Guidelines for Optimization of Structures with Nonlinear Behavior | ||

| ||

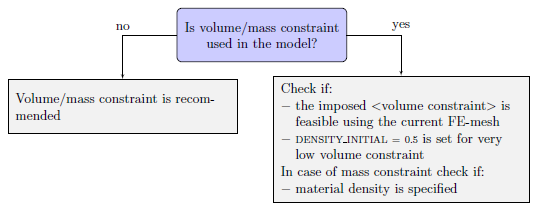

Volume/Mass Constraint in the Model

|

In cases where volume/mass constraints are in the model, it is important to verify if the

corresponding constraint values are feasible with respect to the given FE-mesh size.

For example, if we consider a square plate that is discretized by 9 square elements

and use a relative volume constraint of 1/9, then we cannot expect a black and white

solution where some corners of the structure are connected. Set the

DENSITY_INITIAL = 0.5 in cases where very low volume

constraints (for example 0.05) are used to stabilize the optimization. If the volume

constraint is not satisfied or there are unconnected regions in the resulting

optimized structure, follow the given guidelines. Finer meshing of the structure,

that is, increasing the number of elements appropriate for the volume constraint,

can overcome these problems.

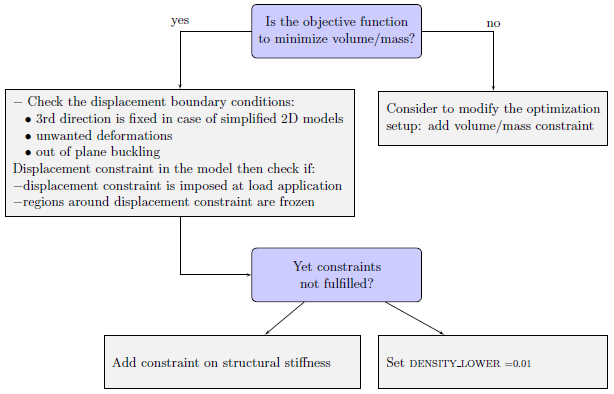

Minimize Volume/Mass as Objective

|

In cases where volume/mass is used as the objective function, follow the procedure recommendation

to avoid convergence issues. Check the displacements boundary conditions with

respect to the third direction if 3D models are used to simulate 2D structures.

Also, look for unwanted deformations and out of plane buckling. In cases where the

model uses displacement constraints, define these constraints at load application

and freeze regions around the displacement constraints. If the above setup does not help

to satisfy the constraints, then impose additional constraints on the structural

stiffness to stabilize the optimization. This is required to avoid structures acting

like compliant mechanisms. If solver convergence issues appear during the

optimization procedure, set DENSITY_LOWER = 0.01. This can help to

reach convergence, but it aids in the creation of mechanism designs (because it

increases the unphysical stiffness of holes) which are not favored in most cases.

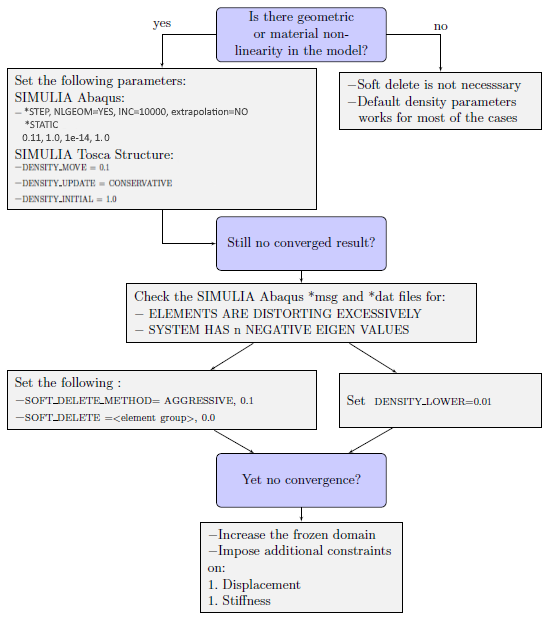

Topology Optimization in the Context of Nonlinear Structural Analysis

|

The above setup is considered to be stable for running topology optimization of structures with

nonlinear behavior. Even though the settings consume more time for convergence, the

optimization can converge in the first attempt. The recommendation for the settings

is: small initial time increment, DENSITY_MOVE = 0.1,

DENSITY_UPDATE = CONSERVATIVE, DENSITY_INITIAL =

1.0. If there are still convergence issues on the solver side, check in

case of Abaqus for the above mentioned warnings in the *.msg and

*.dat files. If those warnings are found, activate the soft delete

procedure by adding SOFT_DELETE_METHOD = AGGRESSIVE, 0.1,

SOFT_DELETE = <element group>, 0.0. This option offers the

possibility of removing soft elements that could be distorted during the

optimization process. Another alternative would be to change

DENSITY_LOWER=0.01. One of the trivial methods of stabilizing a

nonlinear optimization task is by increasing the frozen domain. If convergence

issues retain, impose additional constraints on displacement or structural stiffness

to further stabilize the optimization procedure.

Manufacturing Constraints in the Model

In cases where the model contains manufacturing restrictions:

- It is crucial to set the correct origin of the co system and the axis corresponding to the restrictions in the parameter file.

- In the case of nonlinear problems, if the optimization ends in the solver convergence issues, the recommendation to remove the manufacturing constraints and solve the convergence issues. After obtaining a converged result, impose the restrictions one after the other.

Thermal Expansion in the Model

For thermal expansion problems, the

recommendation is to use the ENERGY_STIFF_MEASURE design response instead

of the STRAIN_ENERGY design response.

Contact in the Model

For highly nonlinear contact problems,

the automatic stabilization technique offered by the Abaqus solver is the recommendation. This option helps automatically control rigid body motion

before the contact closure restrains such motion, which can be activated by

*CONTACT CONTROLS, STABILIZE command. By default, the auto-frozen option

is activated in Tosca Structure, which affects regions with contact, load, and displacement boundary conditions. Hence,

it is important to deactivate the Auto frozen option AUTO_FROZEN=OFF to

acquire the contact regions as design domain in cases where it is required. Note, this

setting can lead to solver convergence issues.

Minimize Stress as Objective

In cases where stress design responses are used to define the objective function, the recommendation is to give reference values for the corresponding design responses. If stress design responses are used in the model, the recommendation is to use sensitivities calculated by the Abaqus solver.