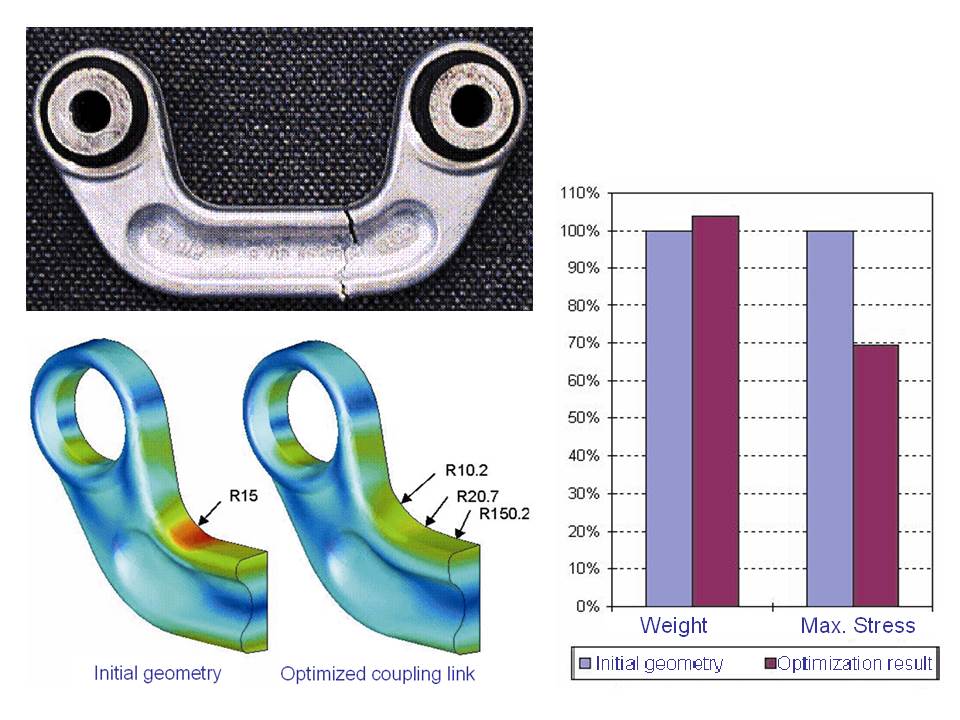

In the following figure, an example of nonparametric shape optimization is demonstrated. (Pictures by courtesy of Audi AG).

|

Typically, the objective function is to minimize stress concentrations. Based on the results of a stress analysis modifications of the surface geometry of a component are performed until the required stress level is reached. This process is usually carried out manually by trial-and-error.

Tosca Structure.shape allows an automation of this improvement process. The surface geometry of a given FE model is modified iteratively based on the FE results, such that the required optimization target is reached. The start model is taken from an existing design, which should be improved, or from a previous topology optimization.

Tosca Structure.shape enables you to perform the following tasks

- Minimization of the equivalent stress

- Maximization of selected natural frequencies

Under the possible restrictions:

- Specification of a volume constraint

- Surface-based manufacturing constraints for casting, forging, stamping, extrusion and drilling

- Minimum and maximum member size

- Symmetry constraints

- Specification of design domain restrictions by FE meshes

- Mesh adjustment and mesh smoothing in each optimization cycle

Additional functionalities like optimization using durability results are available with Tosca Structure.durability. Functionalities like optimization using nonlinear results or optimization of contact areas are available with Tosca Structure.nonlinear.

Sensitivity-Based Shape Optimization

Sensitivity-based shape optimization (SHAPE_SENSITIVITY) makes it possible to define very complex optimization tasks. It has been shown in industrial size examples that the method is very powerful and attractive for problems with many CONSTRAINTs.

The typical problems which can be solved by this algorithm are:

- Minimize volume with stiffness or displacement constraint

- Minimize volume with stress constraint

- Maximize stiffness (linear static) with a volume constraint

- Minimize displacement for critical nodes (linear static) with a volume constraint

- Maximize first eigenvalue (modal) with a volume constraint

- Maximize a certain eigenvalue (using mode tracking)

- Move eigenvalues away from certain frequency (band gap optimization with modal analysis)

| Important:

|

- Analysis Types

-

Analysis type Supported Linear Analysis Yes Linear modal (no pre-tension) Yes Nonlinear contact only, linear material, linear strains (NLGEOM=NO) Yes Nonlinear material (for example, *PLASTICITY) Yes Nonlinear strains (NLGEOM=YES) Yes - Remarks on Boundary Conditions Using Solver Sensitivities SENS_CALC_MODE=SOLVER

-

- Prescribed displacements are supported.

- Temperature preloading is allowed, but must stay constant during optimization.

- TEMPERATURE_FILE is not allowed with sensitivity-based shape optimization.

- Forces, surface forces, gravity forces and contact forces on design nodes are supported.

- Remarks on Boundary Conditions Using Tosca Sensitivities SENS_CALC_MODE=TOSCA

-

- Prescribed displacements are supported.

- Temperature preloading and TEMPERATURE_FILE are NOT allowed.

- Forces, surface forces, gravity forces and contact forces on design nodes are NOT supported as well.