Optimize the Bending Plate Model | ||

| ||

-

Define the Design Area (DV_SIZING):

DV_SIZING ID_NAME = Opt_Plate_DESIGN_AREA_ EL_GROUP = ALL_ELEMENTS END_

-

To define the Objective Function, do the following:

-

Define a Design Response (DRESP) with the displacement in

X-direction of the nodes on the right edge:

DRESP ID_NAME = Disp_x LIST = NO_LIST DEF_TYPE = SYSTEM TYPE = DISP_X_ABS ND_GROUP = Z-LOAD GROUP_OPER = MAX LC_SET = ALL, 1, ALL END_

-

Reference the Design Response in the Objective Function

(OBJ_FUNC) and set the TARGET to MINMAX:

OBJ_FUNC ID_NAME = Min_Disp_x DRESP = Disp_x, 1. TARGET = MINMAX END_

The maximum displacement out of the node set will be minimized.

-

Define a Design Response (DRESP) with the displacement in

X-direction of the nodes on the right edge:

-

To define the volume constraint, do the following:

-

Define a Design Response (DRESP) that contains the sum of the

total volume of the optimization group:

DRESP ID_NAME = Vol LIST = NO_LIST DEF_TYPE = SYSTEM TYPE = VOLUME EL_GROUP = ALL_ELEMENTS GROUP_OPER = SUM END_

-

Reference the Design Response in a constraint (CONSTRAINT)

and restrict it to 50% of the initial volume:

CONSTRAINT ID_NAME = Max_Vol DRESP = Vol MAGNITUDE = REL LE_VALUE = 0.9 END_

-

Define a Design Response (DRESP) that contains the sum of the

total volume of the optimization group:

-

Set up the optimization.

-

Define an element group (Cluster1, Cluster2,... [predefined

in the example model]) for each of the clustering areas and assign them to a

clustering design variable constraint as follows:

DVCON_SIZING ID_NAME = CLUSTERING EL_GROUP = Cluster1 EL_GROUP = Cluster2 EL_GROUP = Cluster3 EL_GROUP = Cluster4 EL_GROUP = Cluster5 EL_GROUP = Cluster6 EL_GROUP = Cluster7 EL_GROUP = Cluster8 EL_GROUP = Cluster9 EL_GROUP = Cluster10 EL_GROUP = Cluster11 EL_GROUP = Cluster12 EL_GROUP = Cluster13 EL_GROUP = Cluster14 EL_GROUP = Cluster15 EL_GROUP = Cluster16 EL_GROUP = Cluster17 EL_GROUP = Cluster18 EL_GROUP = Cluster19 EL_GROUP = Cluster20 EL_GROUP = Cluster21 EL_GROUP = Cluster22 EL_GROUP = Cluster23 EL_GROUP = Cluster24 CHECK_TYPE = CLUSTER END_

-

Reference the Design Variables, Objective Function, and

constraints in the OPTIMIZE command:

OPTIMIZE ID_NAME = Opt_Plate DV = Opt_Plate_DESIGN_AREA_ OBJ_FUNC = Min_Disp_x CONSTRAINT = Max_Vol DVCON = CLUSTERING STRATEGY = SIZING_SENSITIVITY END_

-

Define specific settings for optimization in the OPT_PARAM

command:

OPT_PARAM ID_NAME = Bending_Plate_NL_OPT_PARAM_ OPTIMIZE = Bending_Plate_NL AUTO_FROZEN = LOAD THICKNESS_UPDATE = CONSERVATIVE THICKNESS_MOVE = 0.25 STOP_CRITERION_LEVEL = BOTH STOP_CRITERION_OBJ = 0.001 STOP_CRITERION_THICKNESS = 0.005 STOP_CRITERION_ITER = 4 END_

Important: Optimization with nonlinearities should run with THICKNESS_UPDATE = CONSERVATIVEto improve convergence.

-

Define an element group (Cluster1, Cluster2,... [predefined

in the example model]) for each of the clustering areas and assign them to a

clustering design variable constraint as follows:

-

Set an additional command in the OPTIONS command:

OPTIONS IGNORE_NUM_OF_OBJF_TERMS = YES END_

This is needed because, by default, Tosca Structure allows only 50 terms in the objective definition. In this example, there are 79 nodes to be optimized. Thus, by ignoring the warning the optimization is allowed to run freely.

-

-

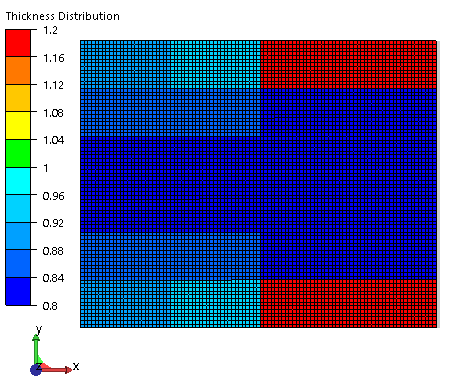

Optimum without considering nonlinear effects.

Optimum when ignoring nonlinear effects contains members (at load application) with high thickness along the membrane in order to resist the displacement caused by the tension load (does not account for bending). -

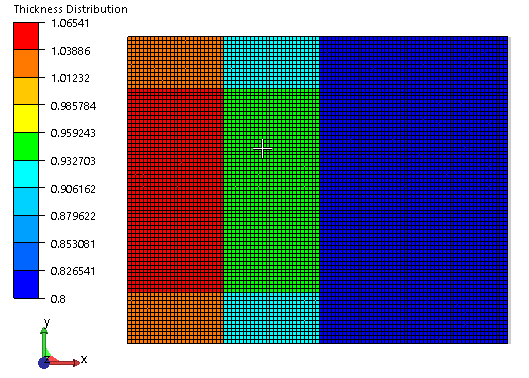

Optimum considering nonlinear effects.

Optimum when considering nonlinear effects results in a structure that resists the bending force (the load in the membrane is very minimal and, hence, not much contribution).

-

Optimum without considering nonlinear effects.