-

Define the Design Area (DV_SIZING):

DV_SIZING

ID_NAME = Opt_Plate_DESIGN_AREA_

EL_GROUP = ALL_ELEMENTS

END_

-

To define the Objective Function, do the following:

-

Define a Design Response (DRESP) with the volume of the

model:

DRESP

ID_NAME = Vol

LIST = NO_LIST

DEF_TYPE = SYSTEM

TYPE = VOLUME

EL_GROUP = ALL_ELEMENTS

GROUP_OPER = SUM

END_

-

Reference the Design Response in the Objective Function

(OBJ_FUNC) and set the TARGET to MIN:

OBJ_FUNC

ID_NAME = Min_Vol

DRESP = Vol

TARGET = MIN

END_

-

To define the stress constraint, do the following:

-

Define a Design Response (DRESP) that contains the absolute

von Mises stresses appearing in the model:

DRESP

ID_NAME = mises_stress

LIST = NO_LIST

DEF_TYPE = SYSTEM

TYPE = SIG_SENS_MISES

EL_GROUP = ALL_ELEMENTS

GROUP_OPER = MAX

LC_SET = ALL, 1, ALL

END_

-

Reference the Design Response in a constraint (CONSTRAINT)

and restrict it to 425 MPa:

CONSTRAINT

ID_NAME = Max_stress

DRESP = mises_stress

MAGNITUDE = ABS

LE_VALUE = 425

END_

-

Set up the optimization

-

Define an element group (Cluster1, Cluster2,... (predefined

in the example model)) for each of the clustering areas and assign them to a

clustering design variable constraint as follows:

DVCON_SIZING

ID_NAME = CLUSTERING

EL_GROUP = Cluster1

EL_GROUP = Cluster2

EL_GROUP = Cluster3

EL_GROUP = Cluster4

EL_GROUP = Cluster5

EL_GROUP = Cluster6

EL_GROUP = Cluster7

EL_GROUP = Cluster8

EL_GROUP = Cluster9

EL_GROUP = Cluster10

EL_GROUP = Cluster11

EL_GROUP = Cluster12

EL_GROUP = Cluster13

EL_GROUP = Cluster14

EL_GROUP = Cluster15

EL_GROUP = Cluster16

EL_GROUP = Cluster17

EL_GROUP = Cluster18

EL_GROUP = Cluster19

EL_GROUP = Cluster20

EL_GROUP = Cluster21

EL_GROUP = Cluster22

EL_GROUP = Cluster23

EL_GROUP = Cluster24

CHECK_TYPE = CLUSTER

END_

-

Define a DVCON_SIZING to increase the upper and lower bounds

of the element thicknesses:

DVCON_SIZING

ID_NAME = THICK_BOUNDS

EL_GROUP = ALL_ELEMENTS

CHECK_TYPE = THICKNESS_BOUNDS

MAGNITUDE = ABS

LOWER_BOUND = 0.5

UPPER_BOUND = 2

END_

-

Reference the Design Variables, Objective Function, and

constraints in the OPTIMIZE command:

OPTIMIZE

ID_NAME = Opt_Plate

DV = Opt_Plate_DESIGN_AREA_

OBJ_FUNC = Min_Vol

CONSTRAINT = Max_stress

DVCON = CLUSTERING

DVCON = THICK_BOUNDS

STRATEGY = SIZING_SENSITIVITY

END_

-

Define specific settings for optimization in OPT_PARAM command:

OPT_PARAM

ID_NAME = Plastic_Plate_OPT_PARAM_

OPTIMIZE = Plastic_Plate

AUTO_FROZEN = LOAD

THICKNESS_UPDATE = CONSERVATIVE

THICKNESS_MOVE = 0.25

STOP_CRITERION_LEVEL = BOTH

STOP_CRITERION_OBJ = 0.001

STOP_CRITERION_THICKNESS = 0.005

STOP_CRITERION_ITER = 4

END_

Here it is important to mention that optimization with

nonlinearities should run with

THICKNESS_UPDATE = CONSERVATIVE to improve

convergence.

-

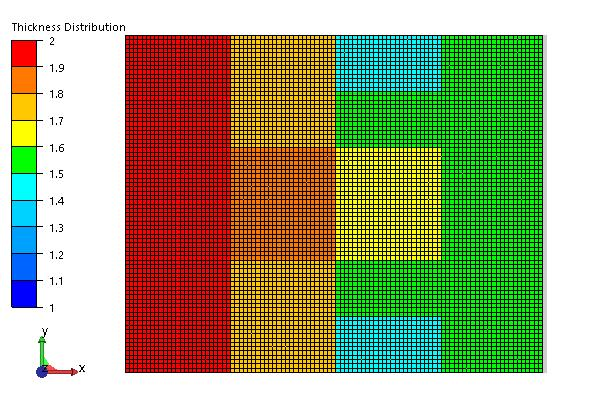

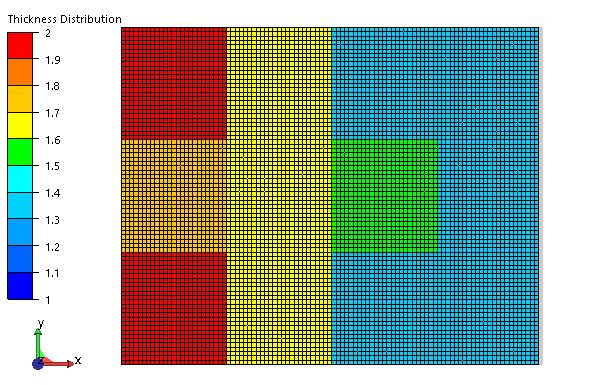

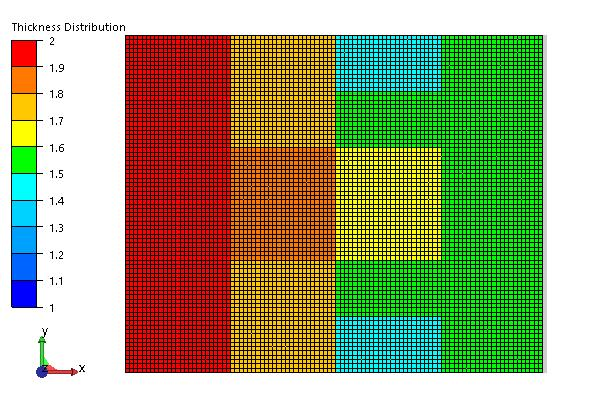

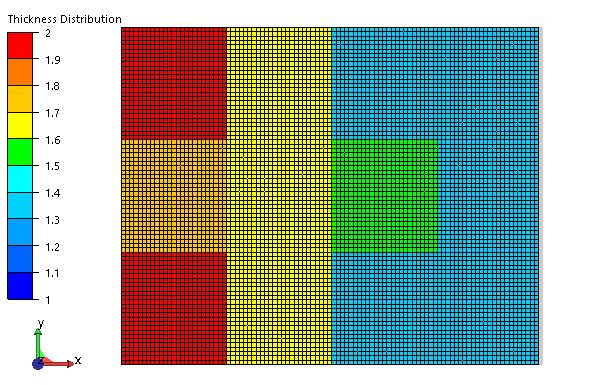

The optimized results including nonlinear kinematics (NLGEOM=ON):

-

Optimum with elastic material:

Optimum when ignoring nonlinear effects limits the

optimizer from removing the material if one of the element reaches the stress

constraint value.

-

Optimum with elastic-plastic material:

Optimum when considering nonlinear effects contains

more regions with yield stress, allowing the optimizer to remove more material

compared to the elastic case.

|